Time of a long overdue update

Not had much to report on until now as the motor suffered an unwanted movement in the cam timing resulted its premature demise when it dropped a valve back in the end of May. Bugger.

A replacement ABF was sourced and built to the same spec as before with the addition of Supertech one piece Stainless valves, valve springs and titanium retaining caps and a few more bits I cant remember

The stock oilcooler/heat exchanger has been ditched and using a 25 oil cooler mounted to the front of the rad, but underestimated the cooling efficiency of the rad and cooler as getting temperature into it from cold takes ages and I ended up blanking off the additional cooling holes made in the bumper just to keep temperature at normal levels. Also swapped the the mocal sandwich take-off plate to one with an thermostat built in and will be swapping the 25 row cooler to a 13 row item.

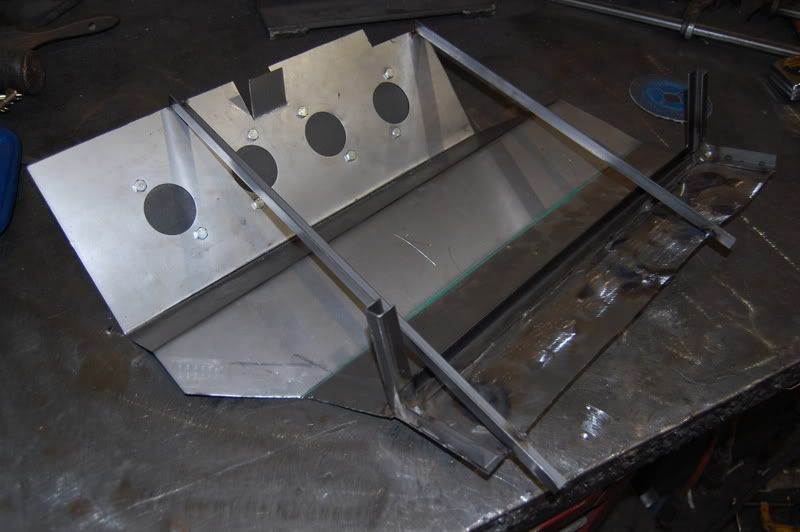

I abandoned the idea of fabricating the airbox out of fibreglass as that was too messy and time consuming when I tried it out or myself. Being metal fabricator by trade, the ovbious solution would be to makes it out of sheet metal welded together

Made a cardboud template first to guage clearences before cutting any metal, At least watching Blue Peter wasn't wasted lol

Working with 0.6mm mild steel, the base as it were has to joggle over coolant and oil cooler pipes

I braced and cut the middle out of the slam panel to make way for the box.

I had originally planned to use pond filter foam as a means of filtration but a panel filter that RobT had made by ITG for the Pickle was so perfect for the box it seemed a no brainer not to use it

Pushing the envelope as to what I can get away without seriously altering the bonnet but allowing for movement at the same time, I had the inlet face of the head machined in a way that the bodies and trumpets point more in the direction of horizontle by about 14 degrees from the original datum.

Need to think up of some method of tilting down the trumpets.....

Thats one side to the box made, got a temporey steel 'lid' made up to assist making up the otherside and to be eplaced with an ally one.

More tommorow

.