-

Guest, 🚨New Stock alert: Premium CUPRA valve caps now available in the store 👉 Order now from the merchandise store

Going to build a race 1m

- Thread starter Manic172

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I had the same problem with the long right handers at Cadwell, lucky the Leon (mk3) there is an in tank solution but when I went to Demon Tweeks they actually advised against (foam filling) it on a Stock car tank as they said it could cause more problems because you would not be able to get the whole tanks filled correctly. As I say I then found the in tank solution and that fixed the issue.

Managed to find someone to make me a horizontal mount swirl pot for mounting underneath. He stocks aeroquip stuff & walbro so said will be easy enough so looks like a decent solution for my setup (hopefully, as long as doesn’t just talk a good game)

makes sense re foam in tank

makes sense re foam in tank

Last edited:

Inside todays (yesterdays) box from turbo zentrum.

Tial motorsport wastegate. Notable the top wastegates money can buy. Used by many motorsport teams around the world.

Very well made, the finish and details are brilliant. The anodising is purfect

. The finish machining and just the work is brilliant.

. The finish machining and just the work is brilliant.

Comes with attachments for the air supply's and for the water cooling too.

The clamps are not just your **** jubilee clips.. proper v band style and with the mating faces for welding to manifolds and down pipes for a proper sealing fit

And all the springs in the world for setting up the pressure internally for the wastegate.

Tial motorsport wastegate. Notable the top wastegates money can buy. Used by many motorsport teams around the world.

Very well made, the finish and details are brilliant. The anodising is purfect

Comes with attachments for the air supply's and for the water cooling too.

The clamps are not just your **** jubilee clips.. proper v band style and with the mating faces for welding to manifolds and down pipes for a proper sealing fit

And all the springs in the world for setting up the pressure internally for the wastegate.

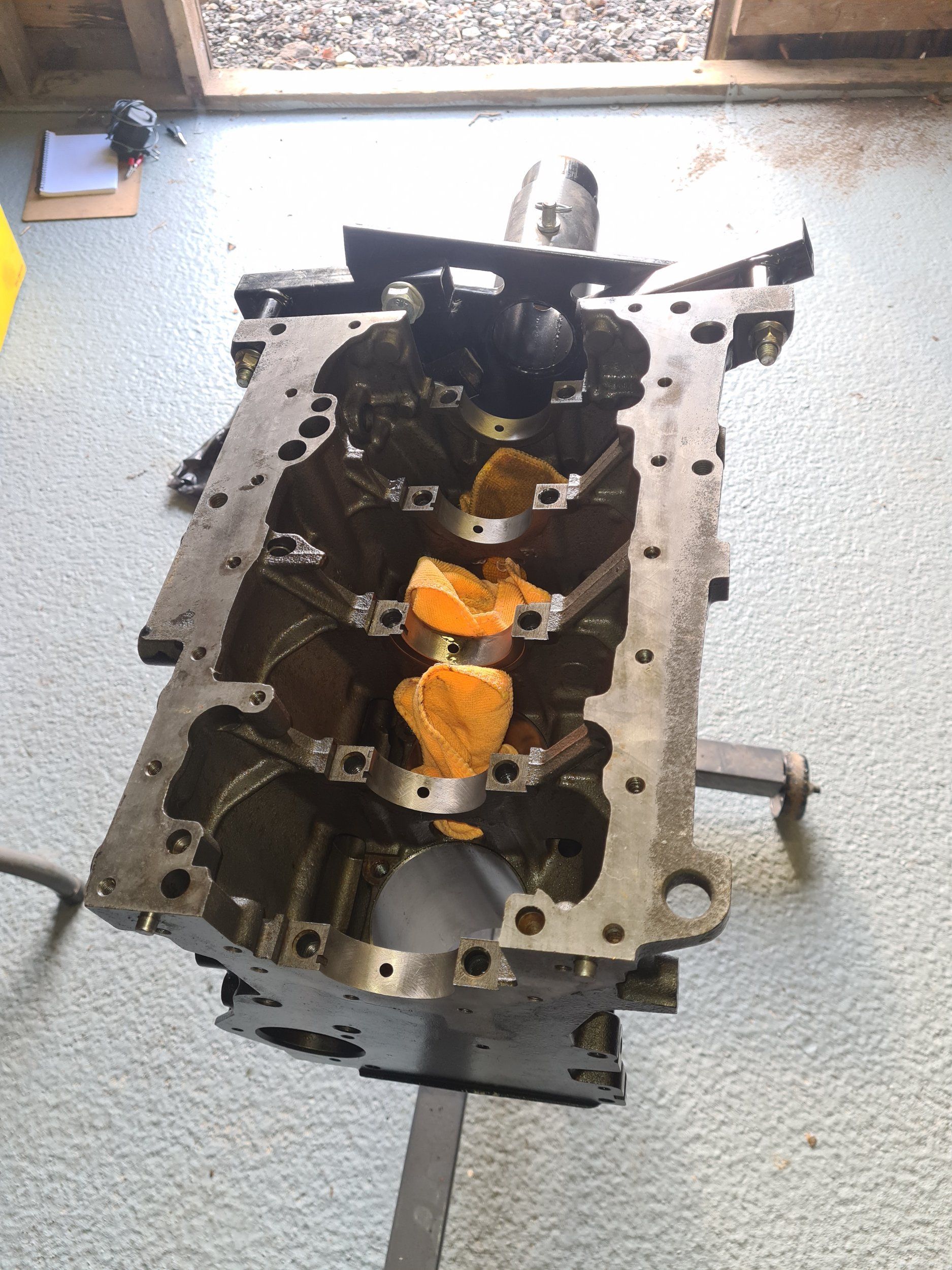

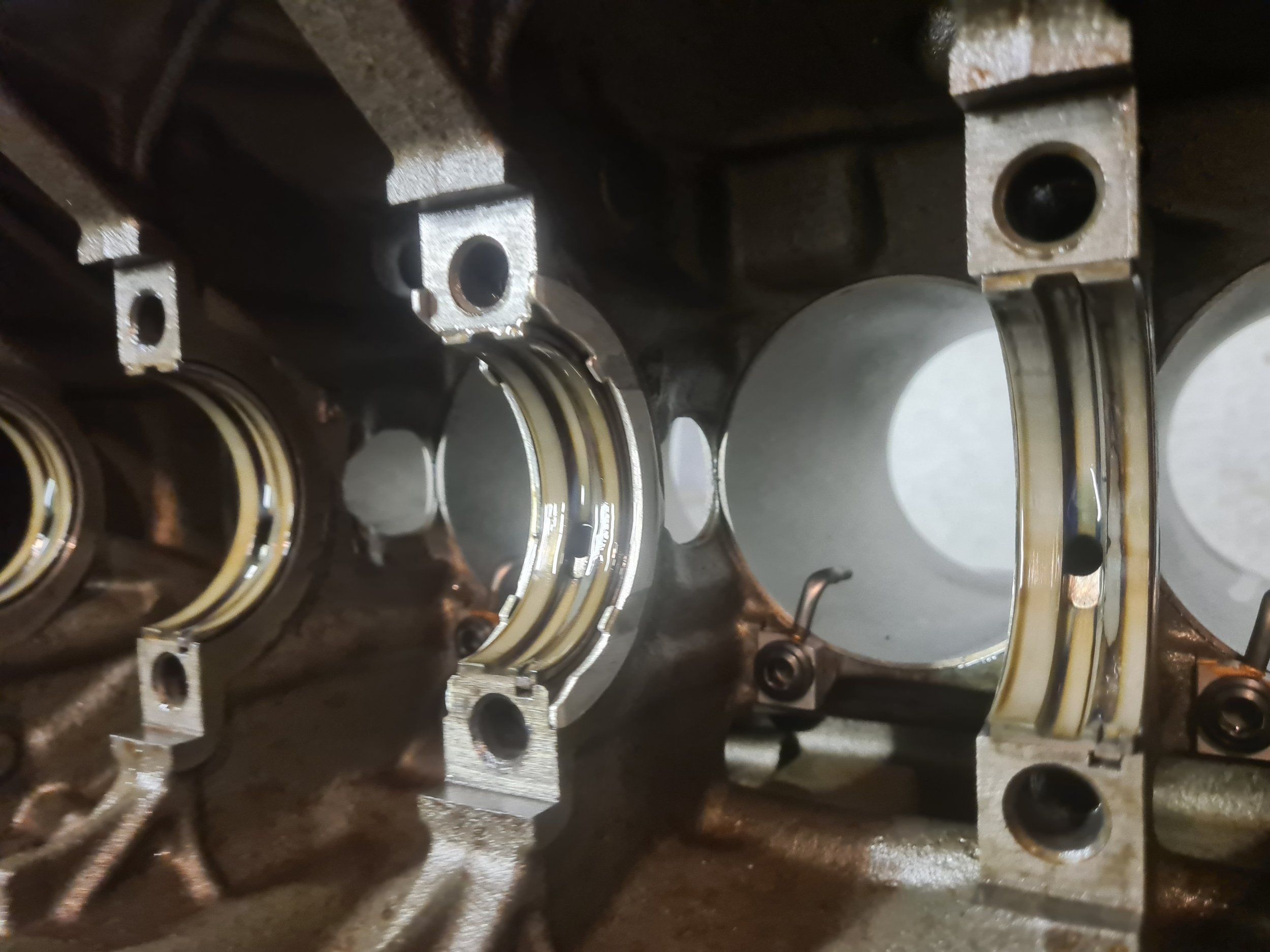

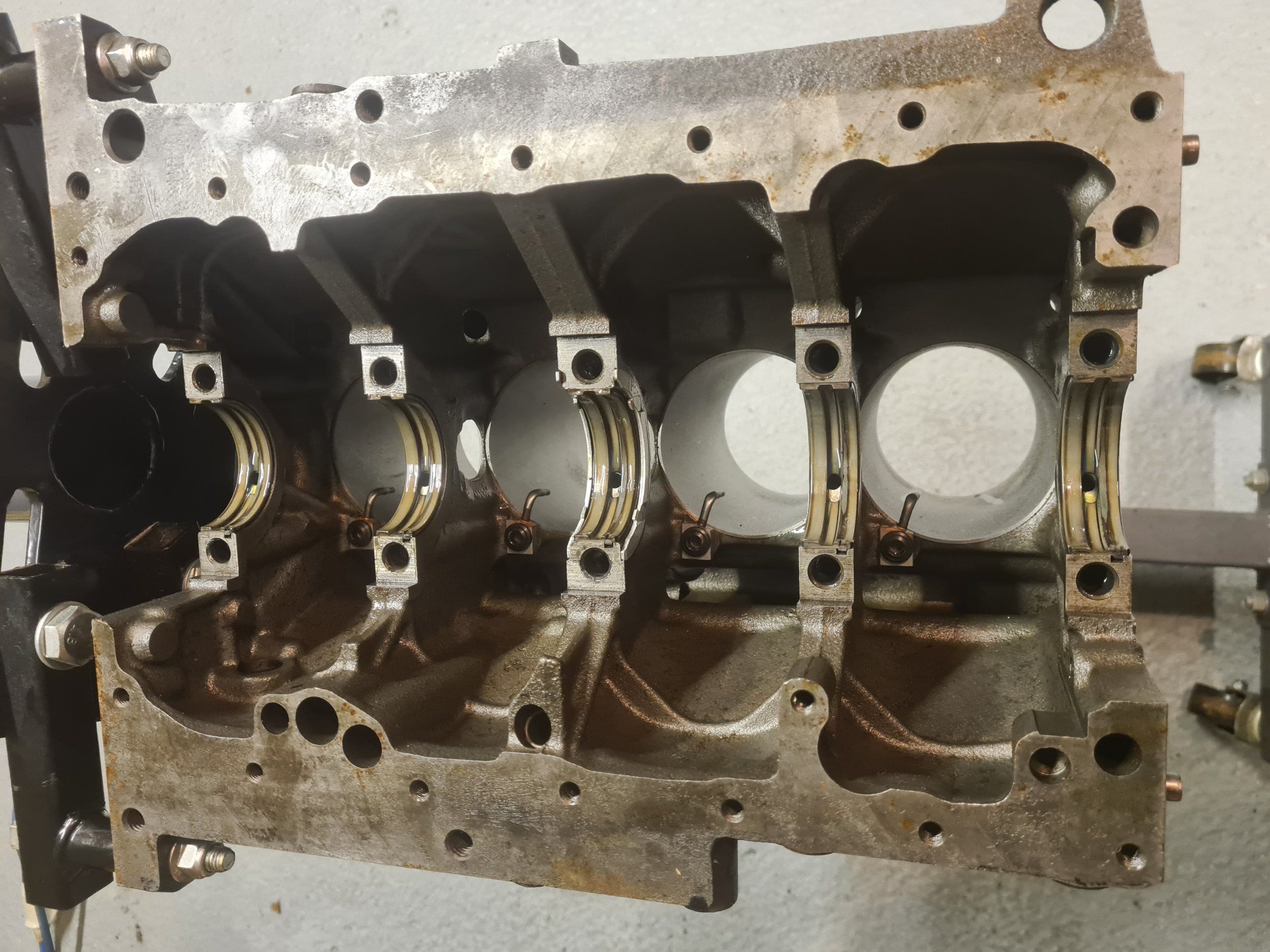

Well.. started off well. Cleaned out the block. Slid in the main end bearing. All the bearings in the block run with groves. All the smooth bearings go in the main end caps. Apart from no4 that has a groves shell.

Cleaned the crank, all the oil and grease to stop it from rusting. On the main journas

Lowered the crank in to the block, wind in the ARP main end studs, place some GREEN PLASIGAUGE on to to main end journals, then ,fit the billet main caps. Fit the nut and wind down to touch.....

bo77ox, ar5e, cun7y cr4p... can't torque the nuts down as left my torque wrench at work...

Cleaned the crank, all the oil and grease to stop it from rusting. On the main journas

Lowered the crank in to the block, wind in the ARP main end studs, place some GREEN PLASIGAUGE on to to main end journals, then ,fit the billet main caps. Fit the nut and wind down to touch.....

bo77ox, ar5e, cun7y cr4p... can't torque the nuts down as left my torque wrench at work...

Got a torque wrench from work...... and ordered 1 for home too.

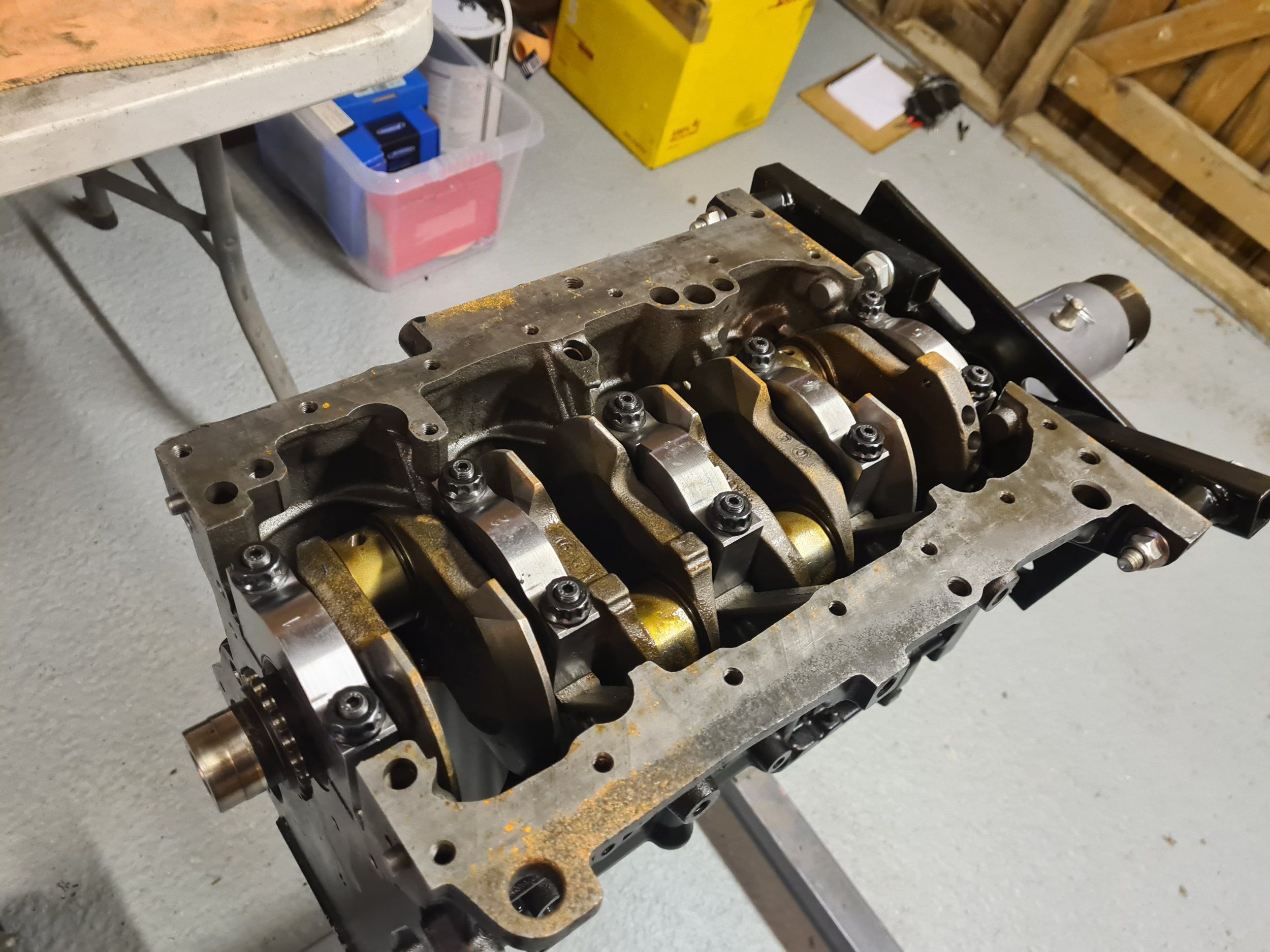

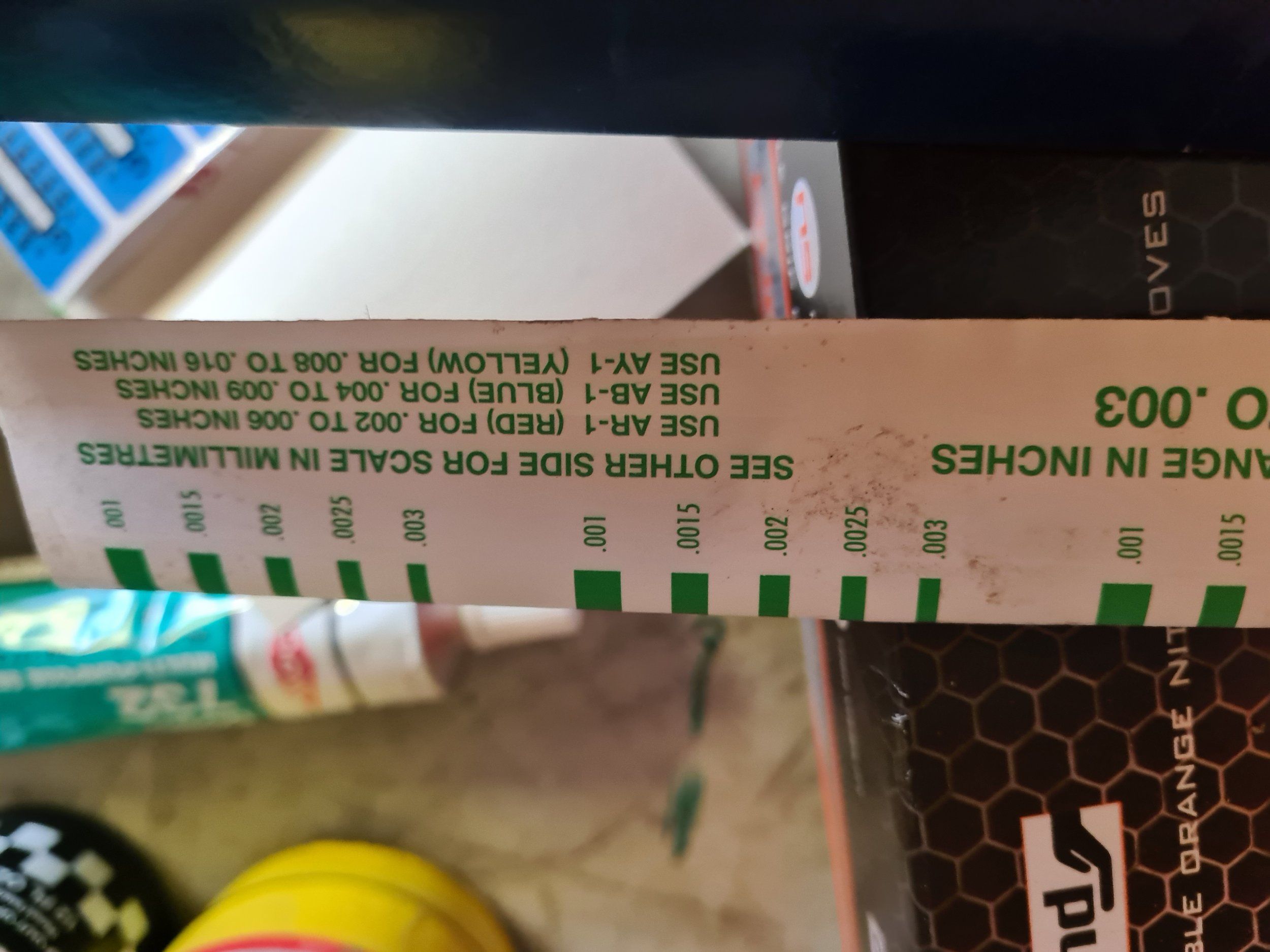

So layed some PLASIGAUGE

So layed some PLASIGAUGE

on the journals ...... then torqued the mains down

on the journals ...... then torqued the mains down

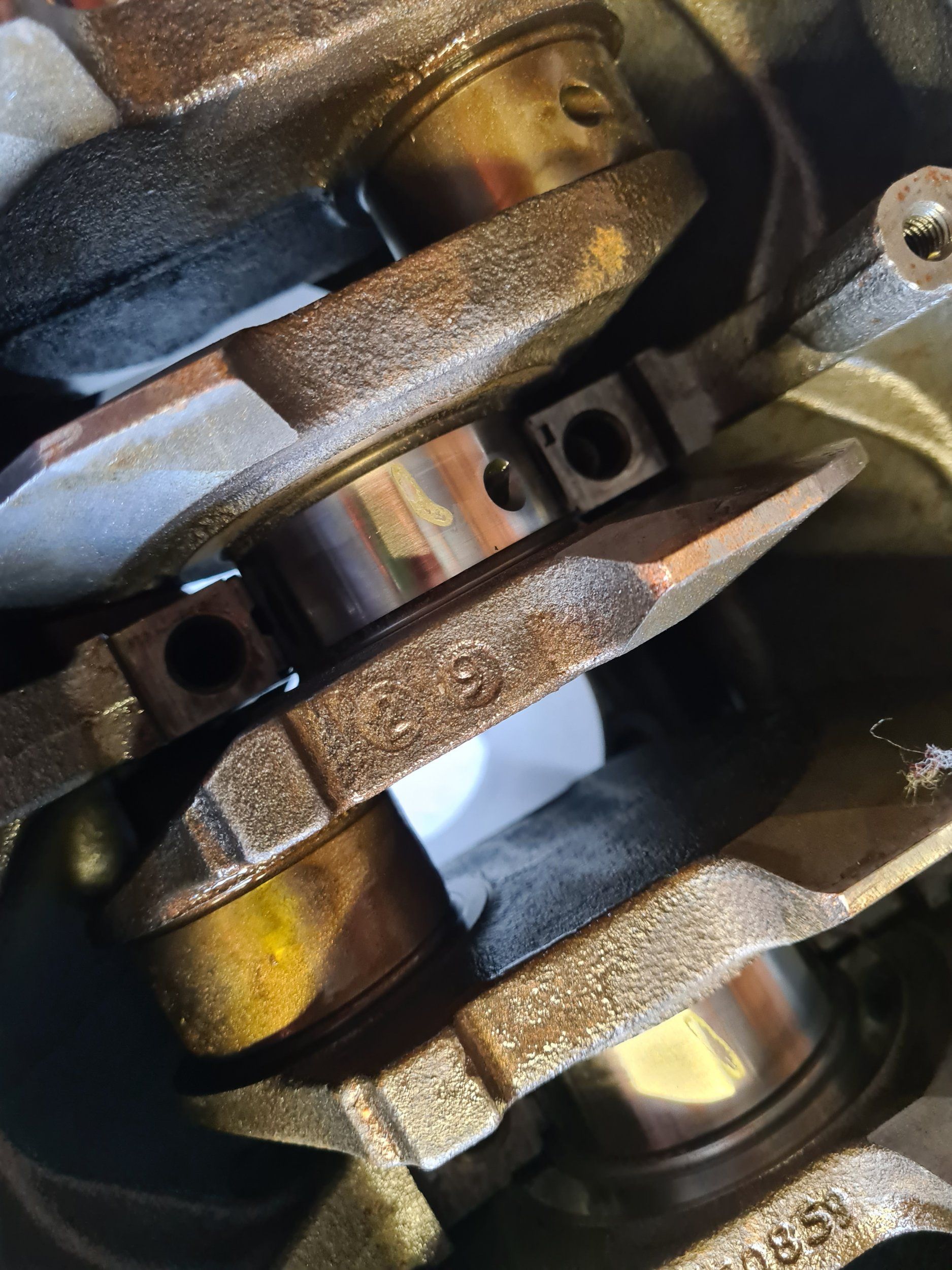

Undo the nuts and remove the studs and then main end caps

The plastigadge has squashed

leaving a mark on the crank and bearing . Using the scale on the side of the packet.

leaving a mark on the crank and bearing . Using the scale on the side of the packet.

How wide the stuff has spread shows how thick I squashed down too.

So mine are about 0.0022 though oile clearance.. they recommend. 002-.0025 tolerance. So bang in the middle

Undo the nuts and remove the studs and then main end caps

The plastigadge has squashed

How wide the stuff has spread shows how thick I squashed down too.

So mine are about 0.0022 though oile clearance.. they recommend. 002-.0025 tolerance. So bang in the middle

Last edited:

Then on to sizing piston rings. Clean the bore and lighty lubricate the bore. Using the piston upside down . Push the ring about 1.5 inch down the bore

Using feeler gauges measure the gap

Using the calculations supplied with the pistons. The top ring needs about .04 mm clearance. Basicly if the gap is too big you will loose compression. Fuel can the enter the sump, you won't get proper compression and ignition of the fuel air mix.

If too small then when the rings expand they can hit then squeeze against the wall causing extra friction and heat. That will turn in to seizing the engine.

So I purchased a ring grinder set up

Place the ring on top and give it a few turns on the wheel. Then remeasure . Your better of bit by bit and getting it right. Thats taking to much off and then having to source new rings.

So top ring has to be .04mm 2nd ring .045 and then.oil scraper .04 mm. Its very time consuming.

But keep each set marked to what bore you set them up in. So it will all be purfect.

But keep each set marked to what bore you set them up in. So it will all be purfect.

Using feeler gauges measure the gap

Using the calculations supplied with the pistons. The top ring needs about .04 mm clearance. Basicly if the gap is too big you will loose compression. Fuel can the enter the sump, you won't get proper compression and ignition of the fuel air mix.

If too small then when the rings expand they can hit then squeeze against the wall causing extra friction and heat. That will turn in to seizing the engine.

So I purchased a ring grinder set up

Place the ring on top and give it a few turns on the wheel. Then remeasure . Your better of bit by bit and getting it right. Thats taking to much off and then having to source new rings.

So top ring has to be .04mm 2nd ring .045 and then.oil scraper .04 mm. Its very time consuming.

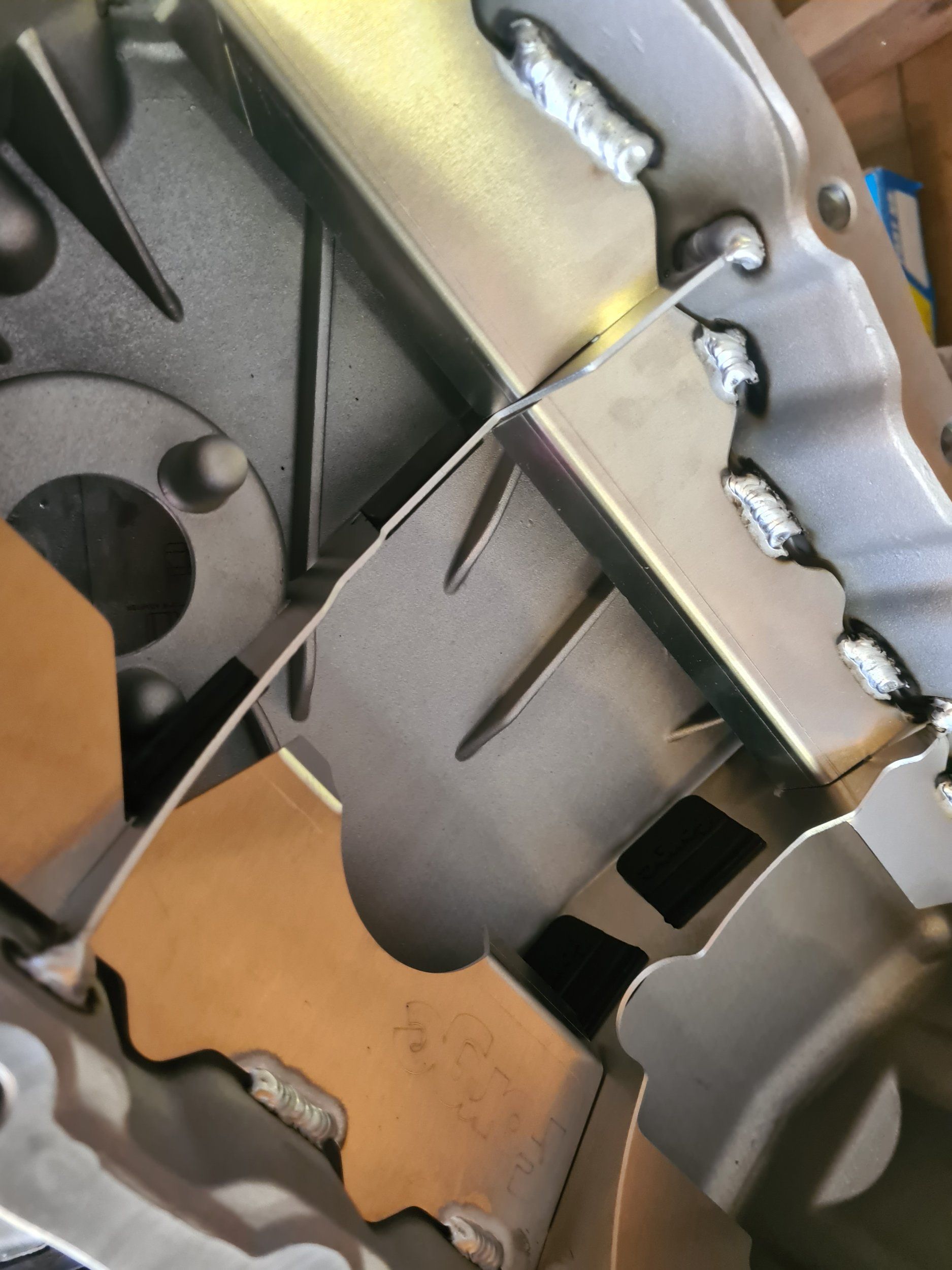

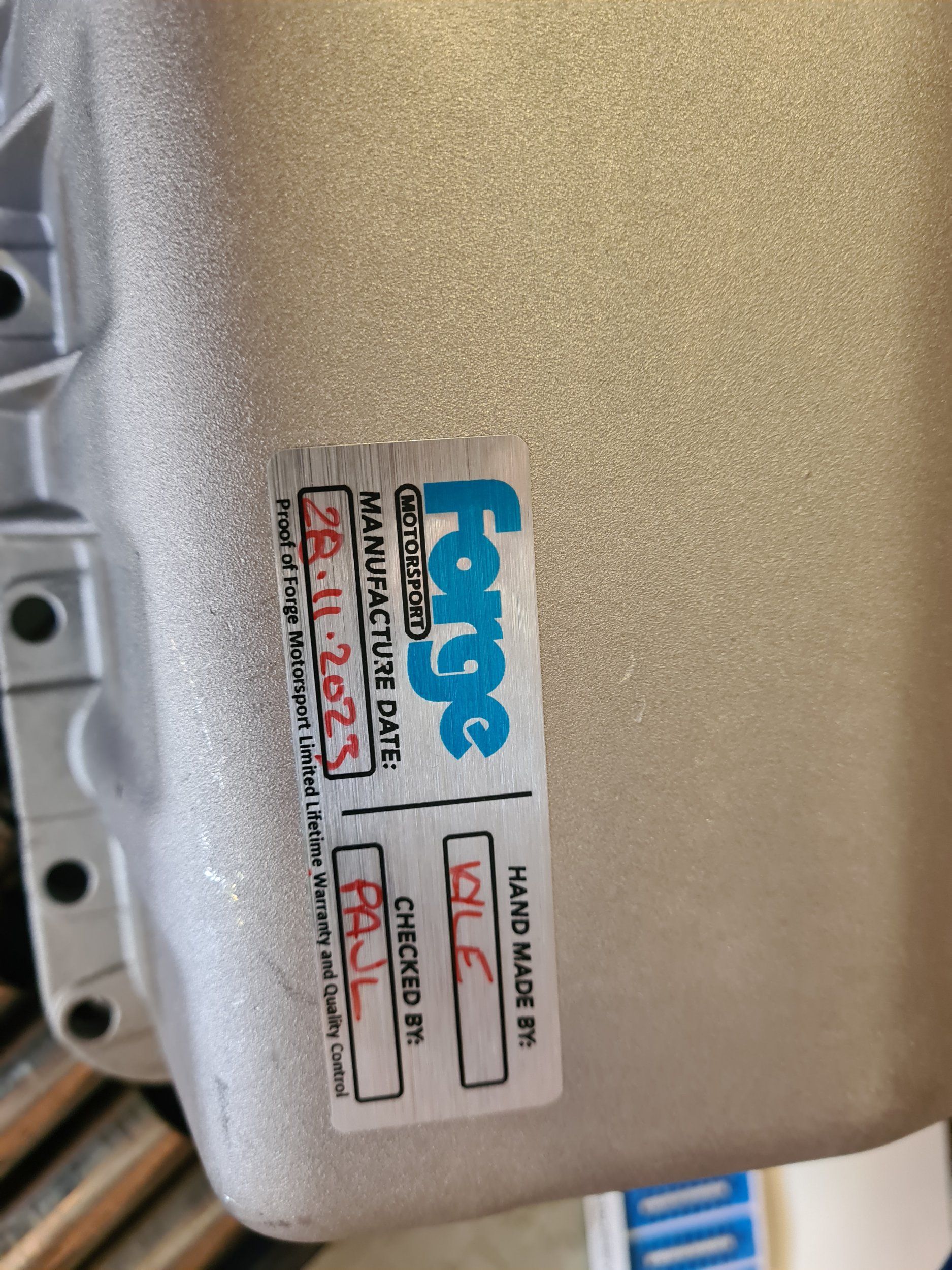

Next up..... New forge motorsport sump.

some lovely welding holding in the baffel plates.

some lovely welding holding in the baffel plates.

Even labeled up to show who made it and who checked it too

Even has the oil level sensor hole.

But I won't be using that so they even supply a forge blanking plate with stainless screws

And to be on the safe side to help monitor the heat threw the engine. I have some stick on temp gauges. They only work and stay at the max temp they went to.

And to be on the safe side to help monitor the heat threw the engine. I have some stick on temp gauges. They only work and stay at the max temp they went to.

So if it goes bang I can see how hot different areas of the engine got

Even labeled up to show who made it and who checked it too

Even has the oil level sensor hole.

But I won't be using that so they even supply a forge blanking plate with stainless screws

So if it goes bang I can see how hot different areas of the engine got

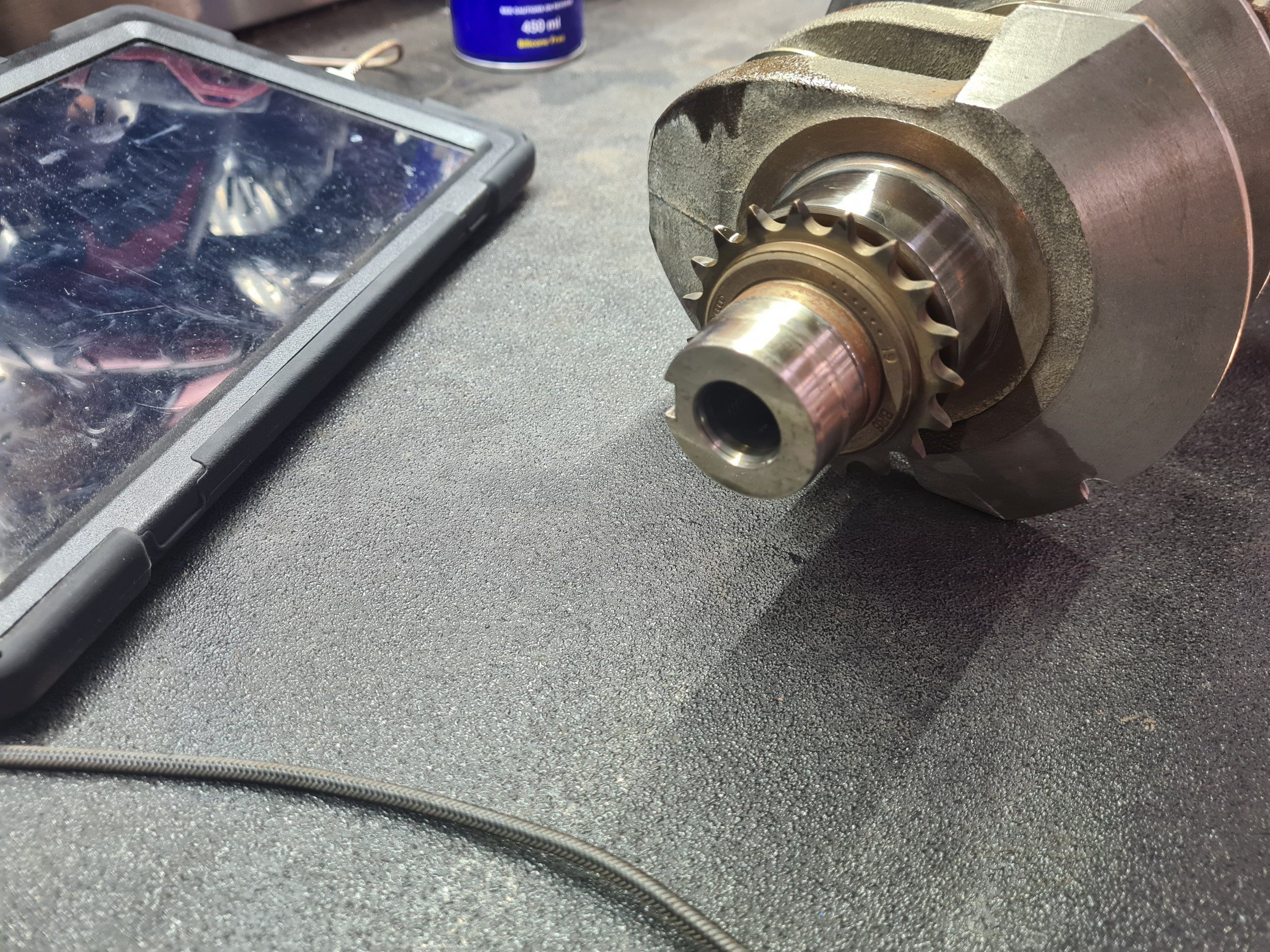

Need to change the oil pump gear on the crank. As I am going to be using a 2.0TFSi crank. The tfsi is different to the 1.8t gear

the TFSI (totally F ing stupid idea) gear is smaller. So using a small puller I put a bolt in the end of the crank for some where for the puller to press against

the TFSI (totally F ing stupid idea) gear is smaller. So using a small puller I put a bolt in the end of the crank for some where for the puller to press against

Then with a little heat from the oxyaccetalyne gun and the milwaukee 1/2 gun

Then with a little heat from the oxyaccetalyne gun and the milwaukee 1/2 gun

the old one came off.

the old one came off.

With the new gear in the oven waming up to expand it . I cleaned the crank shaft. I then held it in a vice with cloths in the gaws to not damage the crank. The new gear slipped over the top. With a large socket I held it down till it called and contracted

All done and cleaned

So then gave all the oil wats a blow threw with the air gun. Then coated it in oil and wrapped it up and in a plastic bag to bring it home

With the new gear in the oven waming up to expand it . I cleaned the crank shaft. I then held it in a vice with cloths in the gaws to not damage the crank. The new gear slipped over the top. With a large socket I held it down till it called and contracted

All done and cleaned

So then gave all the oil wats a blow threw with the air gun. Then coated it in oil and wrapped it up and in a plastic bag to bring it home

Bugger. I thought I had written some thing but I hadn't. I would like to say a massive thank you to. https://decimaltenths.co.uk/

A lot of the information ,ideas,specs and even down to the tolerances to run in side the engine has come from thier youtube videos. Starting with this one.

If your going to build a stroker, even just curious about it , or just love watching people build stuff to a high spec and tolerances with how it is done. I can highly recommend to watch thier channel. Thanks again decimal tenths

A lot of the information ,ideas,specs and even down to the tolerances to run in side the engine has come from thier youtube videos. Starting with this one.

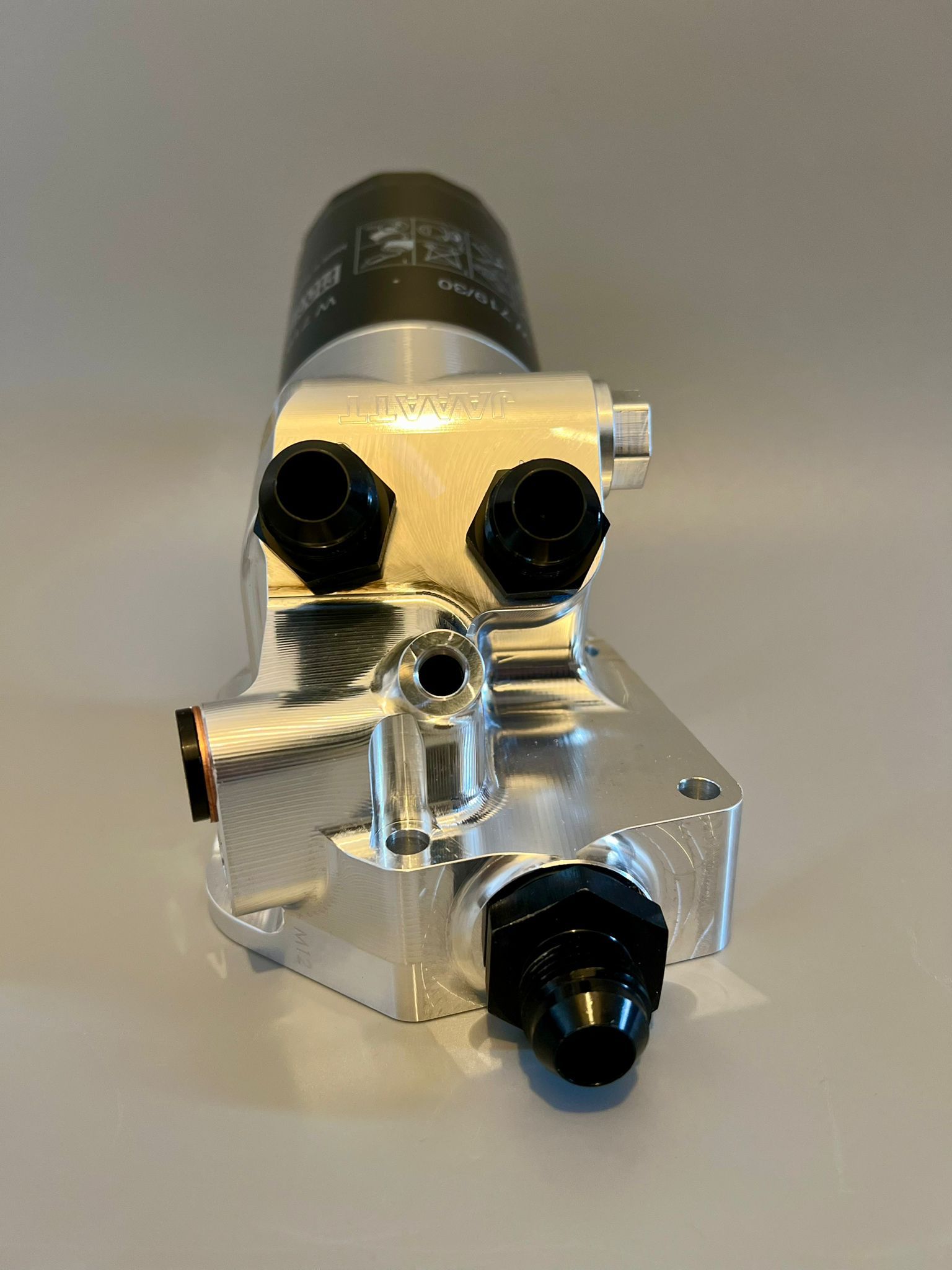

TOP SECRET.... I have been asked not to share these. But they too good not to show .

Drum roll....... I am having billet oil filter housing made. With extra ports for oil cooler . So no need for the sandwich plate. Should be finalised in next couple of months fingers crossed

This is lovely machineing. . Love the finish on this... I will post more details when I have it in my hands

Drum roll....... I am having billet oil filter housing made. With extra ports for oil cooler . So no need for the sandwich plate. Should be finalised in next couple of months fingers crossed

This is lovely machineing. . Love the finish on this... I will post more details when I have it in my hands

I need, I want, must have...TOP SECRET.... I have been asked not to share these. But they too good not to show .

Drum roll....... I am having billet oil filter housing made. With extra ports for oil cooler . So no need for the sandwich plate. Should be finalised in next couple of months fingers crossed View attachment 40508 View attachment 40509

This is lovely machineing. . Love the finish on this... I will post more details when I have it in my hands

Ooo...so shinyTOP SECRET.... I have been asked not to share these. But they too good not to show .

Drum roll....... I am having billet oil filter housing made. With extra ports for oil cooler . So no need for the sandwich plate. Should be finalised in next couple of months fingers crossed View attachment 40508 View attachment 40509

This is lovely machineing. . Love the finish on this... I will post more details when I have it in my hands

Gonna be such an awesome MK1. I've got track car envy

It's not massively common that they are being made. He asked me last year not to say any thing. This is why I didn't put his name or company.No secret... designed and manufactured by Junior(JAATT)

Will be great when he finally releases them to the public!

https://jaaattengineering.co.uk/onl...ing-18t-20v-billet-oil-filter-housing-for-06a they have gone up for sale today

Some pics of the finished item...

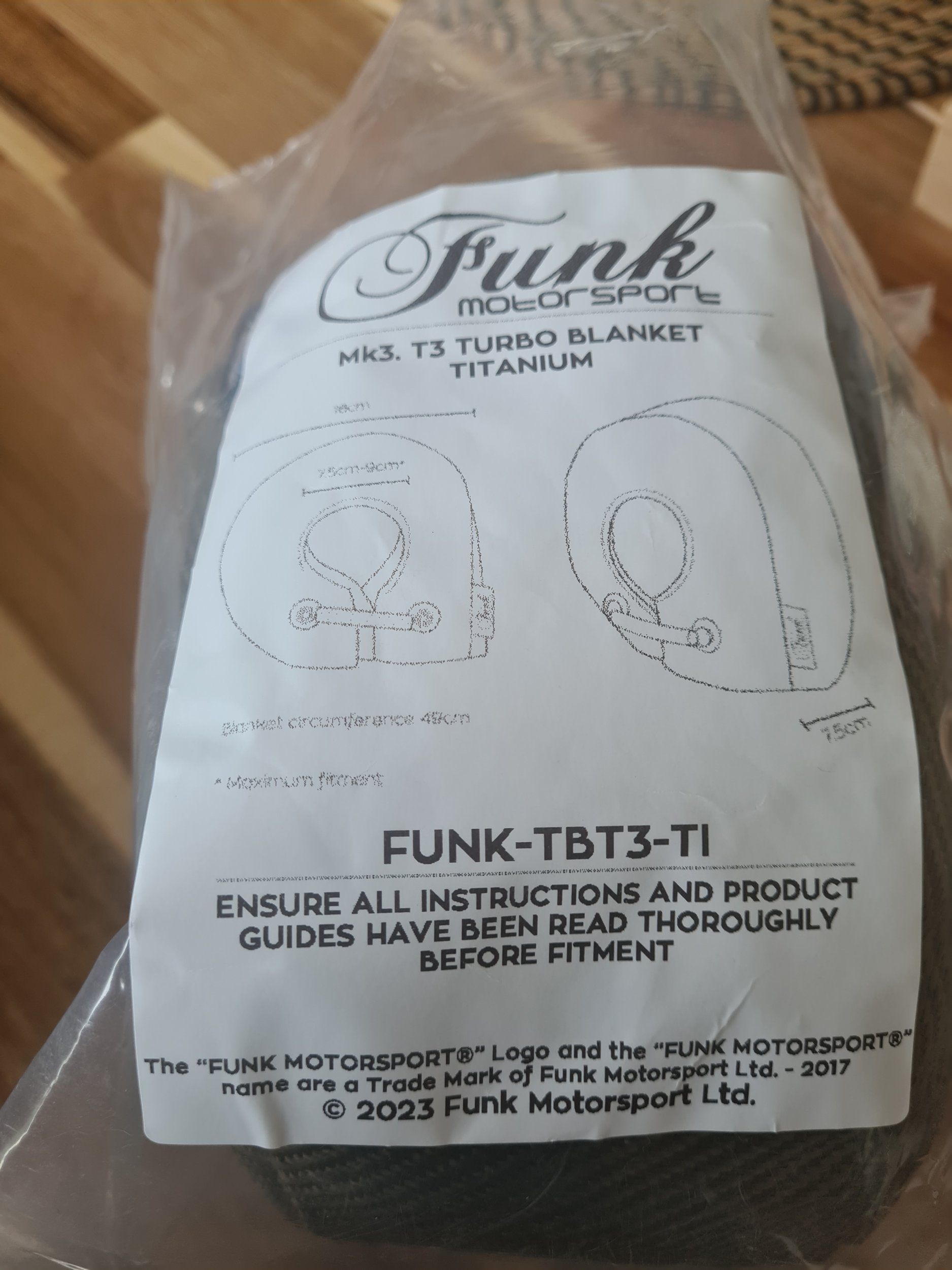

Mr postman came today..... Nice bit of heat management from funk motorsport.

The idea is to keep the heat in the turbo and exhaust system and not in the engine bay. Keep the engine cool.

So to stat with... a baby little blanket for the waste gate

These are hand made . I went for the titanium finish. Ad much as I love carbon fibre. I think the titainium finish will have a nicer look under the bonnet. Then we have the bigger blanket for the hot side of the turbo

All are multilayer insulated and with a fine wire mesh around the edge keeping the blanket all together. And they sell off the shelf. For all applications .

The idea is to keep the heat in the turbo and exhaust system and not in the engine bay. Keep the engine cool.

So to stat with... a baby little blanket for the waste gate

These are hand made . I went for the titanium finish. Ad much as I love carbon fibre. I think the titainium finish will have a nicer look under the bonnet. Then we have the bigger blanket for the hot side of the turbo

All are multilayer insulated and with a fine wire mesh around the edge keeping the blanket all together. And they sell off the shelf. For all applications .

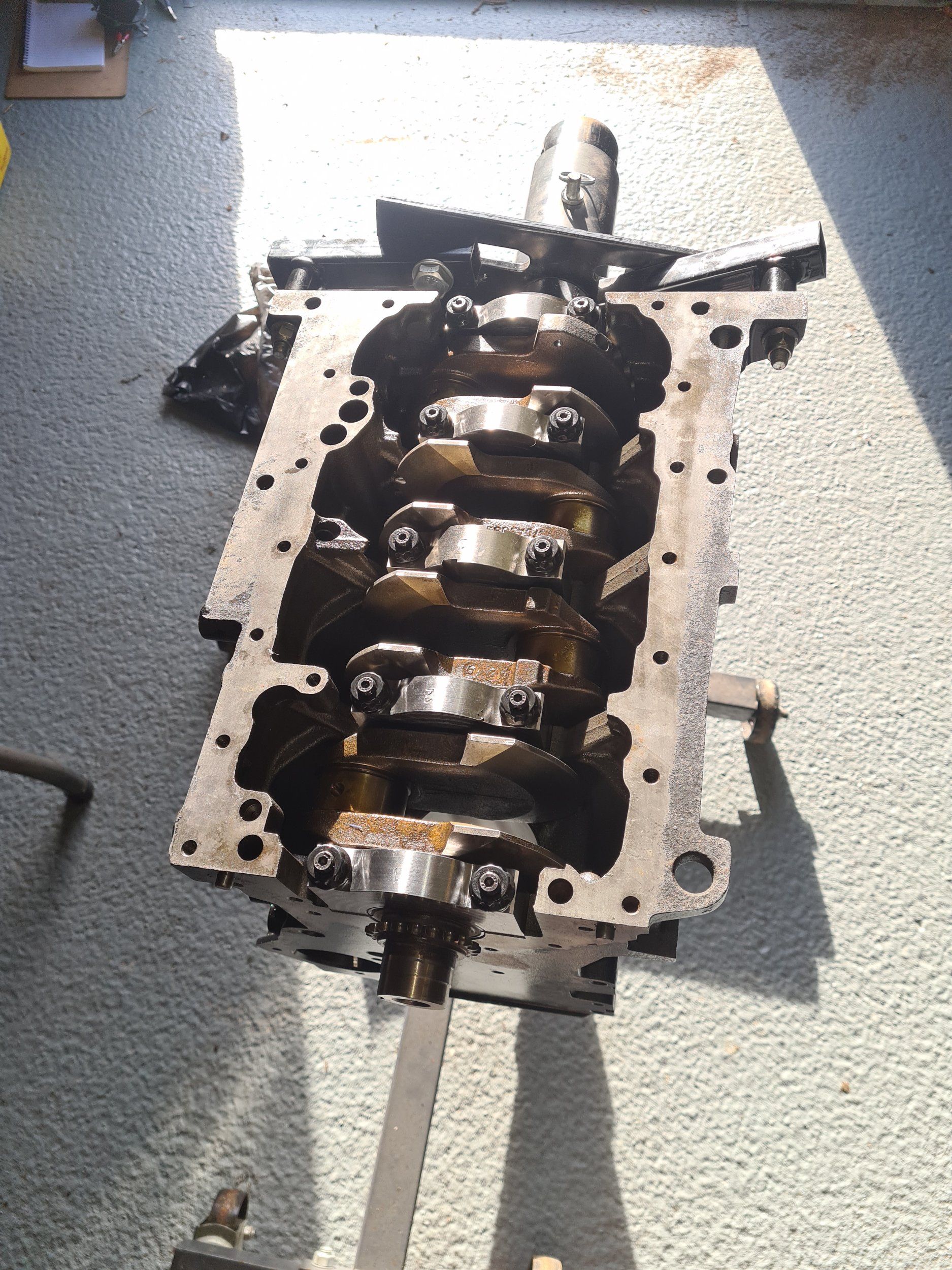

As most good times start with lube....

Clean and cleaned the block and refitted the main end capthen a covering of the lucks assembly lube. This stuff is like thick gearbox oil and stringy

Then after having fitted the new oil pump drive gear

I have also changed the timing pick ring.

Using new screws and a little loctite. .now ready

Using new screws and a little loctite. .now ready

gently lower the crank in to position and spin over

gently lower the crank in to position and spin over

screw in the arp main end studs. Clean the billet caps and fit the AVL race bearing . Slide on and seat the caps over the crank then tighten threw steps. 20lbs,40lbs then 60lbs

screw in the arp main end studs. Clean the billet caps and fit the AVL race bearing . Slide on and seat the caps over the crank then tighten threw steps. 20lbs,40lbs then 60lbs

Just line up the high flow oil pump

Clean and cleaned the block and refitted the main end capthen a covering of the lucks assembly lube. This stuff is like thick gearbox oil and stringy

Then after having fitted the new oil pump drive gear

I have also changed the timing pick ring.

Just line up the high flow oil pump

Similar threads

- Replies

- 0

- Views

- 887

- Replies

- 0

- Views

- 483

- Replies

- 22

- Views

- 1K