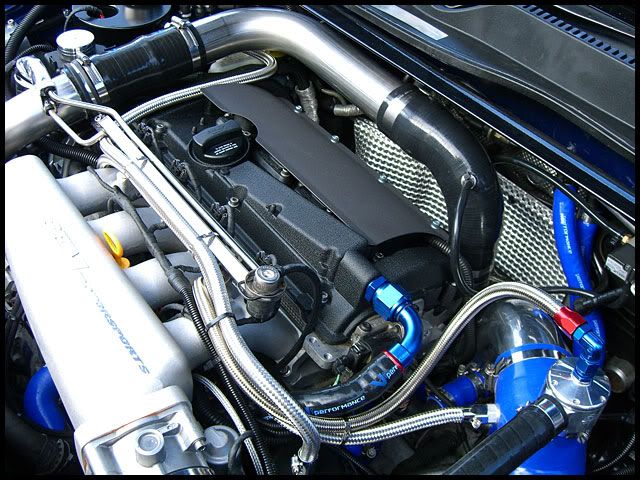

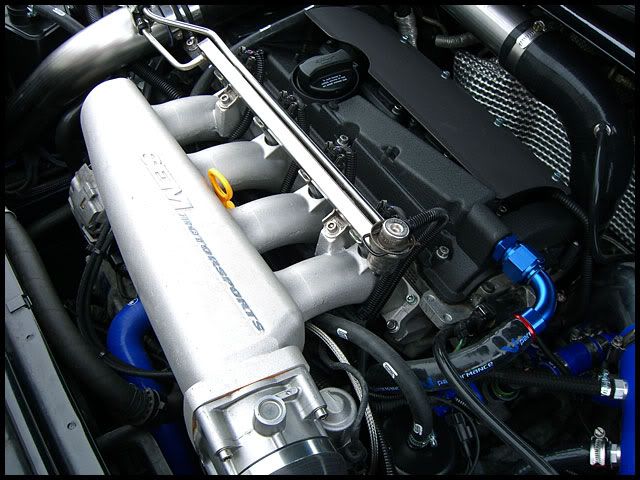

Looks spot on Rob, just keeps getting better.

Your tap in points in the charge pipe for your Apexi are they the revotec ones? I'm needing something similar for my DIY intake pipe.

Your tap in points in the charge pipe for your Apexi are they the revotec ones? I'm needing something similar for my DIY intake pipe.

VERY Nice, Robbie.

VERY Nice, Robbie.

)

)