You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nice project, lots of nice parts made.... Hat's off to you.

I also have a 8374 but with the .92 a/r housing, they do look the part don't they

What manifold are you planning on using or are you building your own ?

Much respect,

Graham.

I also have a 8374 but with the .92 a/r housing, they do look the part don't they

What manifold are you planning on using or are you building your own ?

Much respect,

Graham.

Nice project, lots of nice parts made.... Hat's off to you.

I also have a 8374 but with the .92 a/r housing, they do look the part don't they

What manifold are you planning on using or are you building your own ?

Much respect,

Graham.

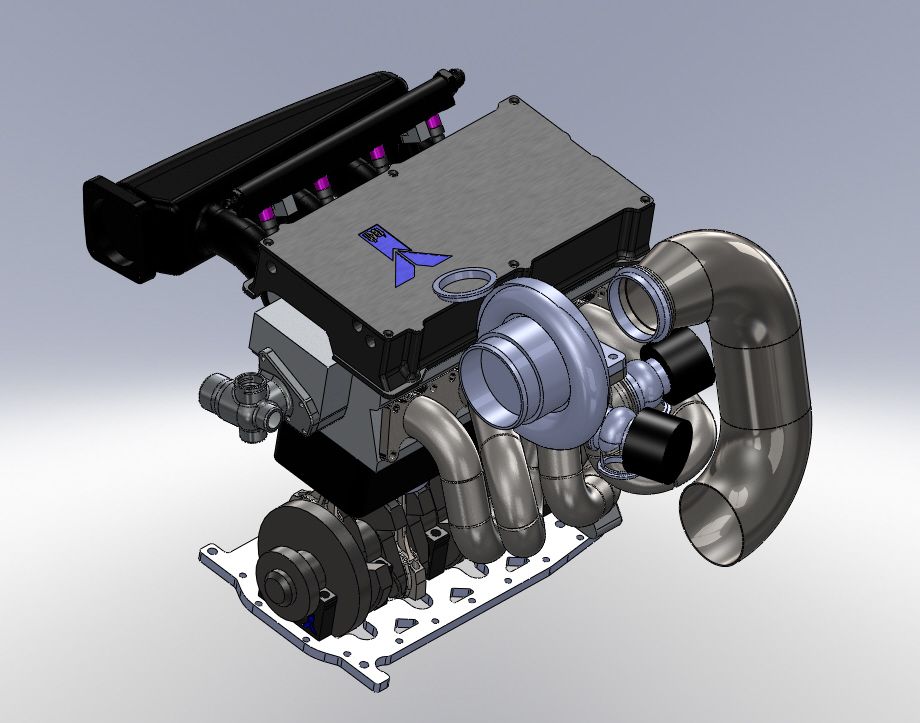

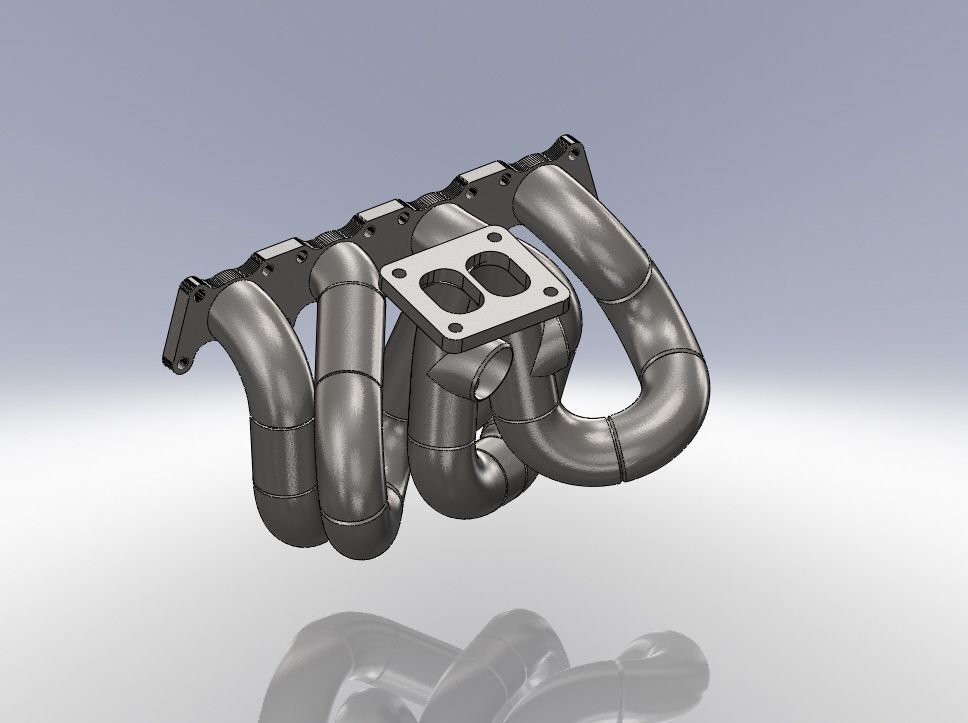

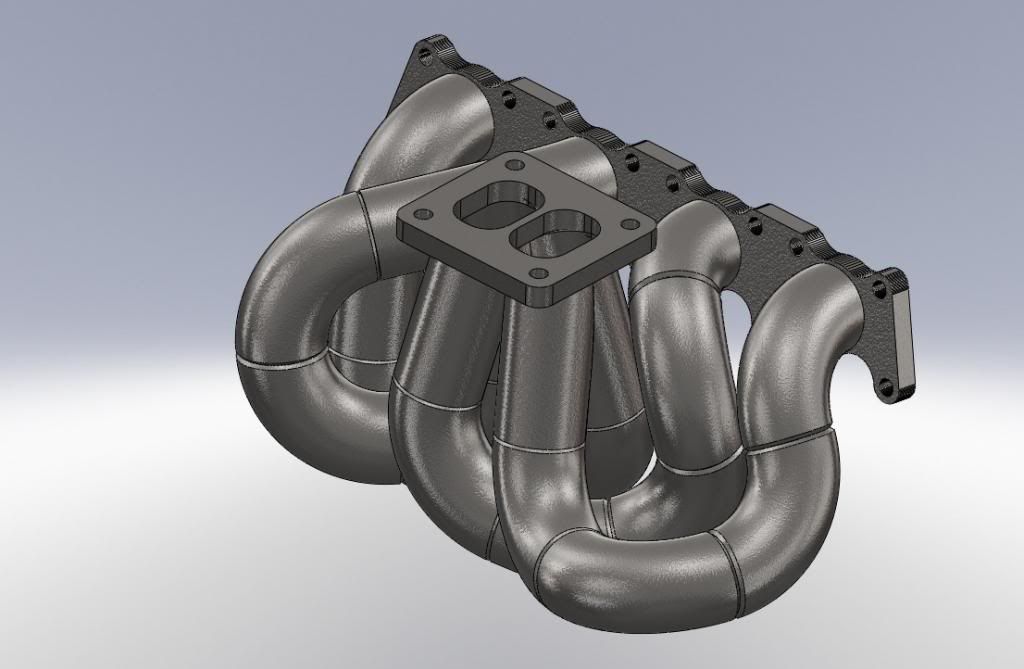

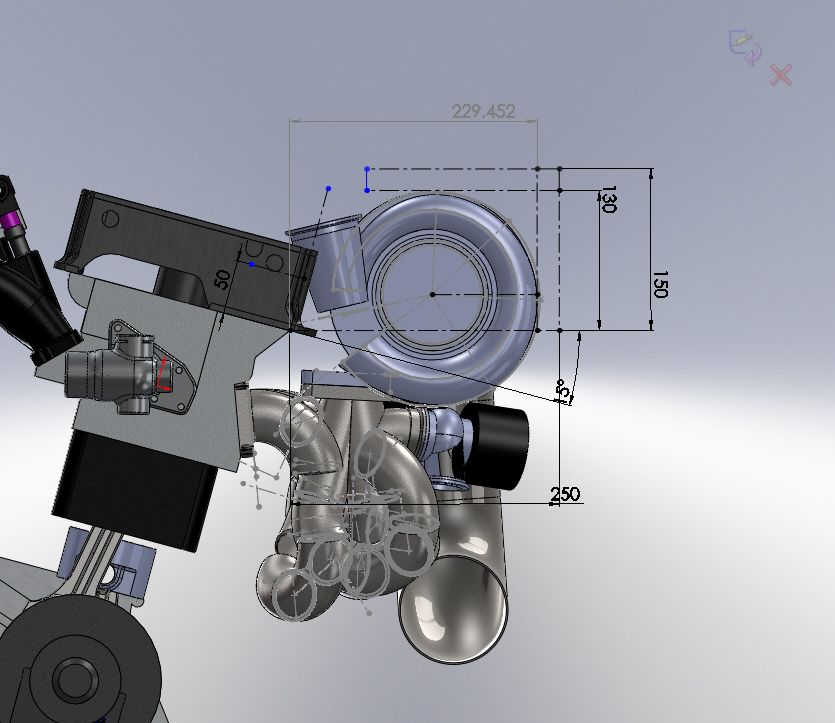

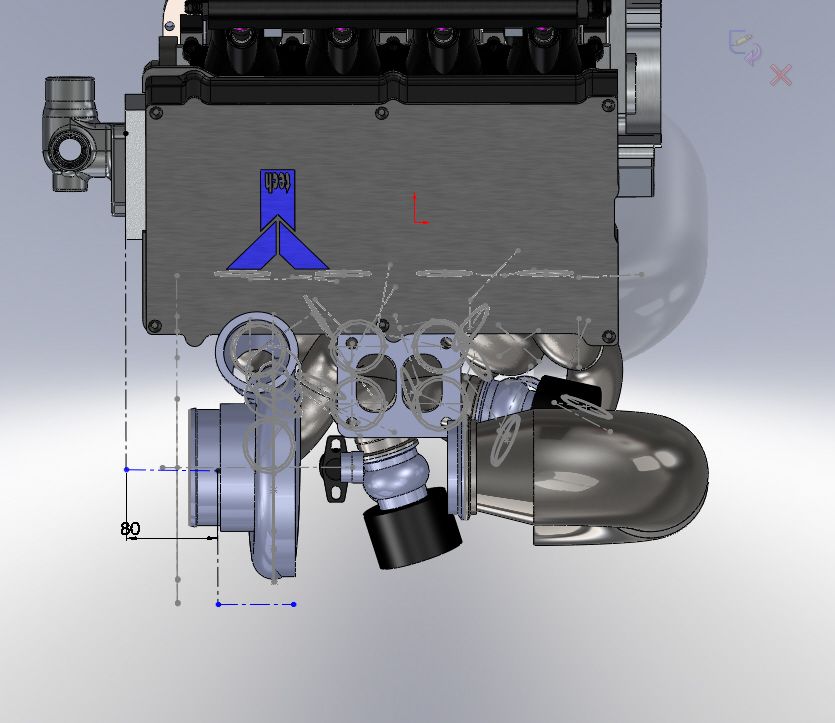

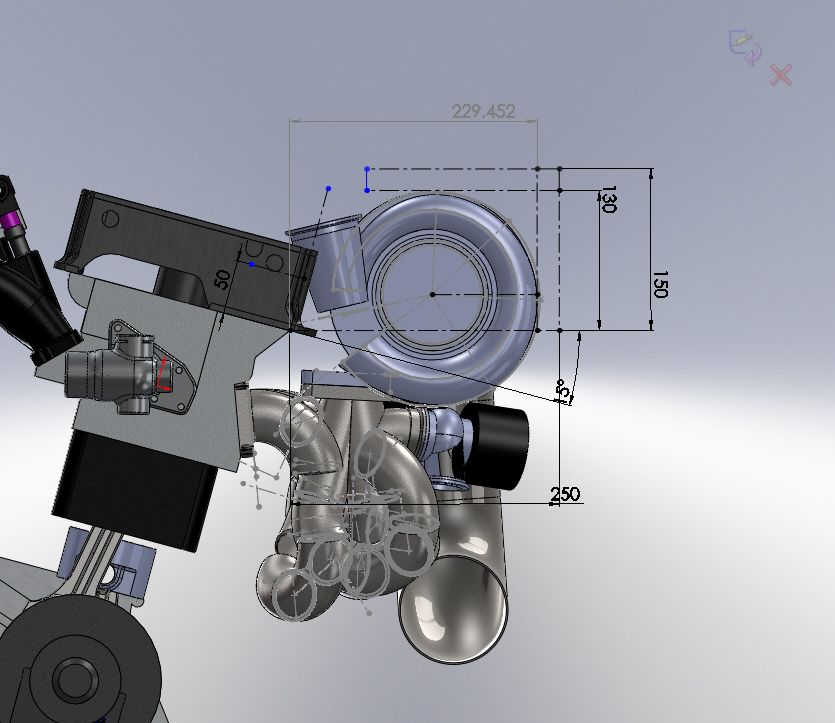

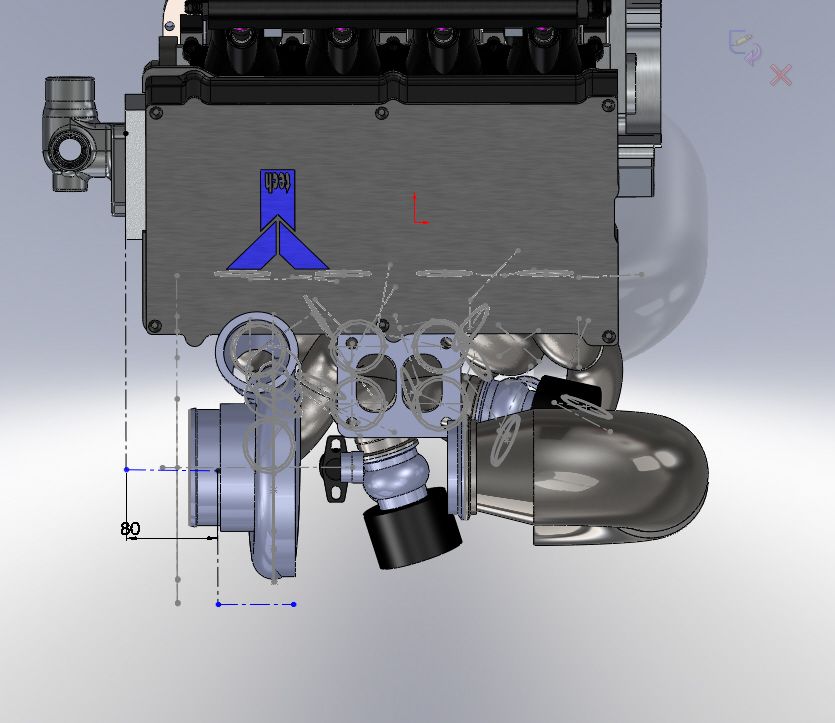

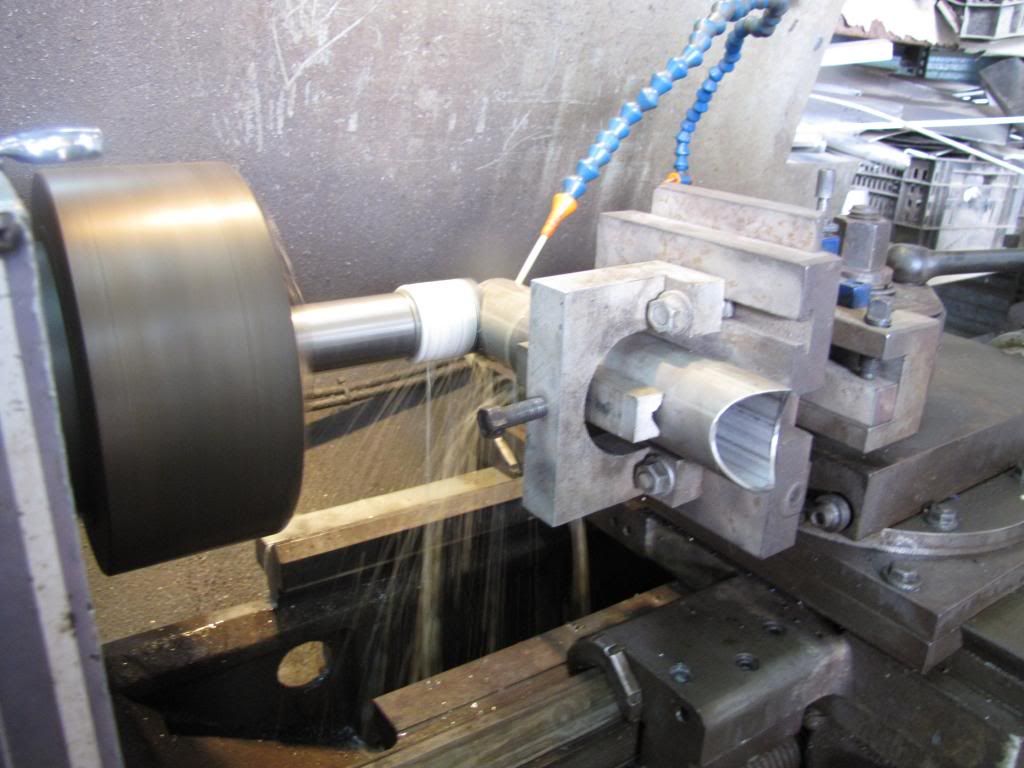

Thanks, yes I'm planning on using my own manifold, I sketched it up on SW to verify all of the clearances where ok and make the runners equal in length.

actually all that is left to do is put a mock up motor together with a trany and make a brace for the flange and start building it I orderd some SCH 10, 304 SS elbows I should be picking up tomorrow.

Looks like a nice design, have you tried to fit the turbo in between the engine and the bulkhead ????? i tried mine in and the compressor housing was really tight to fit, it could be fitted but it was really tight.

I'll be watching this build with much interest

I'll be watching this build with much interest

Last edited:

was just looking at you're build you have an awesome! project going on there much of the same things I am doing

I have not tried to fit it yet, I am going to try and fit it in on the week end and see but according to my measurements I should have at the least about 10mm between the turbo and the fire wall with the turbo at the position I have it in at the moment, I can still bring it forward a bit.

do you remember how much clearance you had ? you have any pictures that would be great help

Thanks

I have not tried to fit it yet, I am going to try and fit it in on the week end and see but according to my measurements I should have at the least about 10mm between the turbo and the fire wall with the turbo at the position I have it in at the moment, I can still bring it forward a bit.

do you remember how much clearance you had ? you have any pictures that would be great help

Thanks

Thanks, i didn't have a great amount of room. i didn't measure it i simply took the compressor housing off and then tried it behind the engine. It will go but will probably need the brake pipes rerouting and maybe a bit of bulkhead / firewall massaging

I don't have any pics, sorry.

I don't have any pics, sorry.

ok thanks

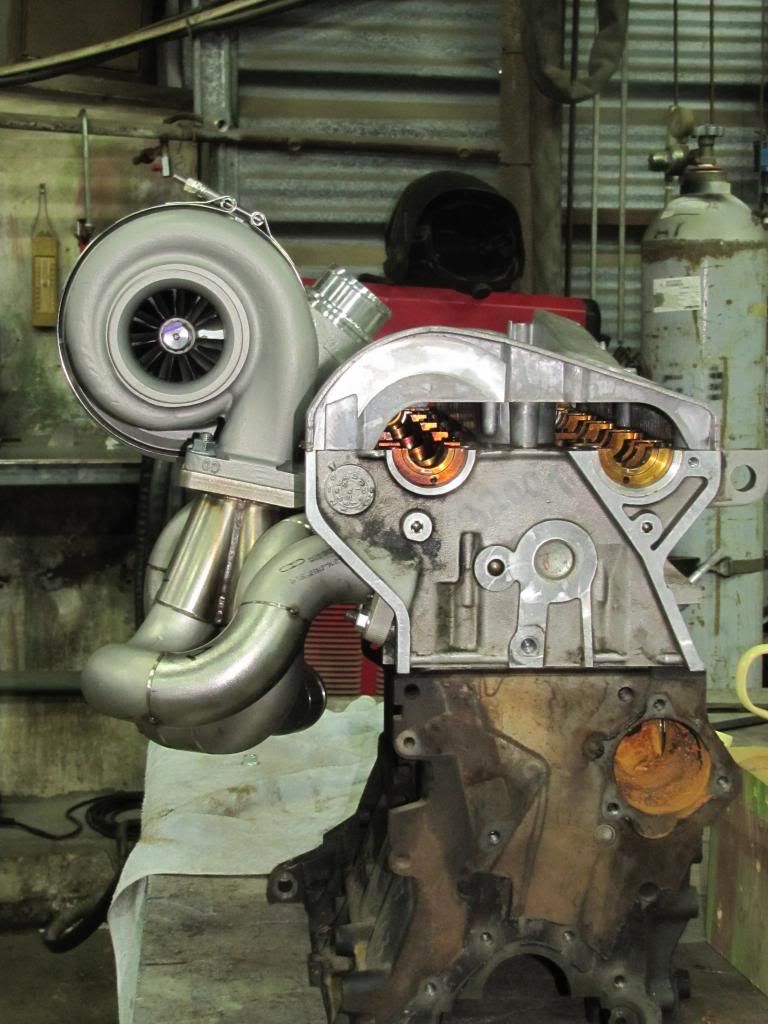

I measured everything up and remeasured a few times to make sure all my measurements are correct because it is a bit hard to measure the space accurately and according to my sketch I have enough room for the turbo with sufficient space between it and the fire wall enclosure

I also positioned the turbo in relation to a cylinder head I have for muck up to make sure the position of the flange is correct and it looks good to go. just not sure about the internal bypass valve it looks like its getting in the way of the valve cover a bit, but nothing i cant work out.

got some parts in before the weekend, a set of inconel cold rolled turbo studs with a set of stage 8 nuts and lockers to make sure the turbo stays connected with a proper seal under high boost.

also received the Innovate wide band and a few fab parts.

I should start working on the exhaust manifold next week now that i have all the parts in

I measured everything up and remeasured a few times to make sure all my measurements are correct because it is a bit hard to measure the space accurately and according to my sketch I have enough room for the turbo with sufficient space between it and the fire wall enclosure

I also positioned the turbo in relation to a cylinder head I have for muck up to make sure the position of the flange is correct and it looks good to go. just not sure about the internal bypass valve it looks like its getting in the way of the valve cover a bit, but nothing i cant work out.

got some parts in before the weekend, a set of inconel cold rolled turbo studs with a set of stage 8 nuts and lockers to make sure the turbo stays connected with a proper seal under high boost.

also received the Innovate wide band and a few fab parts.

I should start working on the exhaust manifold next week now that i have all the parts in

Amazing build Talx. I'm in love with the TIGART full exhaust hehe

Keep working and posting

yes he used to do awesome work, it's a pity he closed the shop and is now in business selling real estate

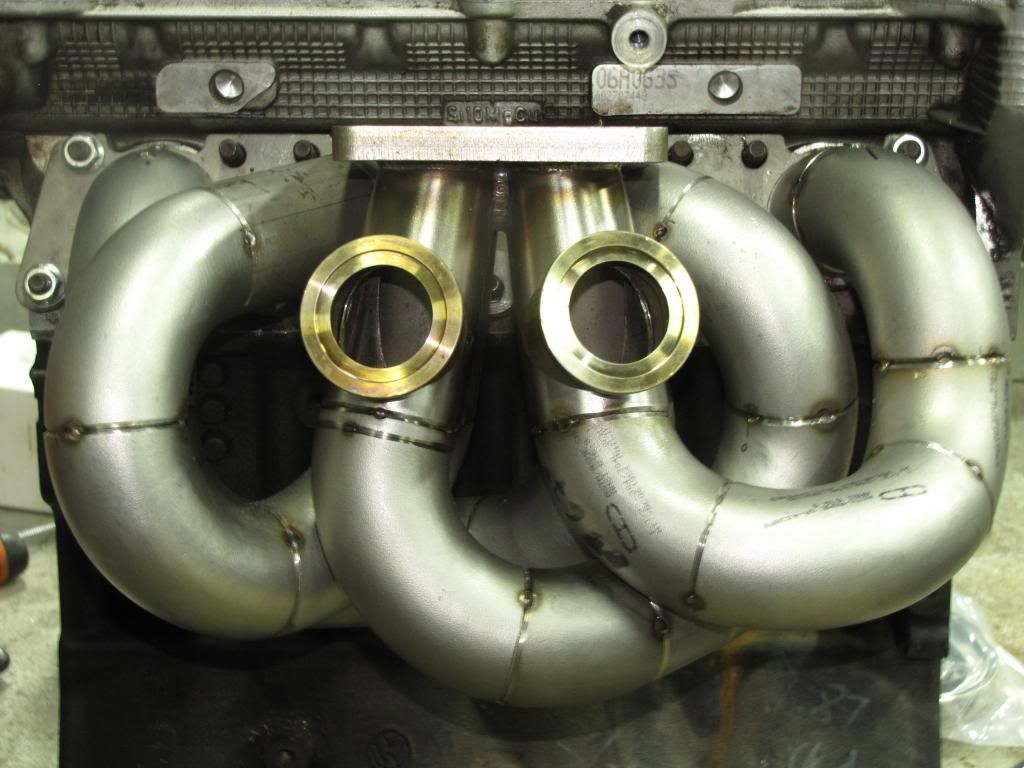

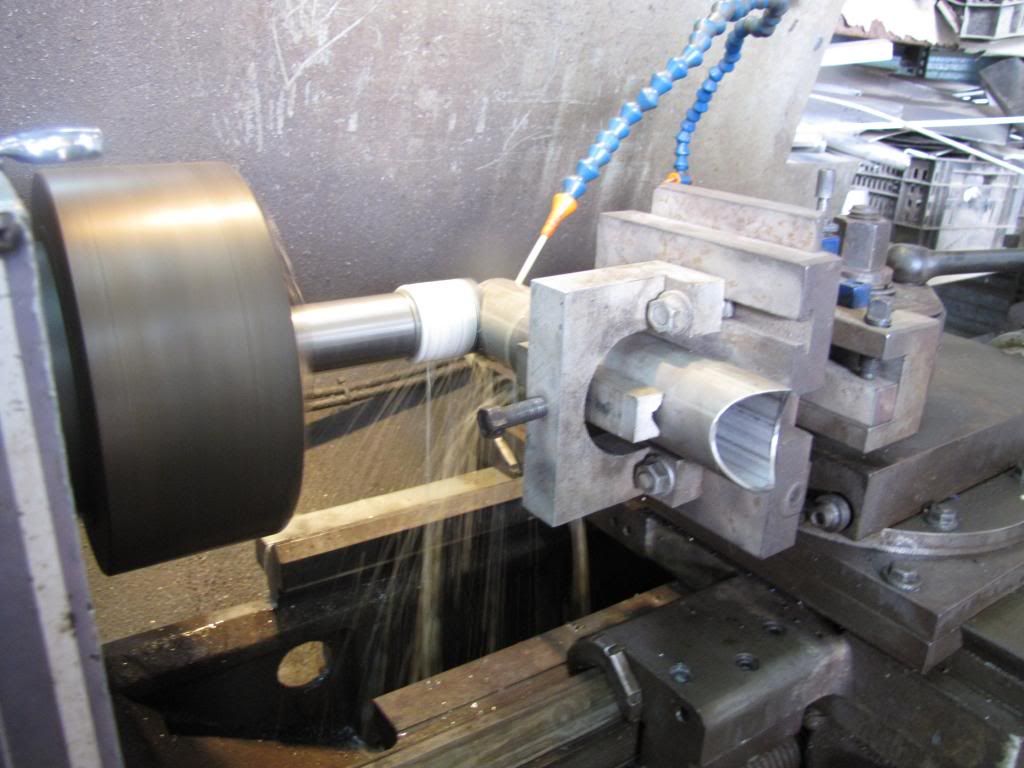

most of the time was spent on correctly positioning the Turbo flange according to the sketch ,second half of the day we finished cutting the collector pipes and welding the first lair of welding bid without a rod, but before we noticed the day was over so it's going to need to wait until next week when I have more time of

some pics from the day for now

some pics from the day for now

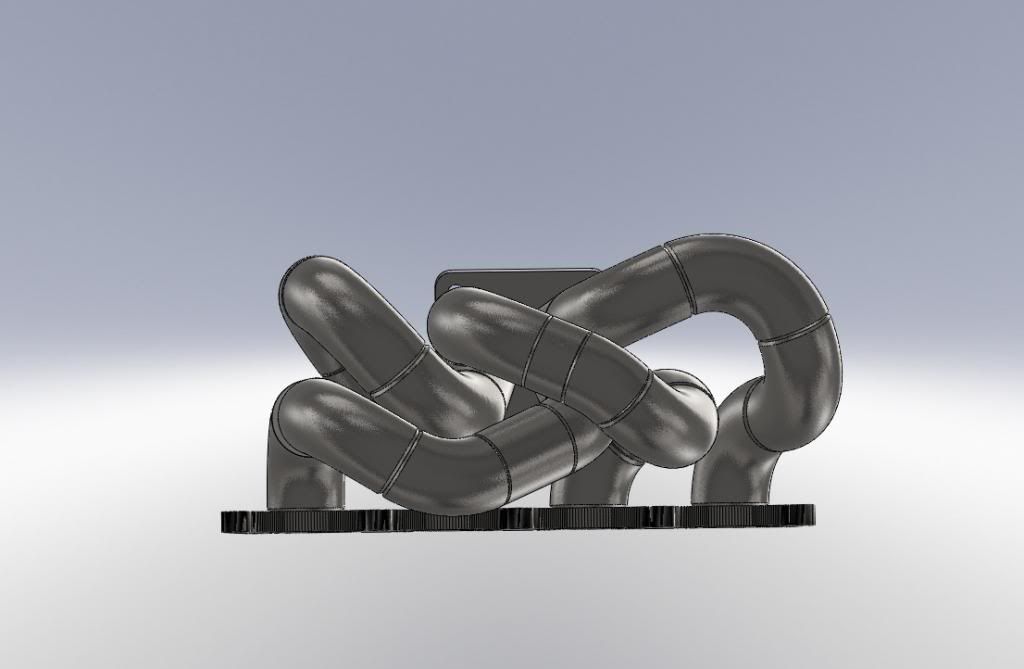

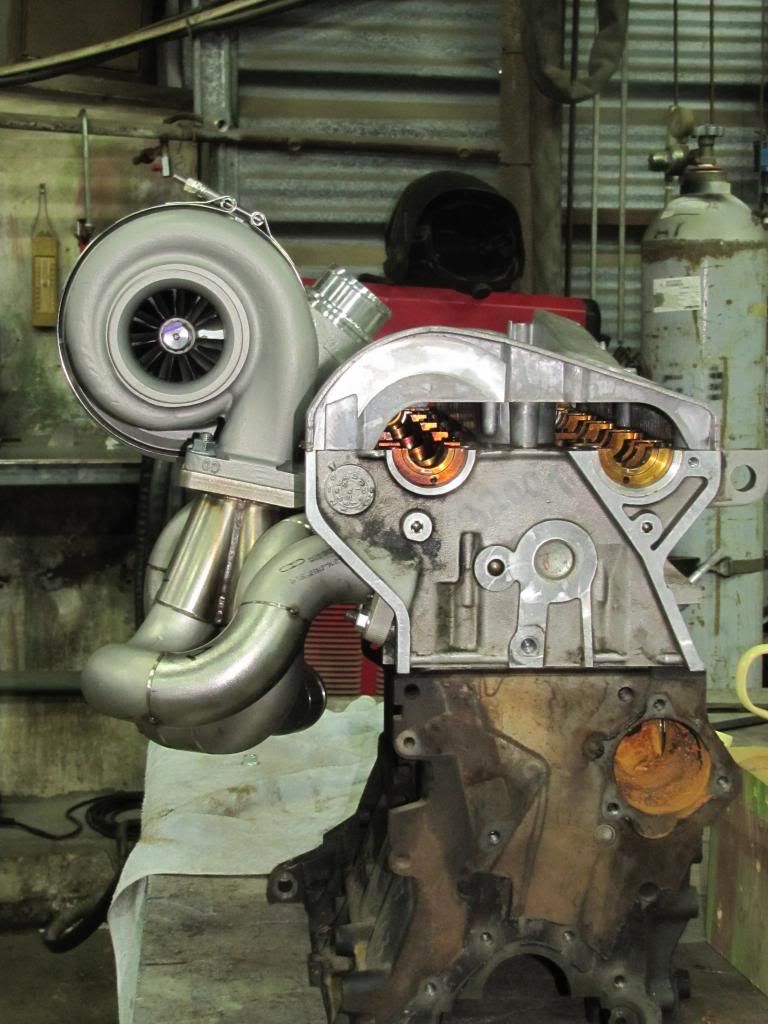

Started work on the turbo manifold yesterday it was a long day about 7 hours invested in tiging it up.

First thing to do was make a list of the bends and the angle's we needed to cut them, next thing to do was measure the angle of rotation between the parts and start assembling the runners

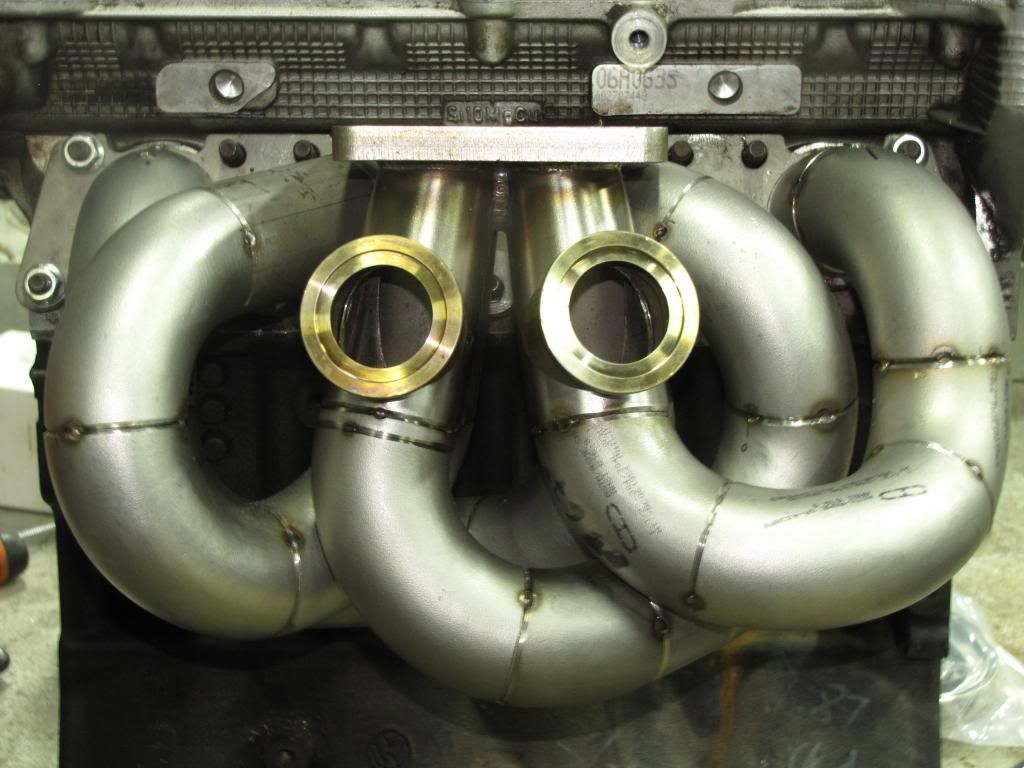

actually it when smoother than what I thought. the collector actually warped a bit ,just enough to change a few of the dimensions which we had to fix but I think everything went according to plan. one thing for sure I have no idea how manifold fabricators take into account the warp caused by welding the parts it seems that it is almost impossible to predict as with the collector which for some odd reason changed the angle of the runners by a few degrees

next thing to do is check the clearance of the runners and make sure they don't hit the transfer case (as long as I measured correctly they shouldn't)I have a friend with an engine and 02m trany sitting in a dismantled project car that I can fit the manifold on to check things out

ok pictures

First thing to do was make a list of the bends and the angle's we needed to cut them, next thing to do was measure the angle of rotation between the parts and start assembling the runners

actually it when smoother than what I thought. the collector actually warped a bit ,just enough to change a few of the dimensions which we had to fix but I think everything went according to plan. one thing for sure I have no idea how manifold fabricators take into account the warp caused by welding the parts it seems that it is almost impossible to predict as with the collector which for some odd reason changed the angle of the runners by a few degrees

next thing to do is check the clearance of the runners and make sure they don't hit the transfer case (as long as I measured correctly they shouldn't)I have a friend with an engine and 02m trany sitting in a dismantled project car that I can fit the manifold on to check things out

ok pictures

lol  actually yes...that is one thing I am sure about, the motor sits in a 15* angle so actually although it looks like the turbo sits really high up it actually only sits a few cm's over the valve cover.

actually yes...that is one thing I am sure about, the motor sits in a 15* angle so actually although it looks like the turbo sits really high up it actually only sits a few cm's over the valve cover.

what really worries me at the moment is how am I going to manage to fit a 4" DP???

seems like there isn't much room

what really worries me at the moment is how am I going to manage to fit a 4" DP???

seems like there isn't much room

Just read the thread from the start and all I can say is WOW!!!!!!! Hats off indeed to you sir.

after checking clearance for the DP a few times it came clear to me that runner #1 was sticking out too much and would probably get in the way of the DP so I redesigned the runner so it runs snug to runner # 2 it did lose a bit of overall length which means it is a bit shorter than the rest of the runners but this is a better design. I also ended up positioning booth the WG vertical to the manifold ,we also finished positioning them and also positioned and drilled holes for the EGT probes.

next week it should be all welded up

next week it should be all welded up

Similar threads

- Replies

- 10

- Views

- 6K