Can anyone tell me the torque wrench settings for the driveshafts on a Leon 1.8t the ones that bolt to the gearbox and the hub nut. As I'm changing mine tomorrow if all goes well.

-

Hey Guest - Would you be interested in branded CUPRA or SEAT number plates for your car? 👉 Check out the designs and register your interest now

Torque wrench settings. Driveshafts

- Thread starter Mattyboy1

- Start date

For the internal 12 point bolts at the driveshaft flange, its 40nm if you have the m8 headed bolts, and 80nm for the m10 bolts. My 51 plate Cupra has the m10 bolts.

For the driveshaft hub nut you'll need a 30 mm 12 point socket. This should be tightened to 300nm then slackened off and then retightened to 50nm.

See this thread for more info.

For the driveshaft hub nut you'll need a 30 mm 12 point socket. This should be tightened to 300nm then slackened off and then retightened to 50nm.

See this thread for more info.

Last edited:

For the internal 12 point bolts at the driveshaft flange, its 40nm if you have the m8 headed bolts, and 80nm for the m10 bolts. My 51 plate Cupra has the m10 bolts.

For the driveshaft hub nut you'll need a 30 mm 12 point socket. This should be tightened to 300nm then slackened off and then retightened to 50nm.

See this thread for more info.

300 nm that's a lot. Then slacken off and retighten to 50 nm. Just got to get the bloody thing undone first.

Hey Matt, what driveshaft you getting - genuine or ebay ones & how much???

Just bought some off eBay they was £60 with a two year warranty. It's literally just to get through the mot as all my cv gaitors have split . If they turn out to be no good or snap I will replace with genuine ones.

I've read it was 200NM, slacken 180 degrees, re-tighten to 50nm + 60 degrees.

I'd look into it more though

I'd look into it more though

I've read it was 200NM, slacken 180 degrees, re-tighten to 50nm + 60 degrees.

I'd look into it more though

Yeah I heard it was 200nm need to find out for deffo ate though as I got to buy a new torque wrench aswell. Cheers for the reply

I've just fitted a new hub and torqued to 200nm, back 180 deg, torque 50nm + 60 deg and it is fine after 150 miles.

Bentley manual:

gives the tightening torques at

tighten to 200 nm and loosen 1/2 turn.

Turn wheel 180 degrees

Tighten Again with 50nm plus additional 60 degree turn.

Bentley manual:

gives the tightening torques at

tighten to 200 nm and loosen 1/2 turn.

Turn wheel 180 degrees

Tighten Again with 50nm plus additional 60 degree turn.

I've just fitted a new hub and torqued to 200nm, back 180 deg, torque 50nm + 60 deg and it is fine after 150 miles.

Bentley manual:

gives the tightening torques at

tighten to 200 nm and loosen 1/2 turn.

Turn wheel 180 degrees

Tighten Again with 50nm plus additional 60 degree turn.

Cheers mate that's great

What are the spline bolts like to undo. How do you stop the shaft from turning when trying to undo them.

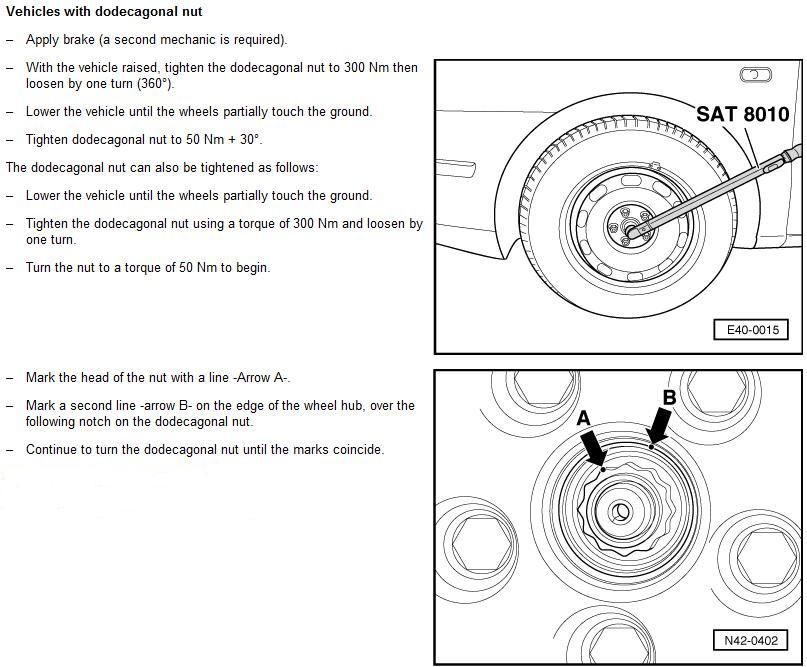

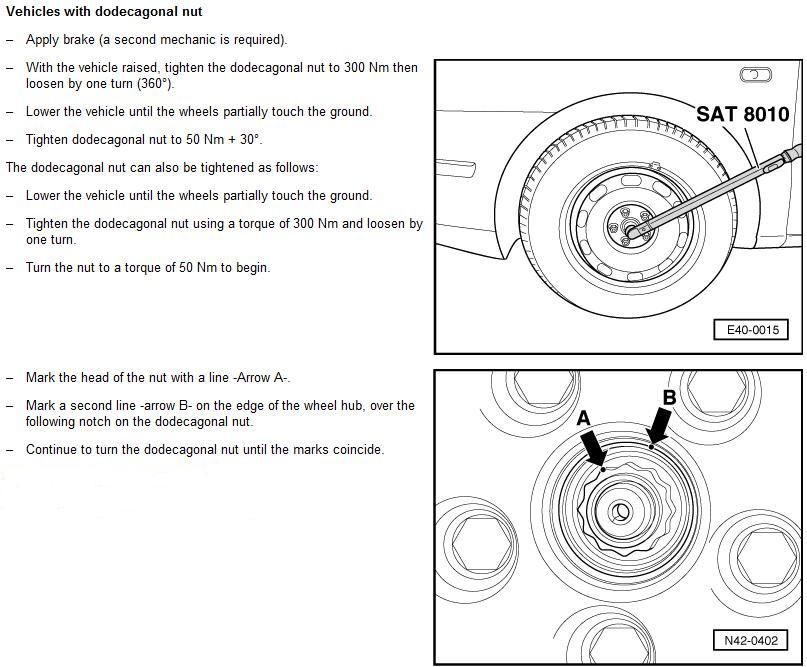

Okay then, from the ELSAWIN manual, not some American manual

The spline bolts were okay to undo, just make sure the 12-point bit has a good fit in the head of the bolt before trying to undo it. I used a screwdriver in the slots of the disc to stop it from turning.

Is it LHS or RHS you're changing?

The spline bolts were okay to undo, just make sure the 12-point bit has a good fit in the head of the bolt before trying to undo it. I used a screwdriver in the slots of the disc to stop it from turning.

Is it LHS or RHS you're changing?

Okay then, from the ELSAWIN manual, not some American manual

The spline bolts were okay to undo, just make sure the 12-point bit has a good fit in the head of the bolt before trying to undo it. I used a screwdriver in the slots of the disc to stop it from turning.

Is it LHS or RHS you're changing?

I'm doing both mate

I'm doing both mate

Passenger side spline bolts are the easier to get to, you can reach them after taking the wheel off and using an extension bar.

Driver's side I found easiest to get from underneath, as the inner CV boot can slightly get in the way if you try from other angles.

HTH

No I ain't mate gonna have a pop at them later when I get home hopefully. I snapped my torque wrench trying to get the hub nut undone . I ordered a new one but it only goes up to 210nm so will have to do it up that much for now and then torque it up to 300nm when I get another torque wrench.

Done both driveshafts now borrowed a torque wrench that went up to 300nm was a pig of a job to do as the lower ball joint wouldn't come undone just kept spinning then two of the three bolts that hold the lower ball joint to the lower arm just kept spinning. Put it all back together to find that where I was rushing and doing it in the dark I've put the lower ball joints on the wrong side as I didn't realise they was left and right handed. So now gotta swap them round in the morning before the mot.

Sorry to drag up an old thread - it's a bad idea to use a torque wrench to undo tight fixings. The torque measurement could be damaged if overtorque is required to remove.

I'd recommend a 900mm breaker bar and impact type hex socket when removing hub bolts.

To help remove the ball joint fixings - a 'key' type torx tool can be inserted into the top of the bolt thread and braced against a *solid* part of the hub (i.e. NOT ABS ring) so it doesn't spin whilst removing.

I covered a lot of this in a different thread around Sept 2012.

Alex

I'd recommend a 900mm breaker bar and impact type hex socket when removing hub bolts.

To help remove the ball joint fixings - a 'key' type torx tool can be inserted into the top of the bolt thread and braced against a *solid* part of the hub (i.e. NOT ABS ring) so it doesn't spin whilst removing.

I covered a lot of this in a different thread around Sept 2012.

Alex

Last edited:

Similar threads

- Replies

- 23

- Views

- 2K