Finished work for Christmas at 2.00pm today so took the chance to spend a couple of hours over the workshop to see if the machining work done on the manifold has done the job...

The manifold... provisioning for wastegate...

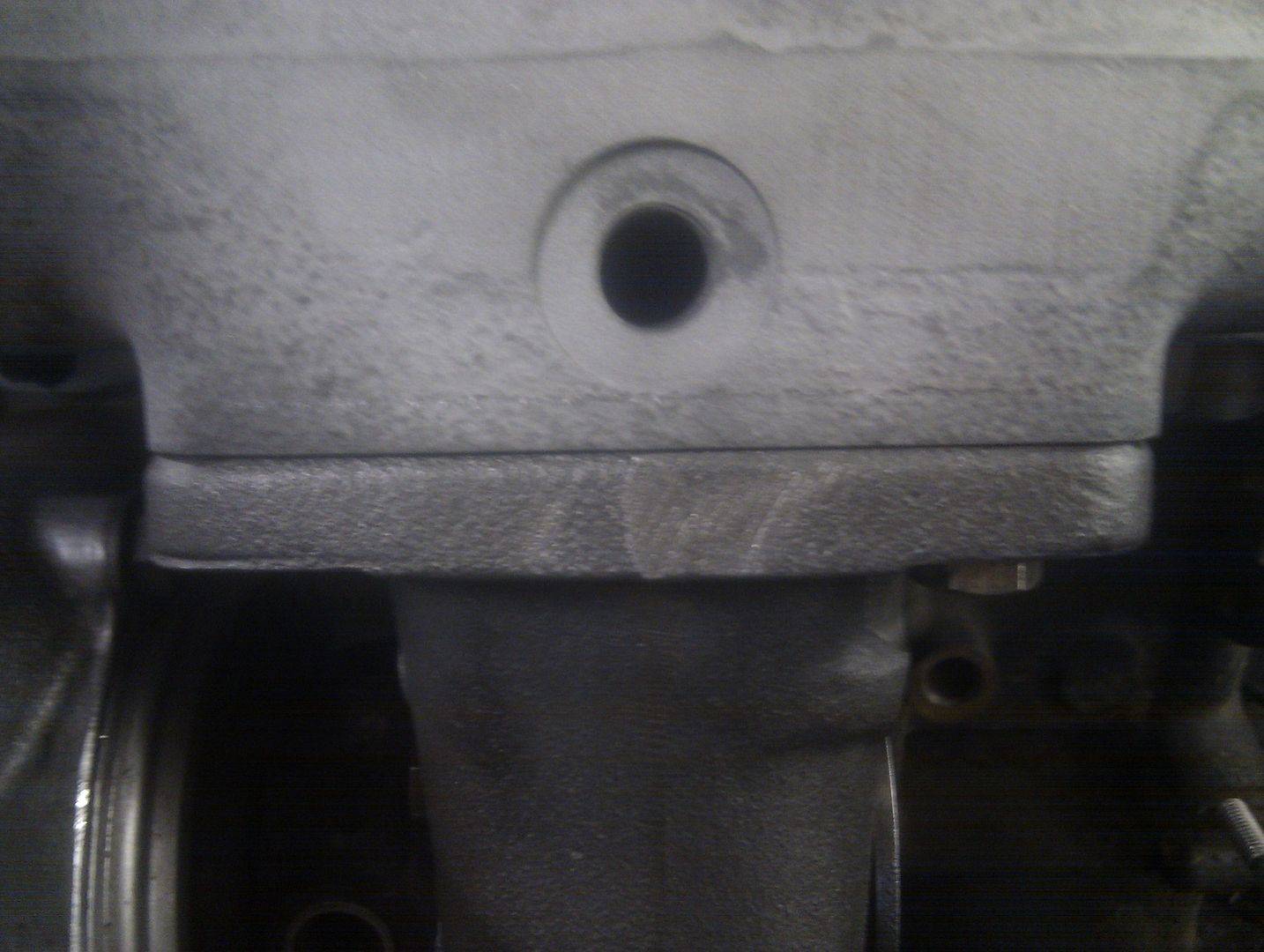

5mm machined from turbo mounting face and holes enlarged from M8 to M10

...obviously this has highlighted the crack I have which has been caused in fairness to the manifold by the stainless steel plug for the EGT probe hole I had put in...

...this carries on inside a bit to but Bill will weld these with his special rods so no drama... the TIAL wastegate will fit like this...

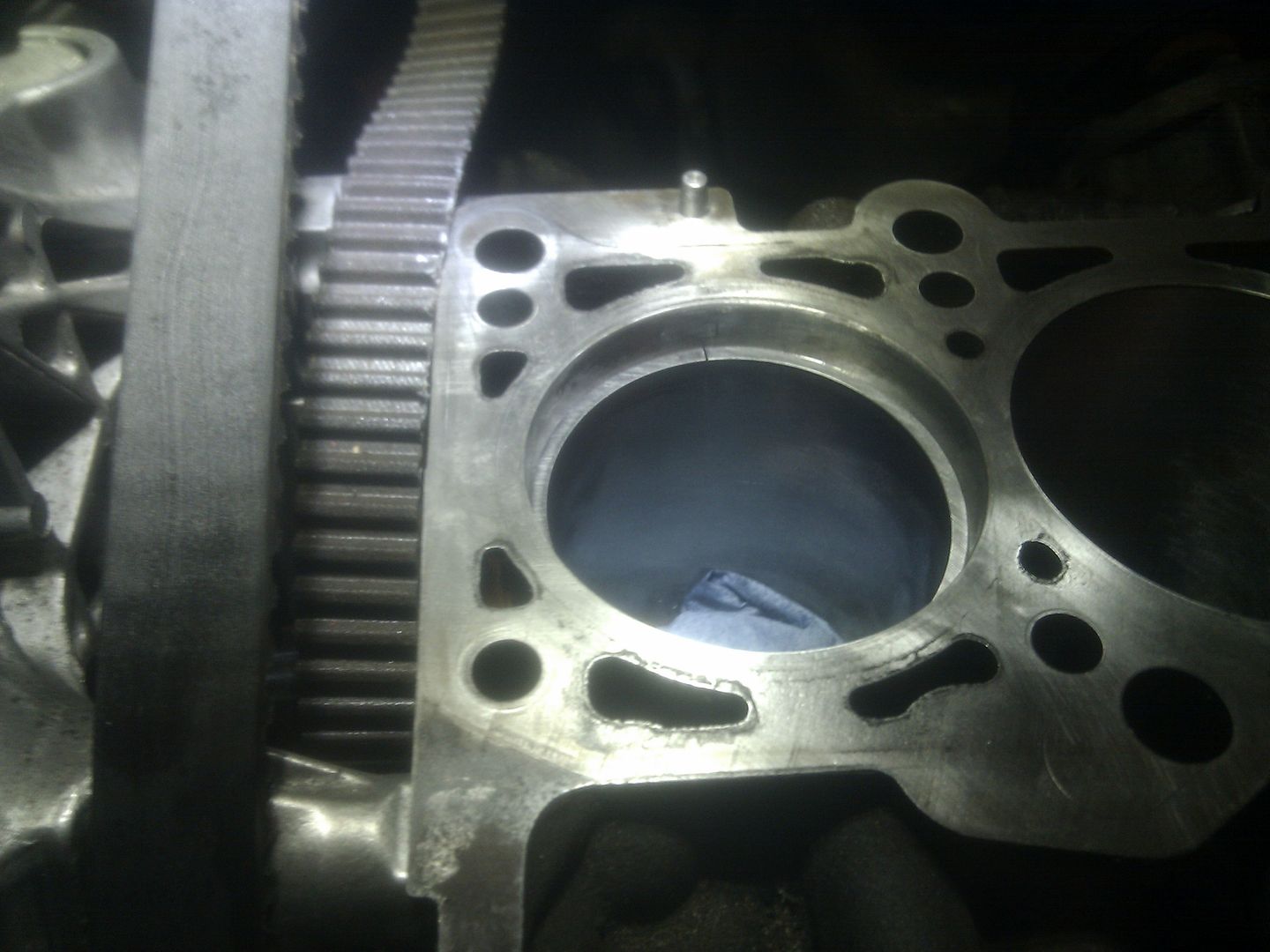

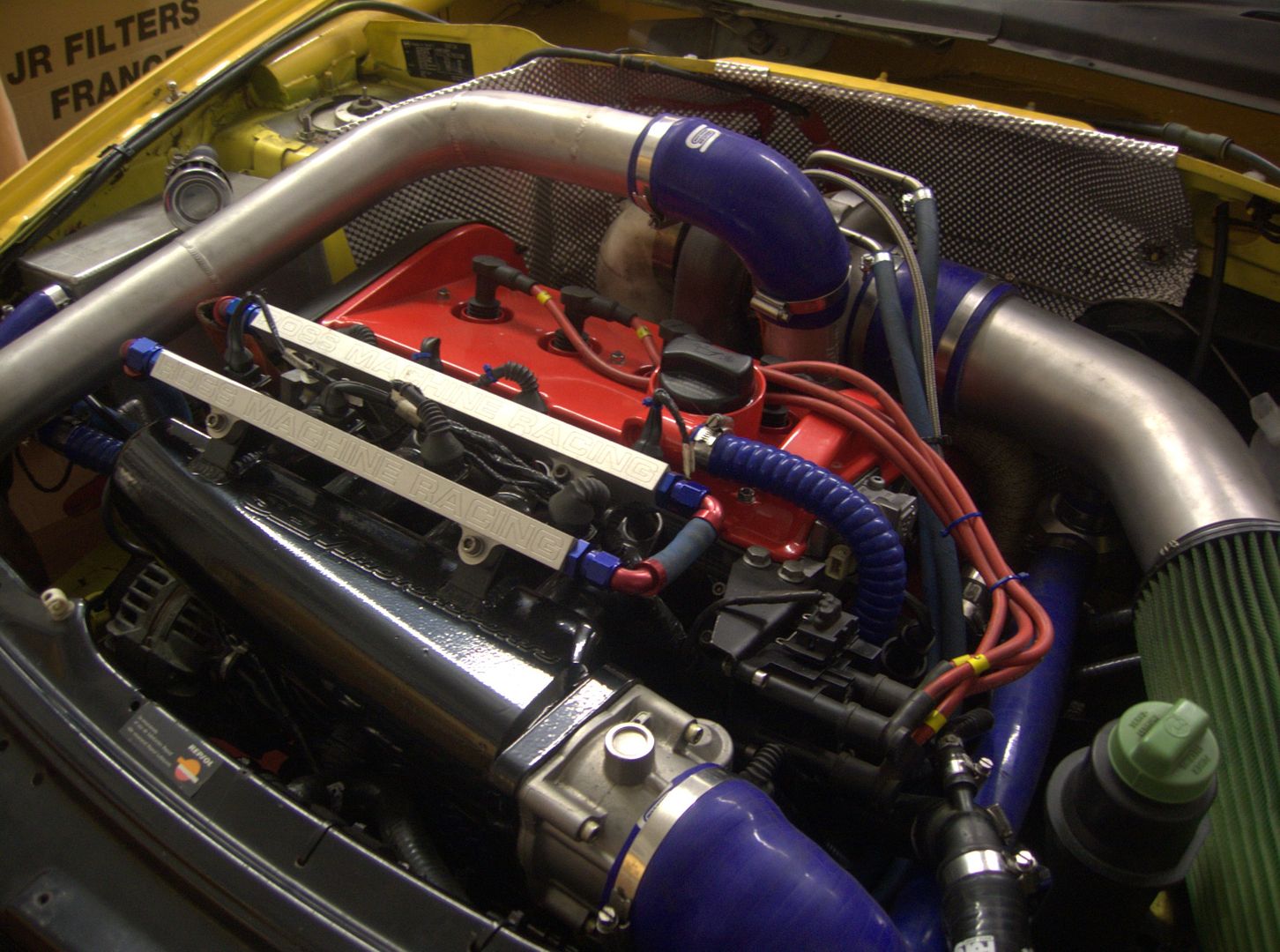

So... all good so far... I already knew about the crack and we have a plan to deal with that so next job was to bolt it all too the head and offer it onto the engine to see if I now had the clearance I needed... first

problem due to the 5mm of material removed from the flange was that the comp housing hit the nut/stud and wouldn't sit in the turbine housing square... booo!!!

..so a bit of fettling and repositioning of the manifold and that now clears... phew!!... next I dropped the head with the turbo fitted onto the engine... for the life of me it would not sit on the dowels on the back of the block!!!... clearly it was hitting something on the back of the block which wasn't obvious before... took the head off and plonked it on to a scrap block we have lying about for engine mock ups and bingo... the comp housing was hitting an unused bolt fixing on the back of the block!!...

So out came the grinder and that 'issue' was no more... I used the old headgasket and a couple of the old head bolts to bolt down the head and bingo... everything now clears... still tight but a result non the less...

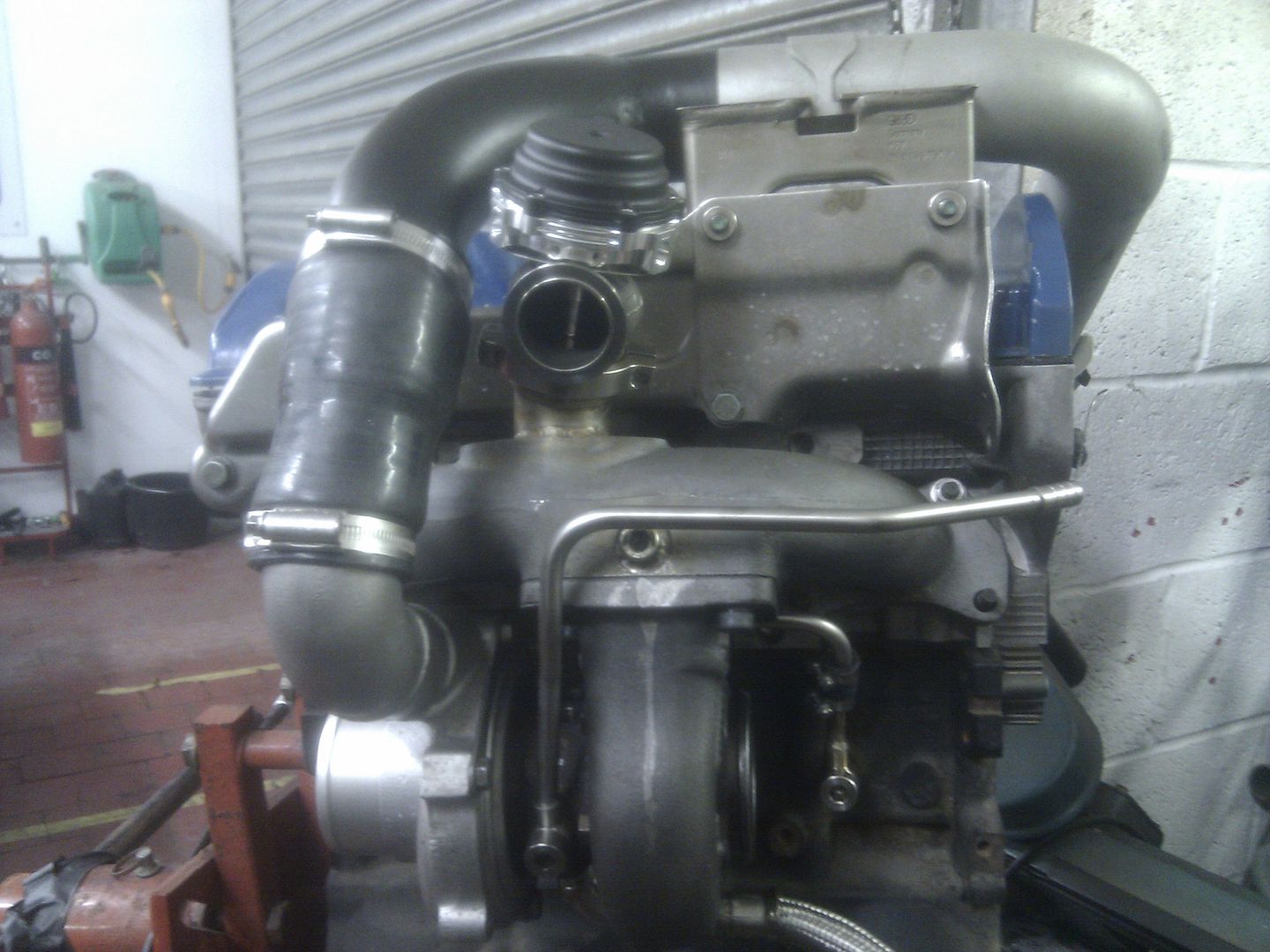

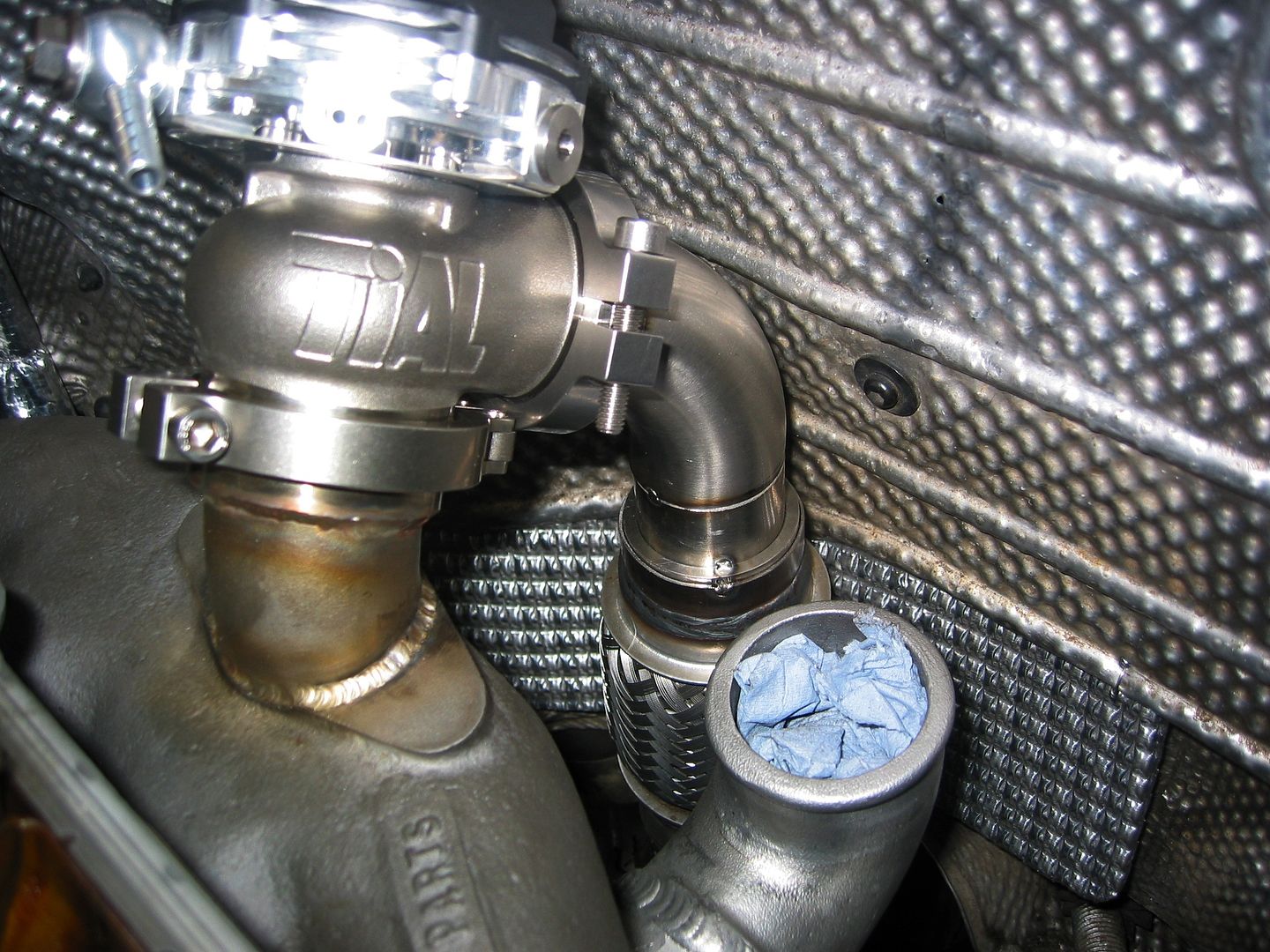

Tried the TIAL to see what clearance we have there too...

Fantastic... turbo fits... well happy with that... of course the next

problem is the oil drain and the water pipe to the block... the old oil drain went under the bottom of the hotside but the T3 one is bigger so thats not gonna happen and the water pipe I currently have is no longer in the right position now the turbo has moved over a bit... I have to try and squeeze it between to block and the turbo somehow and I think some modding of the bevel box bracket may

help here but thats tomorrows challenge

Plenty left to do but at least I know the turbo now fits and the challenges left as relatively straight forward engineering and fabrication ones...

Big thanks to Nigel for turning the manifold around so quick and of course a massive thanks to Bill for just about everything really...

More tomorrow...

<tuffty/>