D.K's LCR, #Projectcarbon. Still alive

- Thread starter D.K

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

brotjs

Guest

2 words mate.... BANG TIDY!!! lol. Awesome car mate, a lot of time and effort has clearly gone into this!

Cars now booked into AmD for next Friday to have a the de-cat fitted

And I went to see a friend yesterday about getting the front and rear bumpers re sprayed, Probably looking at around October now due to a lot of work that we're doing on the house

I'll also be redoing the lower carbon fibre splitter soon, it's started to delaminate so I'll be makeing the mk3 out of uPVC foam board and then fully wraped in carbon fibre

And I went to see a friend yesterday about getting the front and rear bumpers re sprayed, Probably looking at around October now due to a lot of work that we're doing on the house

I'll also be redoing the lower carbon fibre splitter soon, it's started to delaminate so I'll be makeing the mk3 out of uPVC foam board and then fully wraped in carbon fibre

de cat makes a difrence darrenall i need to do now is get it mapped again

I know mate

I reacently changed fuel from Sainsbury's super unleaded (97Ron) to Shell Vpower, since doing that it's been poping a lot more on over run, the decat should make them even louder

I know mateI had decat's fitted to my previous cars so I cant wait to see how it changes this one

I reacently changed fuel from Sainsbury's super unleaded (97Ron) to Shell Vpower, since doing that it's been poping a lot more on over run, the decat should make them even louder

de cat does make it alot louder and deeper

![Cool [B)] [B)]](/forums/styles/seatcupra/oldforumsmileys/shades.gif)

Interesting see what you think of the decat DK, been running your current set up a while now, I'm hoping to decat very soon.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

my decat hasnt made my car louder to b fair and not deeper sounding it has abit more raspy sound at lowrevs but sound same in high revs and barksout nice on boost like it did with sport cat

matt

matt

Made a start on a new lower splitter today (The Mk3)

The Mk1 & 2 were both made from 6mm ply,

The Mk1 was just primed and sprayed gloss black,

The under side of this soon worn down due to rubbing on speed bump's.

The sole purpose of the Mk1 was to get the shape and size right before making the the Mk2 which would be wrapped in Carbon Fibre.

Mk3, Carbon Wrapped.

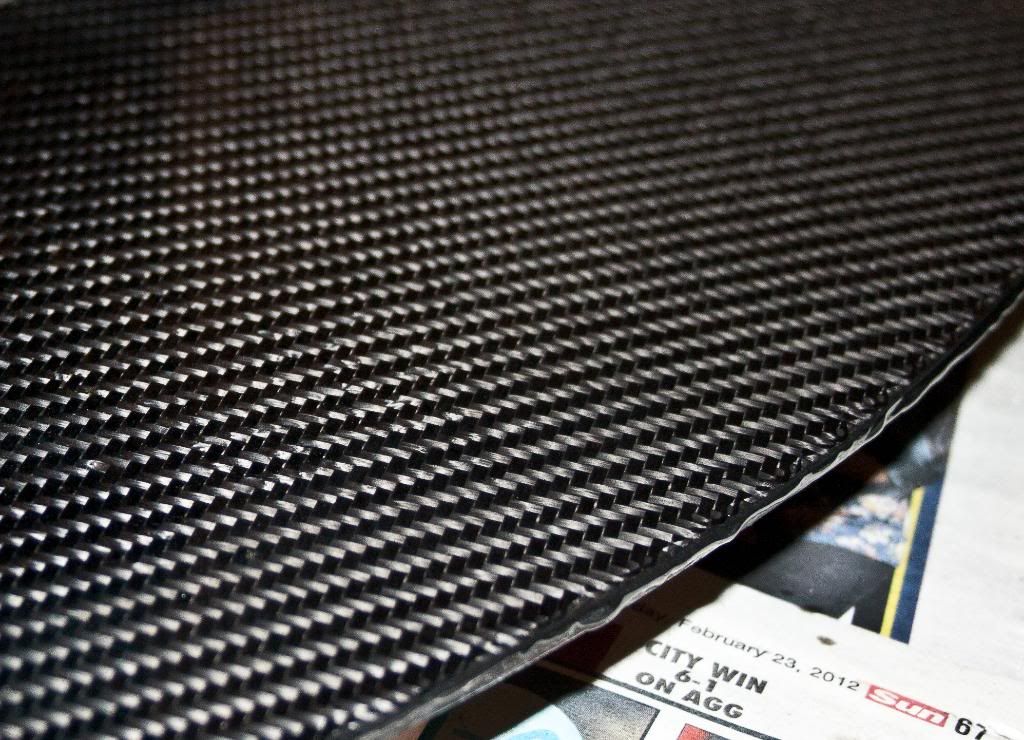

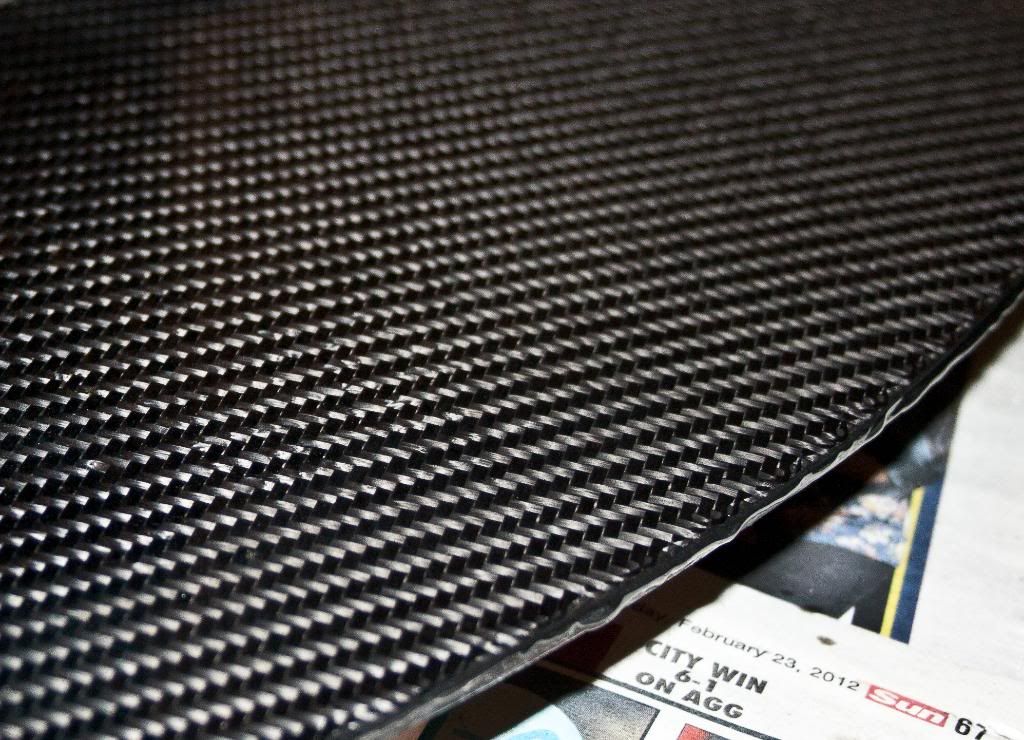

To try and limit the wear on the under side of the Mk2 both side's were wrapped in Carbon Fibre, On the underside I used a cloth that had Titainium reinforcment strand's and then applied several layers of clear resin, this has held up very well to being rubbed on speed bump's so I'll be doing the same on the Mk3. The top side was then wrapped in 2 twill Carbon, the only problem was I did'nt wrap the Carbon over the edge which left the edge of the ply exposed, the edges were built up with layers of clear resin.

But due to the punishment the lead edge takes the resin has chipped off in places allowing water to get into the ply and delaminate it.

The Mk3 had to be made from somthing that would stand up to the weather better than the Ply, I wanted to use acrlyc plastic sheet but it is very expensive so I opted for a hi density foam board.

The foam board is pretty flexible but still strong.

After releasing it it went beck to being flat straight away.

The Mk3 has been made 5mm biger to give it a better profile edge where it joins the OE LCR splitter back towards the wheel arch.

Mk2

Mk3

This might take a while to finish but the whole splitter will be wrapped in Carbon Fibre but all the edges fully cover and sealed to make it water tight

The Mk1 & 2 were both made from 6mm ply,

The Mk1 was just primed and sprayed gloss black,

The under side of this soon worn down due to rubbing on speed bump's.

The sole purpose of the Mk1 was to get the shape and size right before making the the Mk2 which would be wrapped in Carbon Fibre.

Mk3, Carbon Wrapped.

To try and limit the wear on the under side of the Mk2 both side's were wrapped in Carbon Fibre, On the underside I used a cloth that had Titainium reinforcment strand's and then applied several layers of clear resin, this has held up very well to being rubbed on speed bump's so I'll be doing the same on the Mk3. The top side was then wrapped in 2 twill Carbon, the only problem was I did'nt wrap the Carbon over the edge which left the edge of the ply exposed, the edges were built up with layers of clear resin.

But due to the punishment the lead edge takes the resin has chipped off in places allowing water to get into the ply and delaminate it.

The Mk3 had to be made from somthing that would stand up to the weather better than the Ply, I wanted to use acrlyc plastic sheet but it is very expensive so I opted for a hi density foam board.

The foam board is pretty flexible but still strong.

After releasing it it went beck to being flat straight away.

The Mk3 has been made 5mm biger to give it a better profile edge where it joins the OE LCR splitter back towards the wheel arch.

Mk2

Mk3

This might take a while to finish but the whole splitter will be wrapped in Carbon Fibre but all the edges fully cover and sealed to make it water tight

Awesome work mate, looks like I'll have to make the trip to AMD sometime next year so I can see this in real life on the car

Awesome work mate, looks like I'll have to make the trip to AMD sometime next year so I can see this in real life on the car

I'll have to try and get up to inters next year

Strong work as always Daz.

Cheers mate

The cars taken a bit of a back seat lately due to doing loads of over due jobs on the house, new windows and front door and then the whole house had to to be painted

Anyway I managed to get time to get over to AmD on Friday to have my new Milltek 3" De-cat fitted I wasn't too sure about it at first as it's quite a bit louder and has lost some of it's depth which has been replaced with more of a rasp. Normal (sensible) driving it sounds quite nice but as soon as the engine comes under load it opens up and barks even louder than before, I was worried that it sounds a bit like a chavie Saxo, all noise and no go but it has certainly got plenty of go in it

I wasn't too sure about it at first as it's quite a bit louder and has lost some of it's depth which has been replaced with more of a rasp. Normal (sensible) driving it sounds quite nice but as soon as the engine comes under load it opens up and barks even louder than before, I was worried that it sounds a bit like a chavie Saxo, all noise and no go but it has certainly got plenty of go in it

A couple of pictures from Sunday

IMG_4239 by D.Knight, on Flickr

IMG_4238 by D.Knight, on Flickr

IMG_4238 by D.Knight, on Flickr

IMG_4240 by D.Knight, on Flickr

Unfortunatly whilst playing down the lanes I must of brushed past somthing which put i nice big scratch down the side of the car not great timing with players being this coming Sunday

not great timing with players being this coming Sunday

I managed to polish the scratch out tonight when I got home using DoDo Juice Lime Prime but whilst doing it I noticed one of my DoDo juice buckets was leaking, looked underneath it and it's got 4 small crack's in the base![Furious [:@] [:@]](/forums/styles/seatcupra/oldforumsmileys/furious.gif)

Looks like I'll be paying Elite Car care a visit on Sunday

Anyway I managed to get time to get over to AmD on Friday to have my new Milltek 3" De-cat fitted

A couple of pictures from Sunday

IMG_4239 by D.Knight, on Flickr

IMG_4238 by D.Knight, on Flickr

IMG_4238 by D.Knight, on Flickr

IMG_4240 by D.Knight, on Flickr

Unfortunatly whilst playing down the lanes I must of brushed past somthing which put i nice big scratch down the side of the car

I managed to polish the scratch out tonight when I got home using DoDo Juice Lime Prime but whilst doing it I noticed one of my DoDo juice buckets was leaking, looked underneath it and it's got 4 small crack's in the base

![Furious [:@] [:@]](/forums/styles/seatcupra/oldforumsmileys/furious.gif)

Looks like I'll be paying Elite Car care a visit on Sunday

Similar threads

- Replies

- 40

- Views

- 8K

- Replies

- 4

- Views

- 484