You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'll be checking the plugs tonight and getting a mate to do a compression test to see where things stand, though I'm dubious as to how accurate this will be if oil is seeping through the rings and creating a seal.

I'll try and get a bore scope in there to check the tops of the pistons too.

I'm wondering whether it could also be a worn oil pump or some crap stuck in the relief valve?

Symptoms I'm dealing with:

- Low oil pressure at idle (8-12 PSI once warm)

- Using ~100ml of oil per 100 miles

- Nothing in the catch tank

- No smoking or signs of any leaks

- No noises from the engine, appears to be running fine

I'm concerned it's an early sign of something serious so I hope I can get it diagnosed now if that is the case rather than wait for something expensive to go wrong.

I'll try and get a bore scope in there to check the tops of the pistons too.

I'm wondering whether it could also be a worn oil pump or some crap stuck in the relief valve?

Symptoms I'm dealing with:

- Low oil pressure at idle (8-12 PSI once warm)

- Using ~100ml of oil per 100 miles

- Nothing in the catch tank

- No smoking or signs of any leaks

- No noises from the engine, appears to be running fine

I'm concerned it's an early sign of something serious so I hope I can get it diagnosed now if that is the case rather than wait for something expensive to go wrong.

Well, just finished a compression test and all appears to be fine in that aspect (results after cranking for 5 secs, after removing the fuel pump fuse and holding the butterfly open to ensure all results are even):

#1: 190 PSI

#2: 185 PSI

#3: 195 PSI

#4: 200 PSI

Looking at the plug tips there's not much to say there either. #1 did have a small amount of carbon deposit on the electrode and was generally darker than 2, 3 and 4 but nothing extreme. I'll post pics up shortly.

We also put a bore scope in each cylinder which didn't reveal anything unusual and there was no trace of any oil in the intercooler pipe before the throttle body.

We've cleaned the plug tip and put it back into another cylinder so we can monitor what happens over time. I seem to remember cylinder 1 being slightly darker than the others when we changed these out 2,000 miles ago.

After a 3 mile drive from cold the oil pressure gauge was reading 30-40 PSI on steady state cruising and just 11 on idle, but there is no smoke or noise at all and temps are fine. No contamination in the coolant either.

Next up we're going to get hold of a manual oil pressure gauge to compare against my own and try a cylinder leak test for a bit more insight.

It's difficult to take much away from this when the car itself appears to be running absolutely fine but I'd rather err on the side of caution. If that reveals nothing further then I could check the oil pickup, and maybe the relief valve? It could just be a dodgy sensor so we'll see

#1: 190 PSI

#2: 185 PSI

#3: 195 PSI

#4: 200 PSI

Looking at the plug tips there's not much to say there either. #1 did have a small amount of carbon deposit on the electrode and was generally darker than 2, 3 and 4 but nothing extreme. I'll post pics up shortly.

We also put a bore scope in each cylinder which didn't reveal anything unusual and there was no trace of any oil in the intercooler pipe before the throttle body.

We've cleaned the plug tip and put it back into another cylinder so we can monitor what happens over time. I seem to remember cylinder 1 being slightly darker than the others when we changed these out 2,000 miles ago.

After a 3 mile drive from cold the oil pressure gauge was reading 30-40 PSI on steady state cruising and just 11 on idle, but there is no smoke or noise at all and temps are fine. No contamination in the coolant either.

Next up we're going to get hold of a manual oil pressure gauge to compare against my own and try a cylinder leak test for a bit more insight.

It's difficult to take much away from this when the car itself appears to be running absolutely fine but I'd rather err on the side of caution. If that reveals nothing further then I could check the oil pickup, and maybe the relief valve? It could just be a dodgy sensor so we'll see

Last edited:

ian_cupra

Guest

Nice one, how's things going mate?

I'm looking into track days at Cadwell at the mo for later in the year so I'll give you a shout if you're up for it?

i've only just noticed this, haha. Not been on here for awhile though.

Yeah i'll come down if you do a cadwell trackday, i'm trying to get mine sorted, but money is tight still due to house etc...

Hows things going your end?

I'll text you when I get something sorted. Even if you don't bring yours out would be useful to have a passenger who knows the corners

Yeah things are good with me thanks, hoping to get a few more sessions in over the summer months where possible, maybe even a Spa trip later in the year so we'll see.

How's the house coming along? You got that cage in yet?!

ian_cupra

Guest

ian_cupra

Guest

Nice one cheers mate, will keep that in mind

no worries, will save you a few bob.

house is almost sorted now.

haha cage is still sat in the garage

haha, get on it!

Right, arranged to have a cylinder leak test over the weekend to verify the rings are all fine and then it's back over to Bill sometime next week to check the oil pressure with a manual gauge kit as well as stock back up on some methanol.

Speaking of which...as per this earlier post I've been doing some further reading into water/methanol concentrations and am now curious as to whether my particular setup would benefit from a more water concentrated mix. Stick with me on this one...

Bill has mapped the car with no fuelling adjustments made for the WMI, meaning that it's contribution to fuel is "on top" of what the ECU tells the injectors to throw in. This effectively means it's contributing to a rich AFR on boost, erring on the side of caution with regards to controlled EGTs and ensuring I don't run lean and starting melting expensive things. All well and good, especially as it means my fuelling will remain OK should the WMI fail for whatever reason (already happened once).

However... I've always used a 50:50 mix of water/methanol on the understanding that water offers a higher latent heat of vaporisation than methanol, making it more efficient at cooling - particularly inside the combustion chamber. Methanol on the other hand is a fuel with a high octane rating of 116, meaning it can be burnt safely under higher cylinder pressures to make more power.

So, the theory as I understood it was more methanol = more power, and we use water to offer greater temperature control. Being a fuel, methanol is combustable giving it _potential_ to be used to make more power, water is not. The key word there being potential, i.e. under the right conditions.

A high octane fuel won't automatically give you more power, it must be used in the right conditions to yield any gains, remembering that the octane rating is only a measure of how resistant a fuel is to detonation. That's why filling a 15 year old 1.1 Fiesta is unlikely to see any power benefit from VPower; it's only when we can tune the car to utilise the _potential_ the high octane rating offers that we can see any performance gains. In the case of the Cupra using the ME7 management, fuelling and timing can be dynamically adjusted over time by the ECU to make more power by adding ignition advance.

The higher the octane mixture of the fuel being injected into the cylinders, the more resistant to detonation it becomes and the more advance we can run, until cylinder pressure is increased to such an extent it ensues knock. Power can also be made by adjusting the AFR in accordance with the extra methanol being burned, as well as the potential to run higher levels of boost without knock.

If we apply this theory to my setup; the methanol itself is not being accounted for in the fuelling set by the map so I am simply running rich under boost. My turbo is also already running as much boost as it can possibly produce; so there's no gains to be had there either. The only way I can make more power from this setup (without adjusting fuelling so as to rely on WMI; not clever) is to advance the ignition timing.

To advance the ignition timing I need an optimum concentration of water/methanol that prevents knock. With a high octane count, methanol does contibute towards this; but not as much as water. While water doesn't have an octane rating, it does have a much higher latent heat of vaporisation making it much more effective at controlling combustion temperatures and preventing pre-ignition. This means it is still effectively increasing the overal octane rating of the mixture, more so than the methanol alone.

By using a higher concentration of water to methanol my logic is that I can better control cylinder temperatures to reduce knock and achieve more ignition advance than a 50:50 mix. It's allowing more knock-limited performance. Consequently, the reduced concentration of methanol in the cylinders will result in a slightly leaner fuel mixture achieving a higher efficiency of combustion; all resulting in more power. As the fuelling in my map isn't being touched there's no risk of running lean should the WMI fail; I'm simply adjusting the margins to maximise power from my particular setup. As my RR results show AFRs dip into the 10s then I believe there is plenty of headroom.

From what I have read it seems that methanol is more effective at cooling IATs in the intake track whereas water is better at controlling combustion temperatures. Ergo, if I log IATs and CFs while adjusting my WMI concentrations and keeping an eye on my wideband it should be possible to fine tune an optimal balance.

Whether this equates to real world figures is another question, but if every 3 degrees of advance accounts for ~10 BHP then it's entirely possible.

For anyone interested, this is what I have been reading over:

http://www.my350z.com/forum/forced-induction/446954-have-a-water-meth-kit-come-in-here-4.html

http://www.aquamist.co.uk/vbulletin/showthread.php?p=13107

This one is probably the most relevant to my above rationale: http://www.aquamist.co.uk/vbulletin/showthread.php?t=1334

<discuss>

Last edited:

OK so last night I had a cylinder leak test done as an extra precautionary check to see whether the rings are worn. Compared alongside the compression test results from last week:

I'm not sure what's considered a good level of compression or an excessive % of leakage, though the figures are reasonably consistent across all cylinders with a small standard deviation so I'm fairly sure this discounts any ring wear.

Starting the car up last night I saw cranking pressure of 70 PSI which dropped to 35 within 30 seconds, and once warmed up on idle dropped as low as 5, though fluctuating up to around 20 fairly sporadically. Normal driving sees ~30-40 PSI and it goes higher when I hit boost.... all a bit weird.

Next step is to check the actual accuracy of the gauge itself so I'm taking a trip over to Badger5 tonight so Bill can compare these readings against a mechanical gauge kit. If I was really seeing 5 PSI on idle you'd surely expect to hear some knocking, yet it sounds absolutely normal? Further updates to follow later

Code:

Cylinder Compression % leak

1 190 PSI 4

2 185 PSI 8

3 195 PSI 6

4 200 PSI 2I'm not sure what's considered a good level of compression or an excessive % of leakage, though the figures are reasonably consistent across all cylinders with a small standard deviation so I'm fairly sure this discounts any ring wear.

Starting the car up last night I saw cranking pressure of 70 PSI which dropped to 35 within 30 seconds, and once warmed up on idle dropped as low as 5, though fluctuating up to around 20 fairly sporadically. Normal driving sees ~30-40 PSI and it goes higher when I hit boost.... all a bit weird.

Next step is to check the actual accuracy of the gauge itself so I'm taking a trip over to Badger5 tonight so Bill can compare these readings against a mechanical gauge kit. If I was really seeing 5 PSI on idle you'd surely expect to hear some knocking, yet it sounds absolutely normal? Further updates to follow later

New Cylinders (145-203 psi) Wear limit (102 psi) Maximum difference between cylinders 44 psi

Theyre super healthy figures imo.

I take it the car was up to temp when the tests were done? Does it smoke or burn oil? Plugs look ok? Oil in the inlet or fmic pipes?

Id go for a dodgy sender/gauge. Those numbers seem consistantly low.

Theyre super healthy figures imo.

I take it the car was up to temp when the tests were done? Does it smoke or burn oil? Plugs look ok? Oil in the inlet or fmic pipes?

Id go for a dodgy sender/gauge. Those numbers seem consistantly low.

Cheers for the feedback Phil. Yeah the car was warm when doing both tests. The engine has covered 71k, with new rods and big end bearings at 67,000.

No smoke at all, only an occasional small puff when flooring it after a period of steady-state cruising which I presume is also normal.

Plugs also look fine and there's no oil in the IC pipe by the throttle body, though I've not checked the one immediately after the turbo yet.

I do appear to be burning a bit of oil, about 100ml every 100 miles which is what initially raised my suspicions as I just can't account for where it's going

I'm also suspicious of a dodgy sender, though just want to discount anything more serious. Rather safe than sorry.

No smoke at all, only an occasional small puff when flooring it after a period of steady-state cruising which I presume is also normal.

Plugs also look fine and there's no oil in the IC pipe by the throttle body, though I've not checked the one immediately after the turbo yet.

I do appear to be burning a bit of oil, about 100ml every 100 miles which is what initially raised my suspicions as I just can't account for where it's going

I'm also suspicious of a dodgy sender, though just want to discount anything more serious. Rather safe than sorry.

Last edited:

Well just got back from Bill's after plumbing in a mechanical gauge where the sender normally sits on the oil filter housing and it looks as though it's just the sender that is goosed, giving false readings.

The mechanical gauge was showing a solid 32 PSI on idle when the electronic sender was telling me anything between 5 and 18

At ~3,000 RPM pressure rose to around 60 PSI which all seems normal.

Overall it's good news though as I now know that the engine itself is running fine, so just a sender to replace

While I was there I had another good nose at the rolling road, which is the same one I got my printout from at GotBoost in February so it'll be interesting to get another run when Bill's got it fully calibrated to see how the figures compare.

As always, thanks again to Bill and Tony for being on-hand to help, very much appreciated

The mechanical gauge was showing a solid 32 PSI on idle when the electronic sender was telling me anything between 5 and 18

At ~3,000 RPM pressure rose to around 60 PSI which all seems normal.

Overall it's good news though as I now know that the engine itself is running fine, so just a sender to replace

While I was there I had another good nose at the rolling road, which is the same one I got my printout from at GotBoost in February so it'll be interesting to get another run when Bill's got it fully calibrated to see how the figures compare.

As always, thanks again to Bill and Tony for being on-hand to help, very much appreciated

Well just got back from Bill's after plumbing in a mechanical gauge where the sender normally sits on the oil filter housing and it looks as though it's just the sender that is goosed, giving false readings.

The mechanical gauge was showing a solid 32 PSI on idle when the electronic sender was telling me anything between 5 and 18

At ~3,000 RPM pressure rose to around 60 PSI which all seems normal.

Overall it's good news though as I now know that the engine itself is running fine, so just a sender to replace

While I was there I had another good nose at the rolling road, which is the same one I got my printout from at GotBoost in February so it'll be interesting to get another run when Bill's got it fully calibrated to see how the figures compare.

As always, thanks again to Bill and Tony for being on-hand to help, very much appreciated

Thats good news then.

You should go over this weekend when Craig is at Bills.

Yeah I would have been up for that but I'm out of the country next week with work. I'm planning on spending a morning back over at Badger5 in August in some point though to do some extensive logging on the dyno and fine tune the map to see if there's anything further to be gained

Bill's got a 200 BHP Civic coming in with Craig on Saturday to see how it fares

After getting in touch with VEI gauges about my oil pressure sender they've kindly agreed to replace it free of charge, even though it's more than 12 months old, on the basis I explained it's only been fitted to the car for ~8 months since it's actually been back on the road (covering only 5,000 miles) - can't say fairer than that!

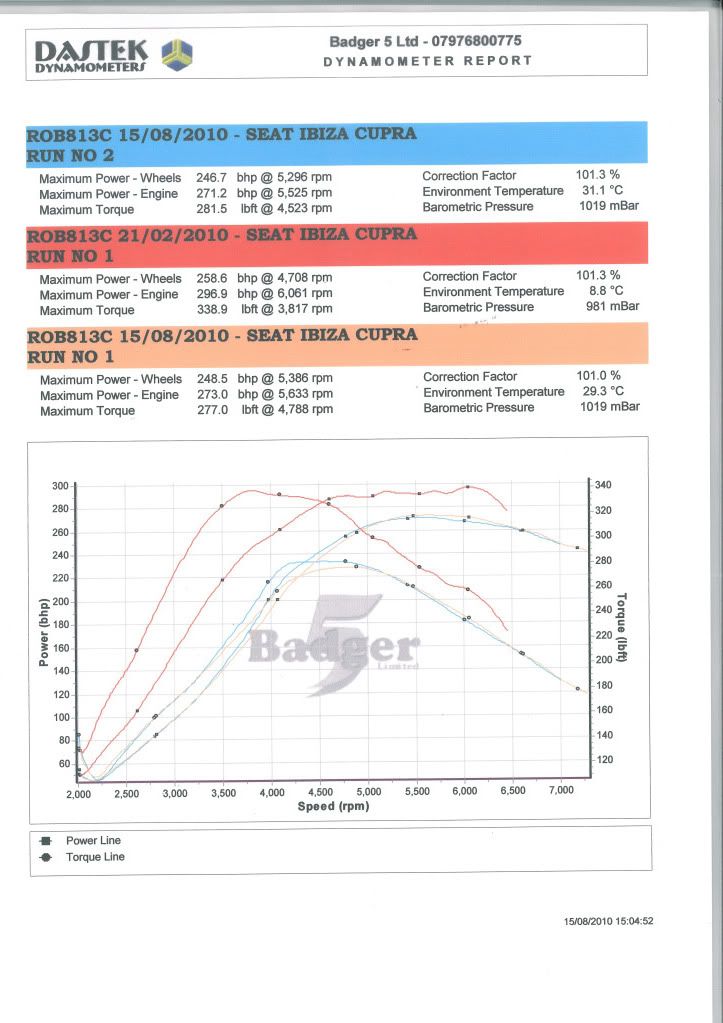

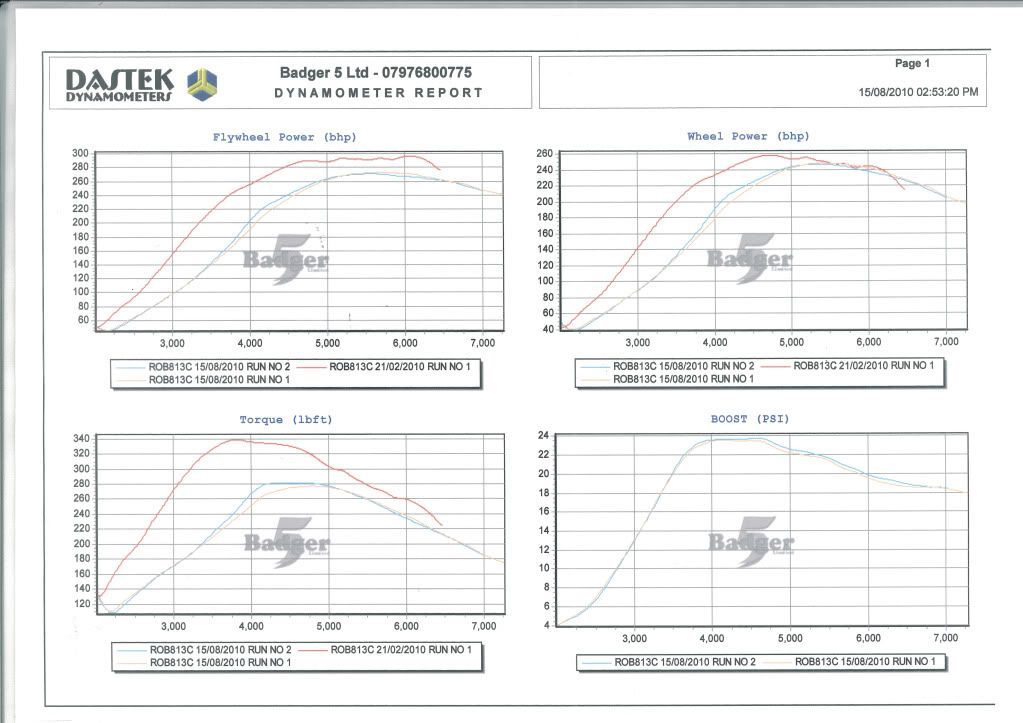

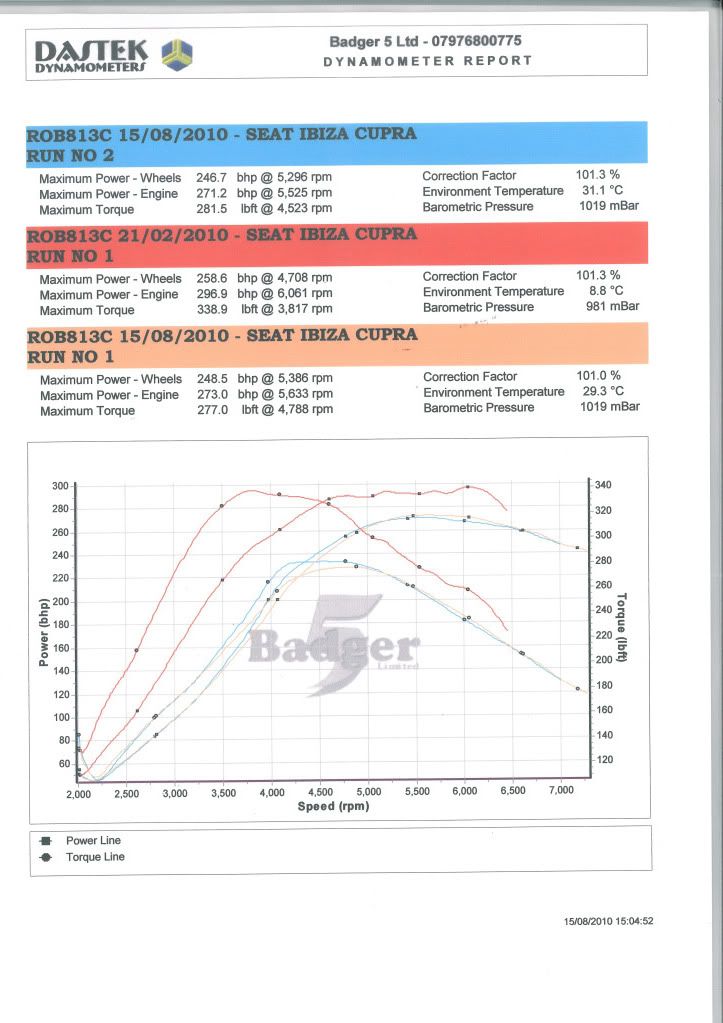

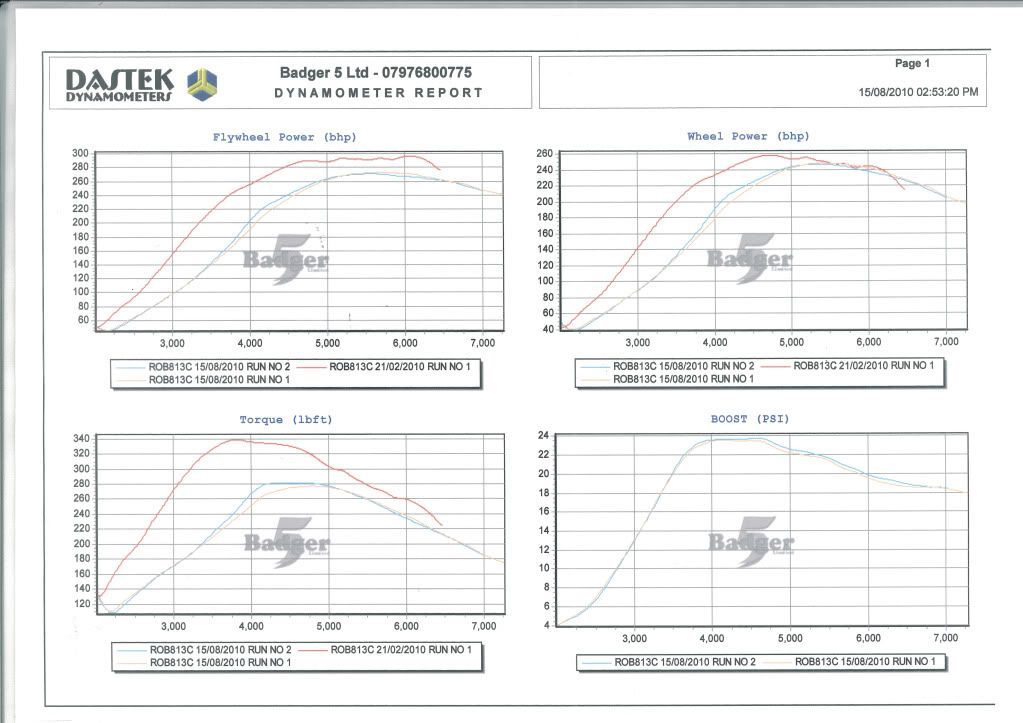

So... on Sunday I headed over to Badger5 to spend some time on the dyno, making sure everything was running OK and optimising my fuelling, which also gave a chance to compare my previous rolling road results on the same dyno when it was owned by Craig at GotBoost. The results were "interesting" to say the least.

Previously the car made 296.9 BHP and 344.4 lb/ft with 8 Deg C ambient temps.

After 5-6 runs on the same dyno since Bill has calibrated it as he sees fit I saw very different, but consistently repeatable results with a best run of 273 BHP and 282 lb/ft with ambient temps of 31 Deg C.

Peak airflow was down to 215 g/s from 227 g/s which accounts for an approximate drop of 284 BHP down to 269 BHP - probably accountable from much warmer, less dense air being sucked past the MAF.

Peak boost of 24 PSI is still being met, with 6 degrees of ignition advance thanks to WMI which kept IATs in the 20s run after run.

Obviously a huge difference in ambient temps is going to account for some discrepancy between these results, though it's the curves themselves that paint a very different picture when compared side-by-side. My initial run at GotBoost is shown in red below, vs my latest runs at Badger5:

Notice how the power appears to come in much lower in the rev range compared to my latest runs, which just doesn't make sense... even running the car on different ramp rates we weren't able to emulate these characteristics. Wheel spin would appear to be the only real plausible explanation here, which we saw none of on Sundays runs.

So, all a bit strange, though these latest figures would appear more credible than the last so perhaps not quite the torque monster I'd been led to believe!

Initially this was a bit depressing to watch on the dyno, but not forgetting that the car isn't actually down on any power and happily educates M3s, RS4s and a fair proportion of Porsches then it doesn't actually change anything, other than perception.

For a hybrid like mine that's running all the bells and whistles I'm intrigued as to what "real" figures others will see on this particular dyno, time will tell

This aside, the map itself seemed pretty much bang on with a nice smooth power curve and the car is running really well, with some minor fuel trimming adjustments made to help even things out.

Next up may be Castle Combe for an open track day in early October, unless I opt for a session on the Action day, we'll see

Previously the car made 296.9 BHP and 344.4 lb/ft with 8 Deg C ambient temps.

After 5-6 runs on the same dyno since Bill has calibrated it as he sees fit I saw very different, but consistently repeatable results with a best run of 273 BHP and 282 lb/ft with ambient temps of 31 Deg C.

Peak airflow was down to 215 g/s from 227 g/s which accounts for an approximate drop of 284 BHP down to 269 BHP - probably accountable from much warmer, less dense air being sucked past the MAF.

Peak boost of 24 PSI is still being met, with 6 degrees of ignition advance thanks to WMI which kept IATs in the 20s run after run.

Obviously a huge difference in ambient temps is going to account for some discrepancy between these results, though it's the curves themselves that paint a very different picture when compared side-by-side. My initial run at GotBoost is shown in red below, vs my latest runs at Badger5:

Notice how the power appears to come in much lower in the rev range compared to my latest runs, which just doesn't make sense... even running the car on different ramp rates we weren't able to emulate these characteristics. Wheel spin would appear to be the only real plausible explanation here, which we saw none of on Sundays runs.

So, all a bit strange, though these latest figures would appear more credible than the last so perhaps not quite the torque monster I'd been led to believe!

Initially this was a bit depressing to watch on the dyno, but not forgetting that the car isn't actually down on any power and happily educates M3s, RS4s and a fair proportion of Porsches then it doesn't actually change anything, other than perception.

For a hybrid like mine that's running all the bells and whistles I'm intrigued as to what "real" figures others will see on this particular dyno, time will tell

This aside, the map itself seemed pretty much bang on with a nice smooth power curve and the car is running really well, with some minor fuel trimming adjustments made to help even things out.

Next up may be Castle Combe for an open track day in early October, unless I opt for a session on the Action day, we'll see

Last edited:

ian_cupra

Guest

you have got to love the dyno lottery. i take it your trusting Bill's readings more than the previous ones?

You need to get yourself to cadwell park mate. Could do with seeing how yours compares to mine, especially with the WMI in yours

You need to get yourself to cadwell park mate. Could do with seeing how yours compares to mine, especially with the WMI in yours

Definitely so - the results that Bill has seen on this dyno with other cars vs book figures makes it very accurate in my eyes. A very happy reading before it would now appear - but good for pub talk

Yeah there's a day at Cadwell on the 11th October I'm also looking at so will keep you posted mate

Yeah there's a day at Cadwell on the 11th October I'm also looking at so will keep you posted mate

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 41

- Views

- 11K

- Replies

- 0

- Views

- 2K