You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Summer Update!

Lots of work has been going on this summer and the big plan was to get the motor finished but I was having an ARP main bolt length problem I ordered 3 sets of bolts all ending up no good so now I am waiting for what I is the final set that will work with my engine girdle setup. the problem is that without the main bolts I can't get the engine block line bored for the mains. so in the mean time I have been working on the rest of the parts that needed mucking up.

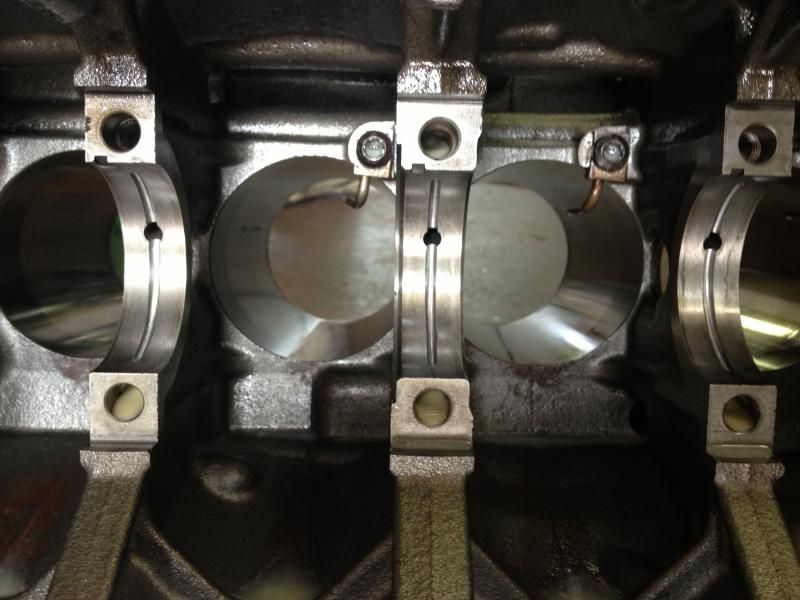

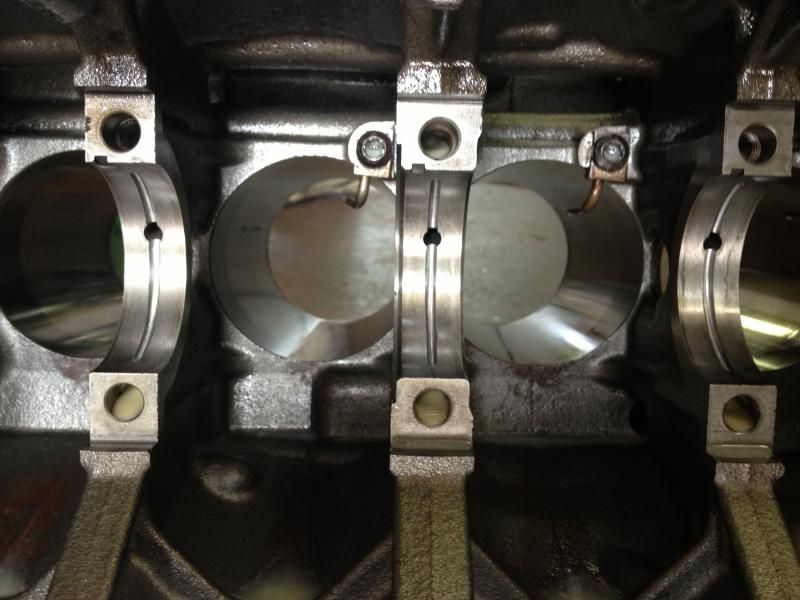

First thing was getting the engine block CNC oil groves milled for the extra oiling needed for high RPM running, I milled the groves in the main bearing and later on the bearings will get drilled for oil passages, this should help with oiling all the bearings especially the connection rods under high loads and RPM. also took advantage of the situation to get the billet main engine caps fitted on the block for line boring later on.

Started the muck up of all the oil and water lines for the turbo. I assembled a muck up motor on the stand with a spare block and head I have laying around and assembled all the parts to make sure everything fits and in order to build the oil return line which was not a small task by itself. now everything is ready I am only waiting to take the block to the shop as I explained earlier.

best tool ever !!!

Lots of work has been going on this summer and the big plan was to get the motor finished but I was having an ARP main bolt length problem I ordered 3 sets of bolts all ending up no good so now I am waiting for what I is the final set that will work with my engine girdle setup. the problem is that without the main bolts I can't get the engine block line bored for the mains. so in the mean time I have been working on the rest of the parts that needed mucking up.

First thing was getting the engine block CNC oil groves milled for the extra oiling needed for high RPM running, I milled the groves in the main bearing and later on the bearings will get drilled for oil passages, this should help with oiling all the bearings especially the connection rods under high loads and RPM. also took advantage of the situation to get the billet main engine caps fitted on the block for line boring later on.

Started the muck up of all the oil and water lines for the turbo. I assembled a muck up motor on the stand with a spare block and head I have laying around and assembled all the parts to make sure everything fits and in order to build the oil return line which was not a small task by itself. now everything is ready I am only waiting to take the block to the shop as I explained earlier.

best tool ever !!!

Got all the remaining parts for the engine build.

I decided to go with a TFSI main timing gear I the end because it has 6 bolts as opposed to the 4 bolt gear that is equipped on 1.8t engines this should help keeping the fluidamper attached to the gear under extreme load.

Modified are very own INA aluminum oil pan, the oil return needed a bit of a different angle to clear the transfer case and axle, also had to weld two blocks of aluminum to it so I could mill provisions for the bolts that would interfere because of the engine girdle at one side of the block.

Engine assembling tools came in as well, one 83mm sleeve and one bolt stretch tool from ARP.

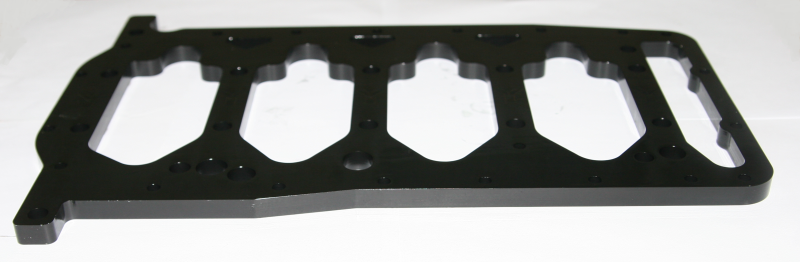

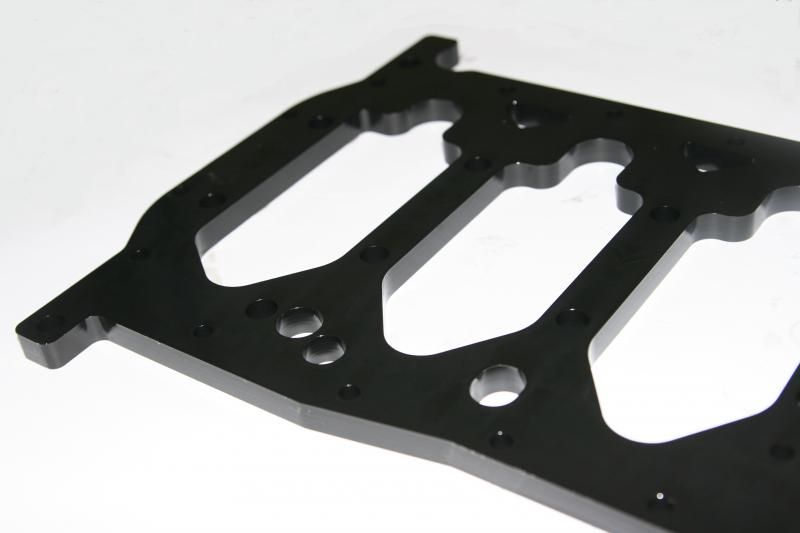

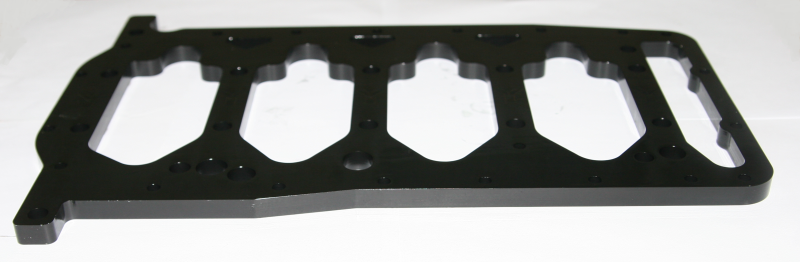

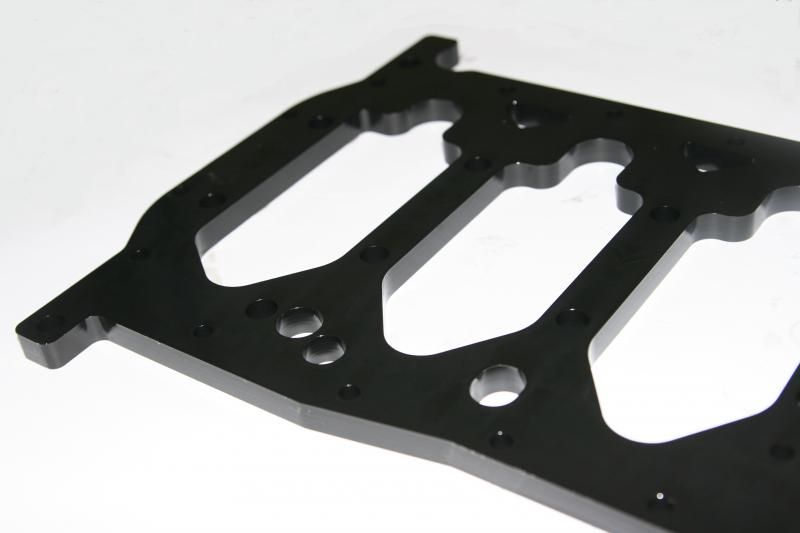

Got the CNC engine girdle i made black oxide coated just because it looks awesome! as do the billet engine caps![Cool [B)] [B)]](/forums/styles/seatcupra/oldforumsmileys/shades.gif) .

.

since it looks like my power gool has gon up i got a set of the new ID 1300 injectors for the extra fuel i am gooing to need.

I decided to go with a TFSI main timing gear I the end because it has 6 bolts as opposed to the 4 bolt gear that is equipped on 1.8t engines this should help keeping the fluidamper attached to the gear under extreme load.

Modified are very own INA aluminum oil pan, the oil return needed a bit of a different angle to clear the transfer case and axle, also had to weld two blocks of aluminum to it so I could mill provisions for the bolts that would interfere because of the engine girdle at one side of the block.

Engine assembling tools came in as well, one 83mm sleeve and one bolt stretch tool from ARP.

Got the CNC engine girdle i made black oxide coated just because it looks awesome! as do the billet engine caps

![Cool [B)] [B)]](/forums/styles/seatcupra/oldforumsmileys/shades.gif) .

.

since it looks like my power gool has gon up i got a set of the new ID 1300 injectors for the extra fuel i am gooing to need.

Shiki

Guest

Upcoming New Year update!

Well my son was born on the 6/9/2013 just about 1 month early so project was put on hold for the last part of the summer and I made no progress at all, I have just been enjoying a new life in are home.

I have yet to receive the correct set of main engine studs to work with my girdle so I am not able to do any machine work on the engine block. I hope the correct set of studs will arrive on time for me to work on the motor when I have some time off at the end of the semester.

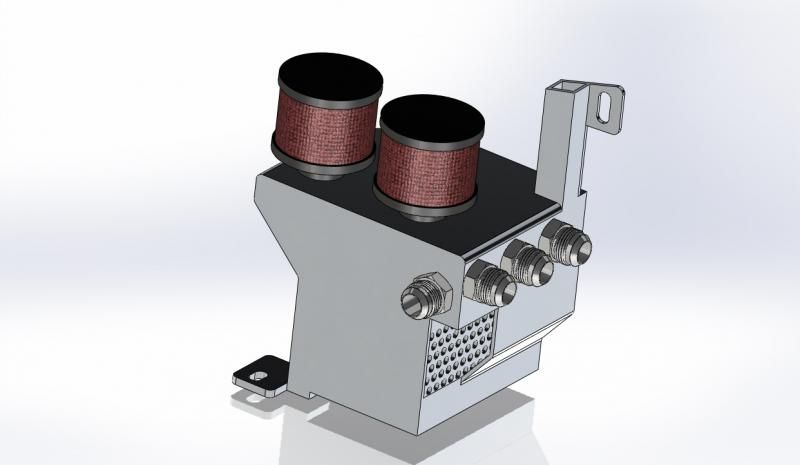

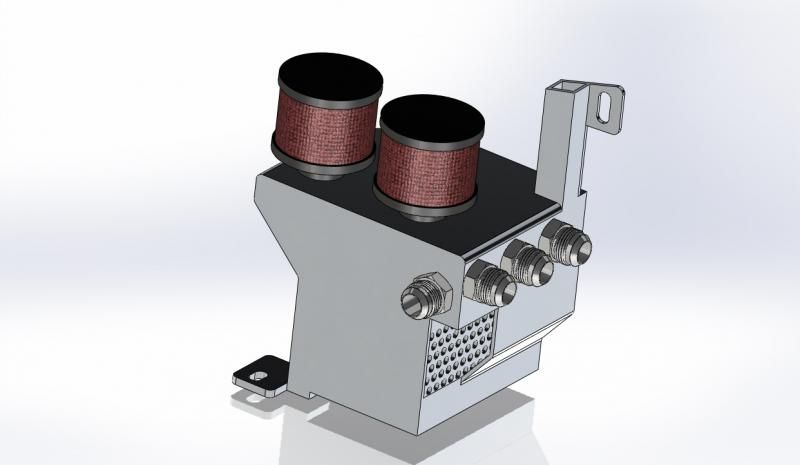

Some parts have come in, CM twin plate clutch I had specially ordered with a chromoly FW (std is aluminum) I should be taking it into the workshop soon to have the 11 bolt setup milled into the FW and crankshaft. Except for that I have been working on designing the catch can and have order a set of K&N filters for it.

Oil pump and chain have arrived I just need to add an extra link to the oil chain in order to compensate for the oil pump sitting lower because of the engine girdle. When I get round to it I also intend to change the coils wiring loom and I got a new heat shield from the TFSI motors to protect it from the heat.

New set of rear big brake mounts made from 4340 with CNC logo this is the VER-2 to replace the set I have at the moment.

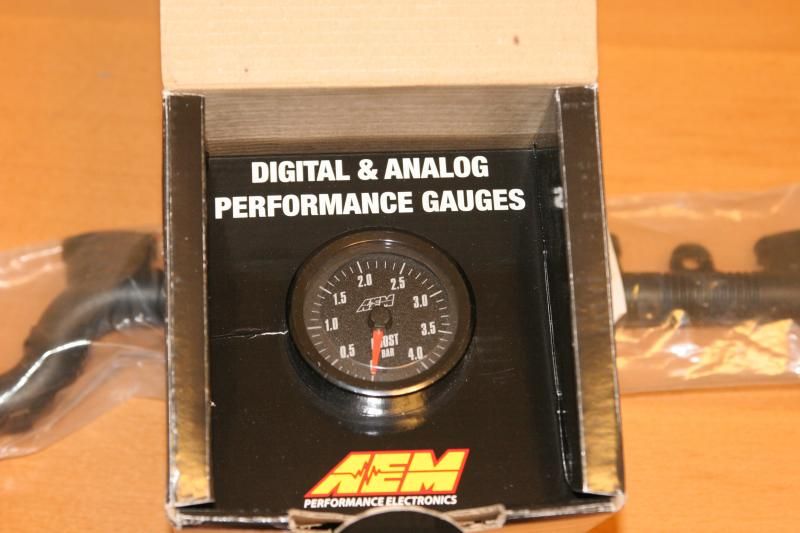

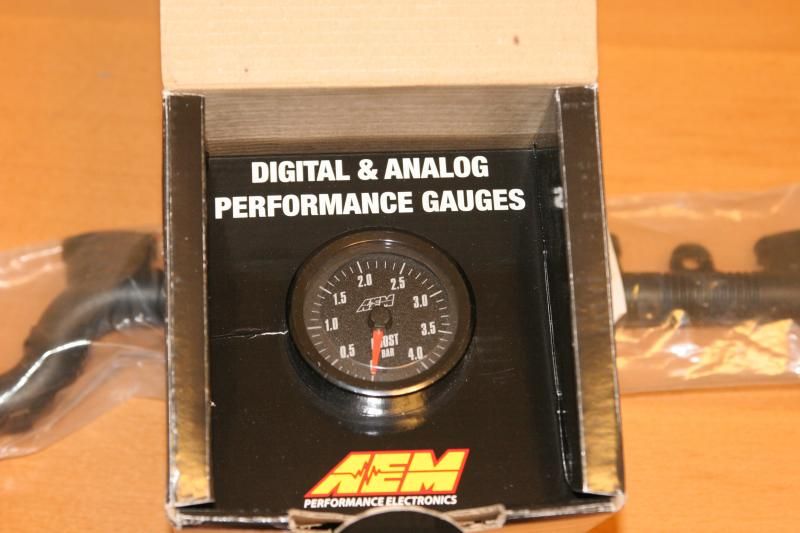

Also got an AEM Analog boost gauge …hoping to need most of it

I couldn’t find a gauge that goes all the way to 4 bar with vacuum, but vacuum is over rated its boost we are interested in lol.

Well my son was born on the 6/9/2013 just about 1 month early so project was put on hold for the last part of the summer and I made no progress at all, I have just been enjoying a new life in are home.

I have yet to receive the correct set of main engine studs to work with my girdle so I am not able to do any machine work on the engine block. I hope the correct set of studs will arrive on time for me to work on the motor when I have some time off at the end of the semester.

Some parts have come in, CM twin plate clutch I had specially ordered with a chromoly FW (std is aluminum) I should be taking it into the workshop soon to have the 11 bolt setup milled into the FW and crankshaft. Except for that I have been working on designing the catch can and have order a set of K&N filters for it.

Oil pump and chain have arrived I just need to add an extra link to the oil chain in order to compensate for the oil pump sitting lower because of the engine girdle. When I get round to it I also intend to change the coils wiring loom and I got a new heat shield from the TFSI motors to protect it from the heat.

New set of rear big brake mounts made from 4340 with CNC logo this is the VER-2 to replace the set I have at the moment.

Also got an AEM Analog boost gauge …hoping to need most of it

I couldn’t find a gauge that goes all the way to 4 bar with vacuum, but vacuum is over rated its boost we are interested in lol.

Well if anyone is interested the mounts will cost $250

Rear Porsche Cayenne Brembo calipers cost me $250

Rear Jaguar S Type R $250

Special braded lines for the swap $110

312mm Discs $140

Total cost for me was $1000

Not bad considering the only full kit sold on the market by MBT- Engineering quoted me 3128 EURO!!! For a rear brake setup with Porsche boxer rear calipers So that’s almost 4 times the price!!!

If anyone is interested you can get the mounts from me

the rest of the parts are obtainable at a salvage yard for more or less the price which I paid

sorry to dig up an old question but id be interested in the mounts.. which brembo caliper is needed? also can the bracket be adapted to use the standard caliper to function as the parking brake instead of getting the brembo parking brake?

please let me know

cheers

As I mentioned brake caliper is rear Porsche Cayenne.

I am not sure about using the OEM caliper for hand brake but it would probably be possible not sure if it will work with my mounts.

I have updated the mounts from the original design I made a few years ago since I had a few issues with the prototype and now I have them CNC milled from a billet of 4340 steel so the price is not cheap but they are aircraft quality. You can see the new mounts in my post above.

I am not sure about using the OEM caliper for hand brake but it would probably be possible not sure if it will work with my mounts.

I have updated the mounts from the original design I made a few years ago since I had a few issues with the prototype and now I have them CNC milled from a billet of 4340 steel so the price is not cheap but they are aircraft quality. You can see the new mounts in my post above.

Yes I did have a Scirocco, actually I still have it. I was building a Haldex 1.8t swap project but stopd working on it because I started my studys a few years back

Updates

Finally got the correct set of main engine studs from ARP it's been a long wait on these and this is the 4th set sent to me 117mm in length so I can finally start the work on the engine block which will be sent to the machine shop in two weeks to get line bored cylinder bored and surfaced on both sides.

Got the crankshaft back from the shop today drilled and tapped for an extra 5 bolts to hold the FW. This is an 11 bolt setup using 6 ARP bolts and 5 std OEM bolts, also got the main gear ant snout of the crankshaft drilled for two dowel pins

Last this I have left to do before sending the block in to get worked on is drill the main upper bearings for additional oiling to the conrods at high RPM. I set up this jig from a spare main cap I have with two bolts to hold the bearing shell in place while I accurately drill 4, 3mm holes in each of the 5 uper half's. You can see in the picture an example of some testing I made in a set of used bearing to make sure I don’t make any mistakes I hope to complete the work on the bearings tomorrow I will be using Vandervel/Mahle racing bearing.

last thing to do for the day was add an extra link to the oil pump chain inorder to compensate for the engine girdle. now 26 links instead of 25.

Updates

Finally got the correct set of main engine studs from ARP it's been a long wait on these and this is the 4th set sent to me 117mm in length so I can finally start the work on the engine block which will be sent to the machine shop in two weeks to get line bored cylinder bored and surfaced on both sides.

Got the crankshaft back from the shop today drilled and tapped for an extra 5 bolts to hold the FW. This is an 11 bolt setup using 6 ARP bolts and 5 std OEM bolts, also got the main gear ant snout of the crankshaft drilled for two dowel pins

Last this I have left to do before sending the block in to get worked on is drill the main upper bearings for additional oiling to the conrods at high RPM. I set up this jig from a spare main cap I have with two bolts to hold the bearing shell in place while I accurately drill 4, 3mm holes in each of the 5 uper half's. You can see in the picture an example of some testing I made in a set of used bearing to make sure I don’t make any mistakes I hope to complete the work on the bearings tomorrow I will be using Vandervel/Mahle racing bearing.

last thing to do for the day was add an extra link to the oil pump chain inorder to compensate for the engine girdle. now 26 links instead of 25.

WOW! Following day update lol.

Finished drilling the main bearing top half's must say I wasn't sure how this would turn out, it was a bit of a risk on these 190$ Vandervell bearings but it came out ok in the end and the jig worked out great!

My AEM EGT 4 Channel controller and sensors came in today, I hope to start wiring it up with the standalone engine management soon.

Next update will be engine block machining so stay tuned.

Patrick60

Guest

Patrick60

Guest

Good news, engine block went into the shop today to get the work done on it, basically the block will get bored to 83mm, line bore for the main billet caps, head deck and bottom pan rail deck surfaced for a smooth and flat surface. Also all the blue printing will be done to all clearances mainly for the main bearing and crankshaft journals. As soon as it gets back I will update and i hope I will have time in the next few weeks to start assembly on the bottom end.

Similar threads

- Replies

- 10

- Views

- 6K