ok, so a quick

guide from start to finish. I wish i'd taken more photos but ill just have to describe stuff as i go along...

the parts list:

Seeeduino V3.0 (Atmega 328P) Arduino Compatible £17.99

RGB Backlight 16x2 Character LCD - 5V £9.88 (im using a serial board so my codes set up for that but this should be easy to change the code for)

Mini Push Button Switch £0.17

10K Ohm resistor £0.11

all available at proto-pic.co.uk

MPX4250AP pressure sensor from freescale.com if you ask for a sample they'll send you a MPX4250GP for around $6 shipped.

The AP will measure VAC and boost (-14psi to +21psi), The GP will measure upto 36psi boost

that comes to a total of £28.15 + $6 assuming you have some wire on hand (i used some old cat5 networking cable) and a bit of soldering skills

The map sensor is analog so will need 3 wires to it, 0v/+5v/signal. the arduino calculates the boost based on the voltage returned to it from the signal wire.

i spliced into the fpr for the boost line following some of the guides on here. then i was just a case of plugging in the map sensor and wiring it up.

i fed my

network cable through the bulkhead into the engine bay as im planning to run more sensors into the system at a later date. cat5 is 4 twisted pairs of cable, 3 taken up by the map sensor which leaves 5 left for temp sensors.

i made a cheapo cardboard box arduino to sit in and fitted it in a space behind the instrument cluster

Wired up

Wired up by

Muzza1742, on Flickr

Cardboard box

Cardboard box by

Muzza1742, on Flickr

The wiring diagram for the boost circuit can be found here:

http://blog.nsfabrication.com/2009/06/29/arduino-based-lcd-boost-gauge-with-resettable-peak-hold/

mines got more wires in than that but its also set up for some other sensors i wanna install at a later date.

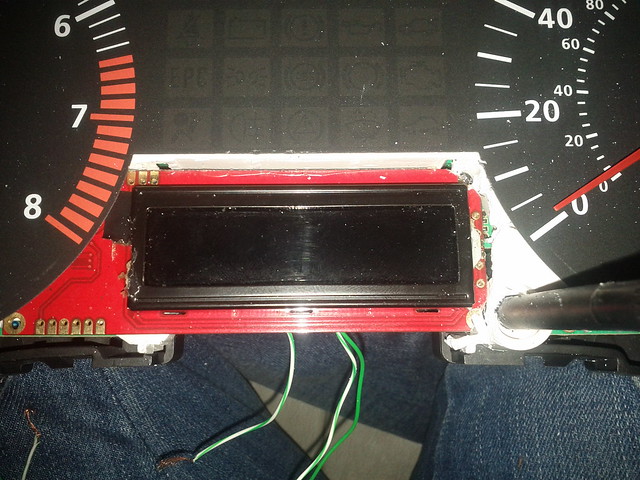

If you look through the earlier posts you can see how i cut up the clocks to fit in the lcd. i had to chop out lots of plastic because i brought the serial lcd instead of the parallel one ive listed above. the serial one literally just fits - its touching the oem clock on the right hand side and if i took anymore out on the left hand side the mileage reset button on the clocks would fall out .

The trade off is that the serial one only needs 3 wires 0v/+5v/signal and the parallel need around 9 wires.

Power can be supplied from the back of the stereo for a ground and switched live. The arduino is ok with being supplied with 12v but the be safe i ripped apart an old usb car charger and hardwired it into the circuit so i get a nice even 5v @ 1A.

i cant think of anything else ive missed but its late and im tired, so if anyone wants any more info please just ask.

The codes set up to start the serial interface, pause 1 second, display the splash screen for 4 seconds then show the current boost and peak boost

It also contains my workings out for the temp gauge and some stuff i was doing with a light dependent resistor thats now useless