Day 10

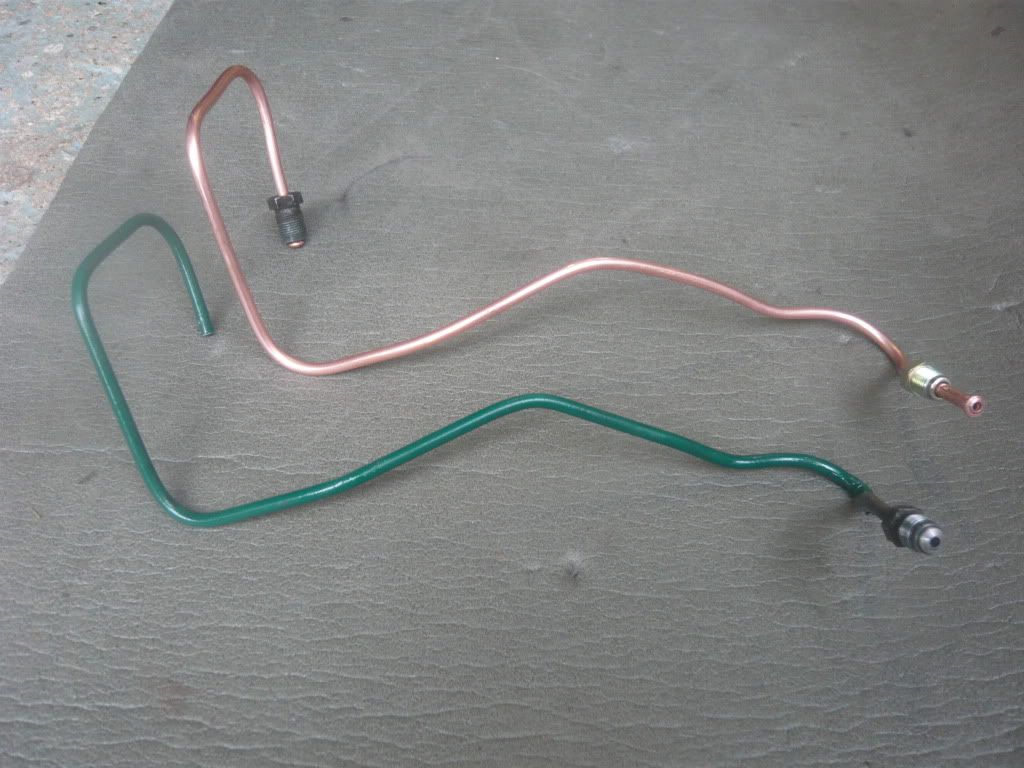

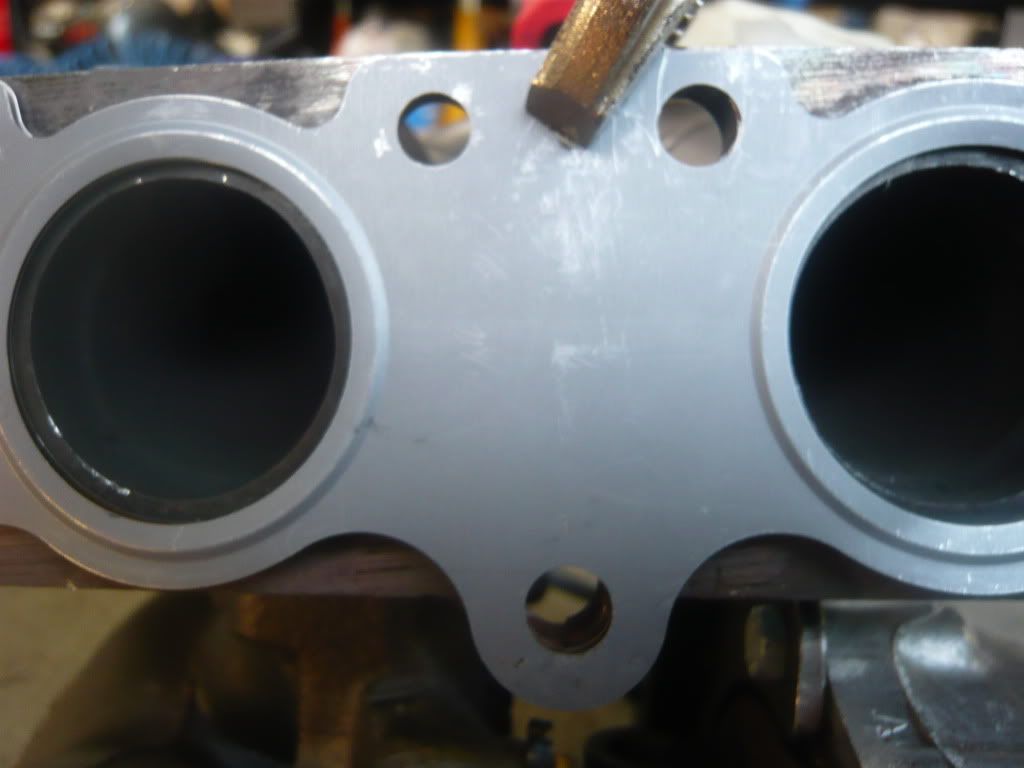

Picking up where I last left off we finished off my HiSpec brake conversion by making up the offside hard brake line:

As per the above pic, we made the mistake of bending the copper line to shape before getting it lined up and fitted in the engine bay. By the time we'd got it in place and where it needed to be it had become so bent out of shape that it was pretty much beyond repair so we took a different approach and put a new, straight line into the engine bay and bent it into shape in situ which proved much easier and effective.

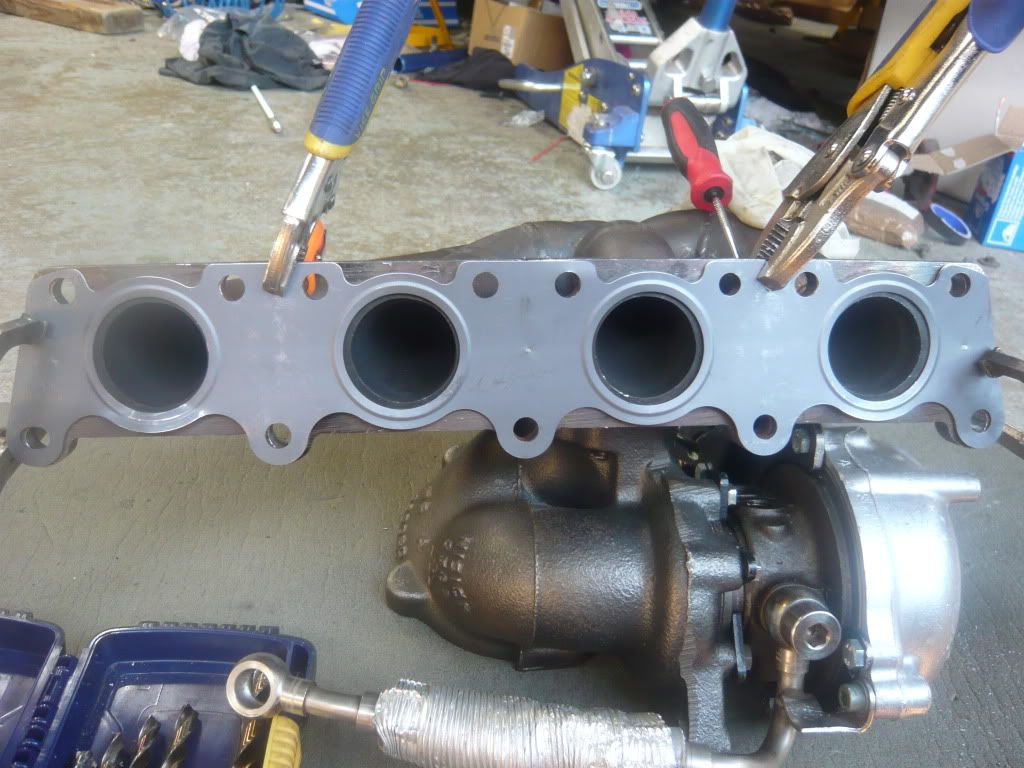

We then tried to finish off the brakes by affixing the braided lines to the calipers but found these were some 70-80mm too short as the kit was made up for a MK2 Golf GTI and not specifically an

Ibiza. A quick phone call to HiSpec resolved the situation and they were happy to make up a second set to the correct length of 49cm free of charge

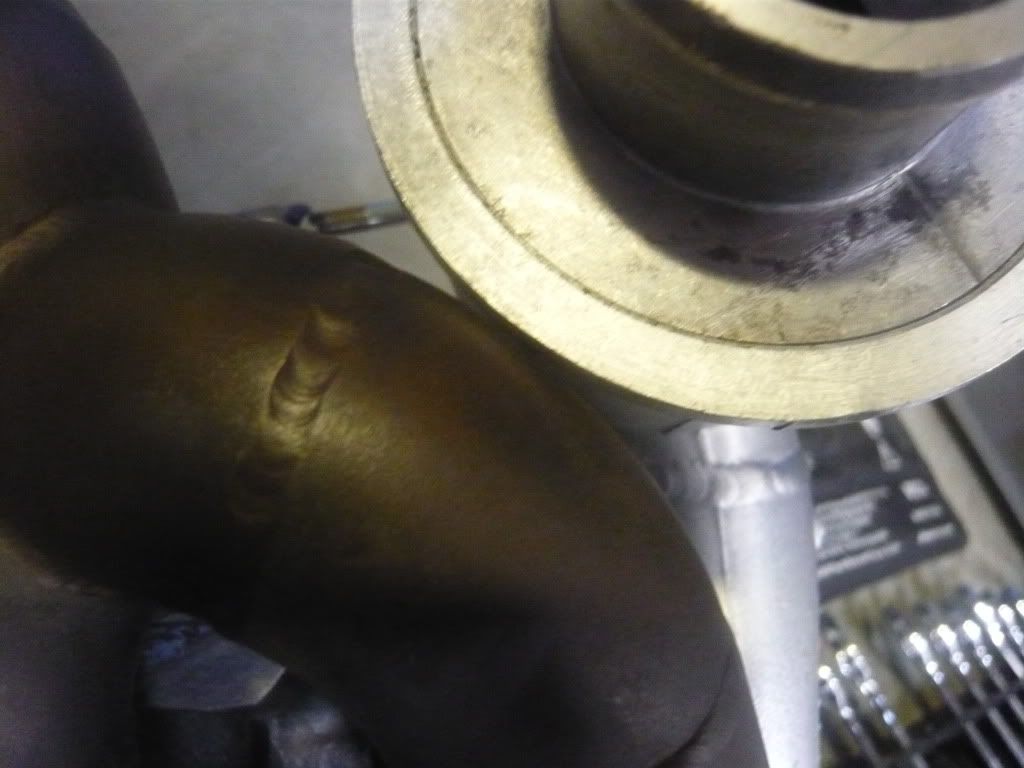

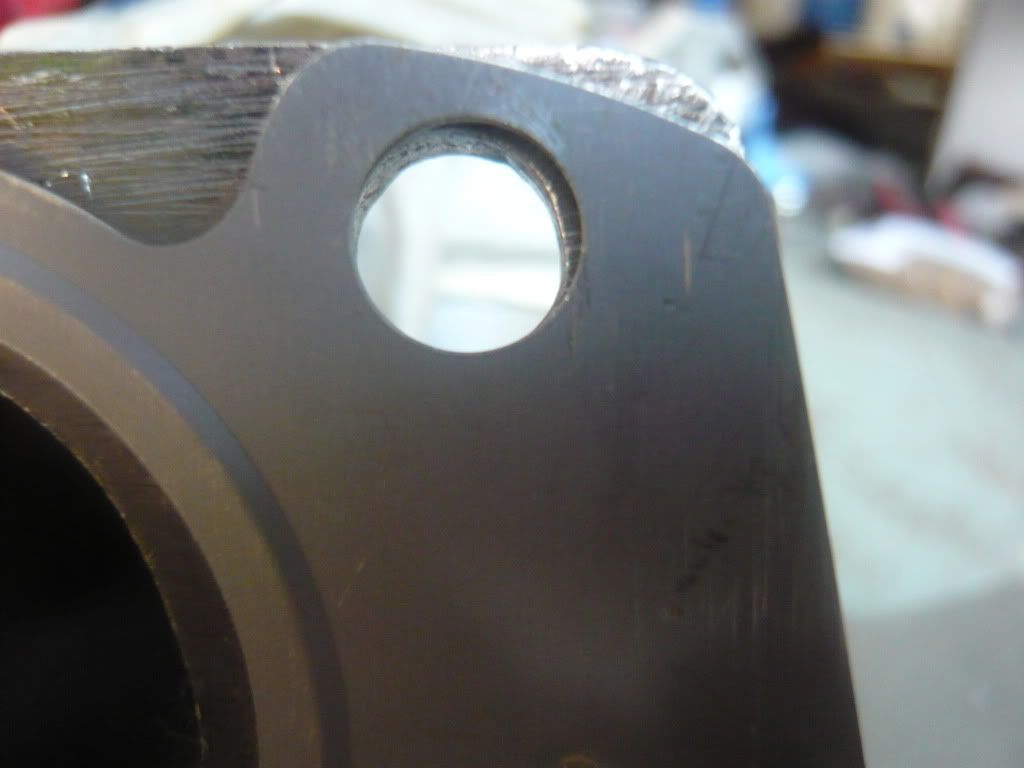

Then, judgement day as we decided to try and fit a wheel over the brakes to see if the spokes cleared the calipers. By my initial calculations I expected 2-3mm at best but once lined up I was pleasantly surprised to find a comfortable 3-4mm:

This completed the brakes, offering a nice alternative to the Wilwoods that fit straight under standard Cupra alloys

To finish off the night we then decided to take another shot at the fuel pump, using Benny's picture as a good

guide. After a few minutes fiddling we found that we did have it in the right place as suspected (lined up with the arrows on the tank and pump) but we'd struggled with getting the ring seal to secure in place.

Upon closer inspection we found that the inner thread on the seal only has one pickup, meaning you have to screw it a full rotation before it secures itself and sits flush as expected. We had expected it to sit flush much sooner and so had questioned whether the pump was in correctly when in fact all we had to do was persevere screwing it in for a full rotation before it sorted itself out

That finished the evening off nicely, progress at last!