Little update....

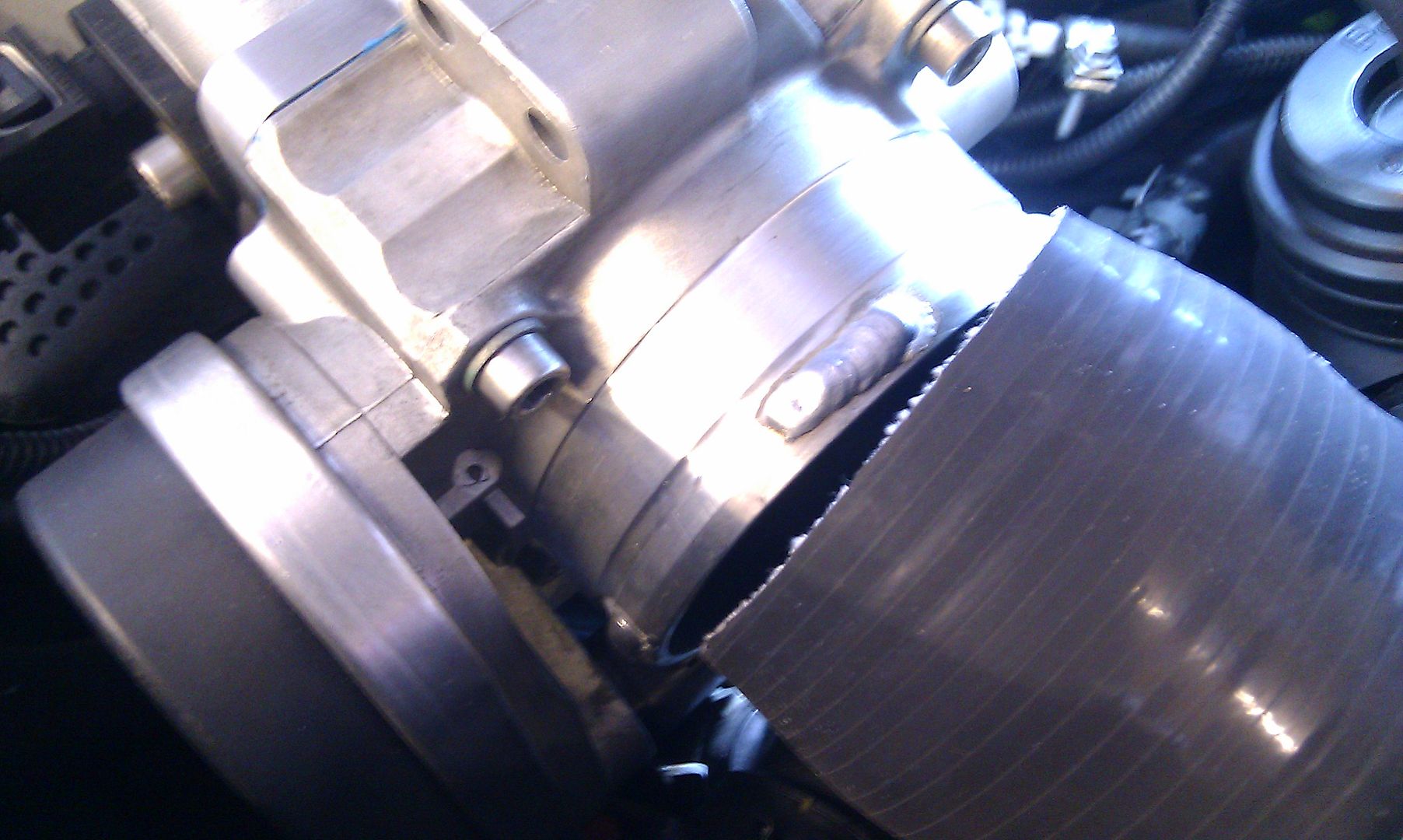

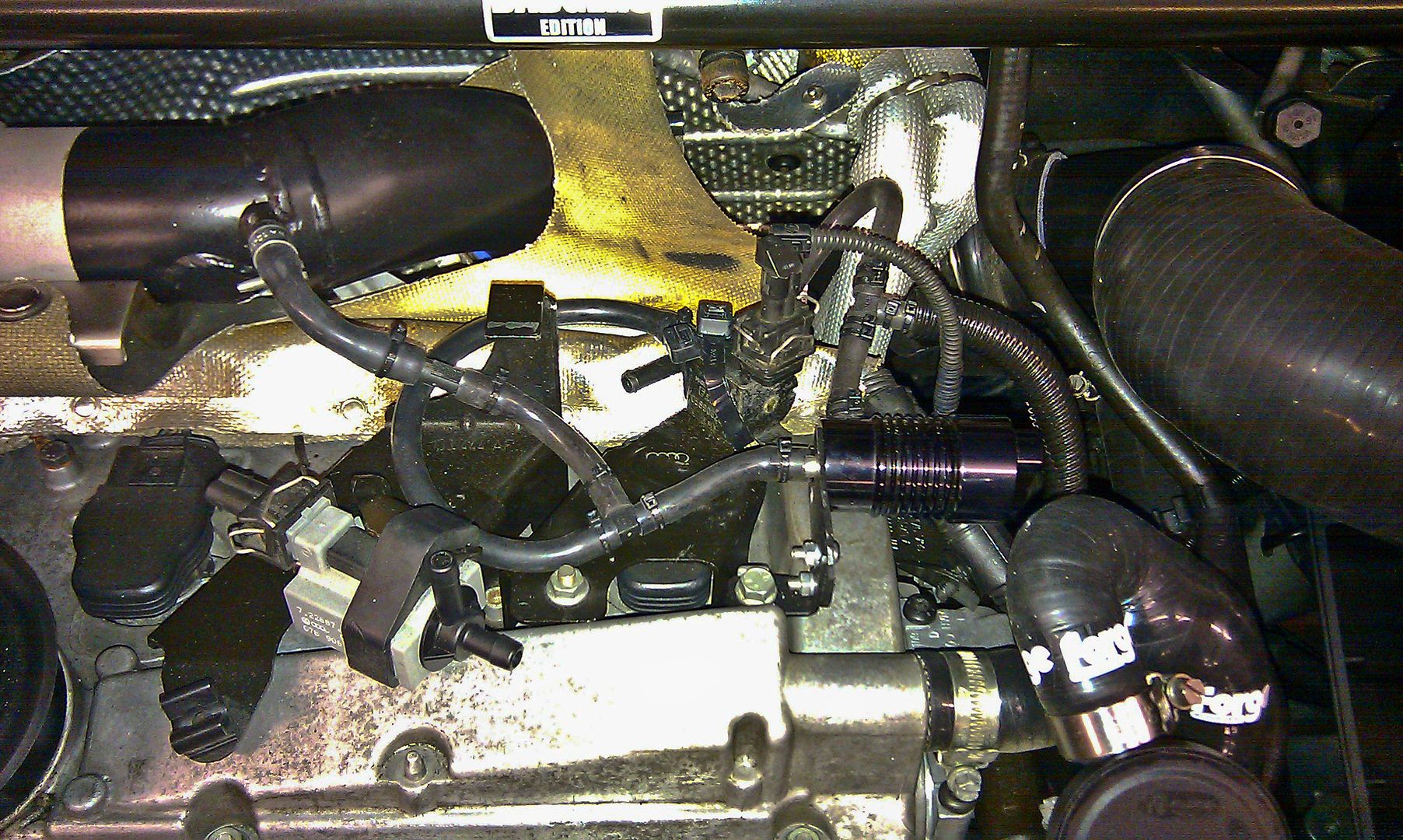

After popping the throttle body hose for the second time (at low boost) in a country lane in the middle of the night I asked Bill to weld some beads onto the throttle body to stop this happening again... R32 TB's don't have the bead around the edge like the std 60mm TB as its not a turbo car... lack of a bead for the hose/clamp to sit up against is the main contributor to hoses popping off...

Thanks mate :thumbsup:

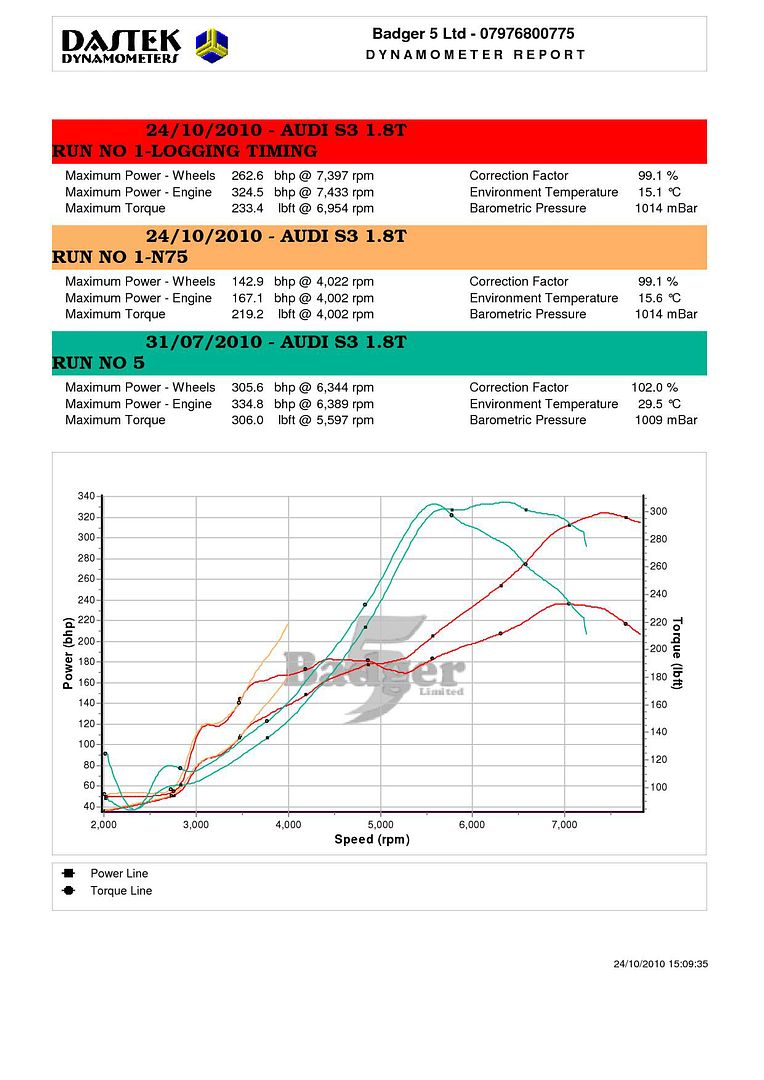

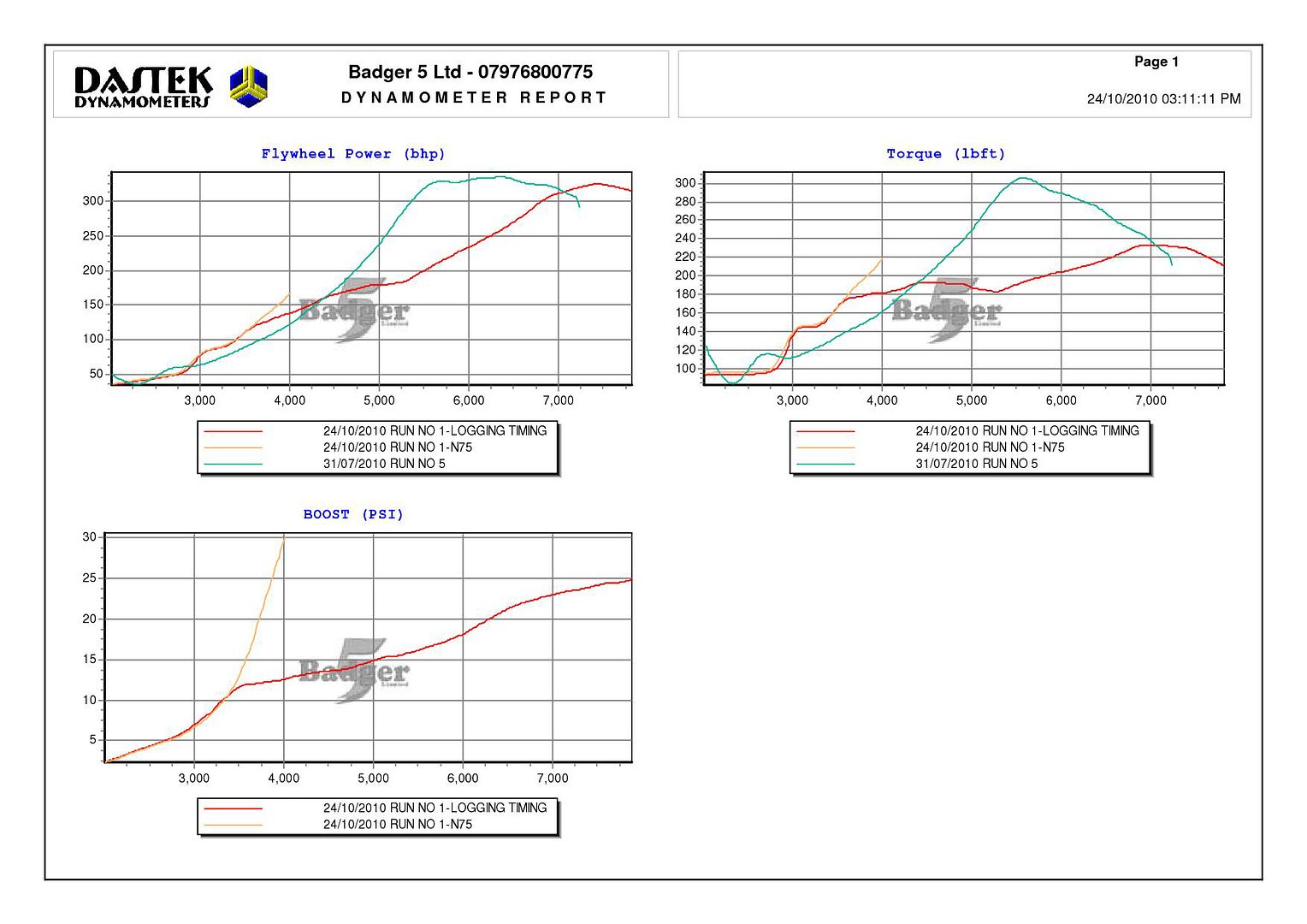

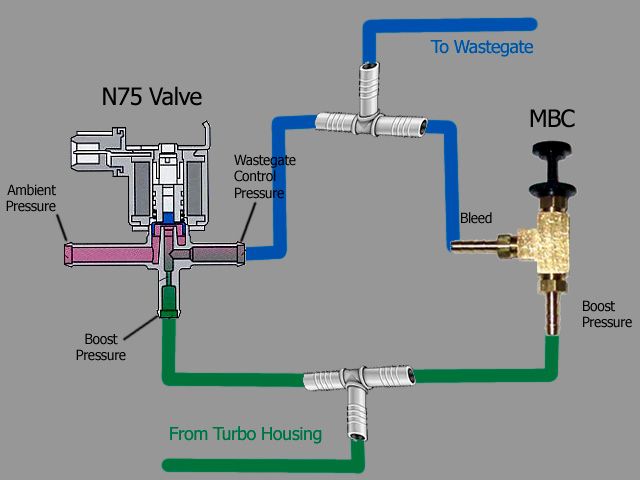

While Bill was happy in TIG land fabricating bits for a GT30 powered Mk2 Golf, I got my car on the dyno to take a few logs and see where the N75 was in the grand scheme of things as I want to use the N75 again albeit in parallel with the MBC... part throttle with MBC's is a little erratic at times and I want to see if I can sort that...

I have found a page where someone uses an N75 normally but uses a switch on WOT (wide open throttle) to switch an N249 valve into re-routing boost control from the N75 to the MBC... this way you get ECU control over boost when driving normally and MBC boost sustainability under WOT

The link is here:

MBC/N75 Boost Control results - NewBeetle.org Forums

I may well have a go at this at some point...

Anyhoo.... operating a car on a dyno is a very unnatural experience... first thing I wanted to do is release the handbrake (which is left on while the car is on the dyno) and then once I started off in first gear I wanted to put my seat belt on!!!... lol!

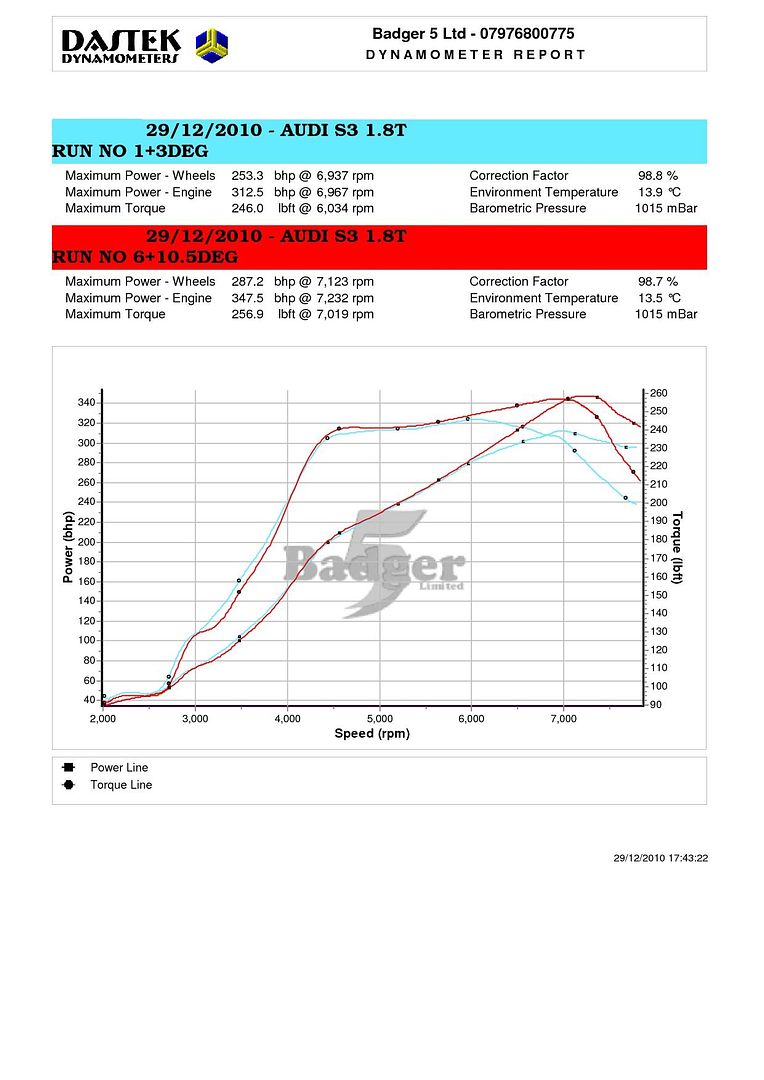

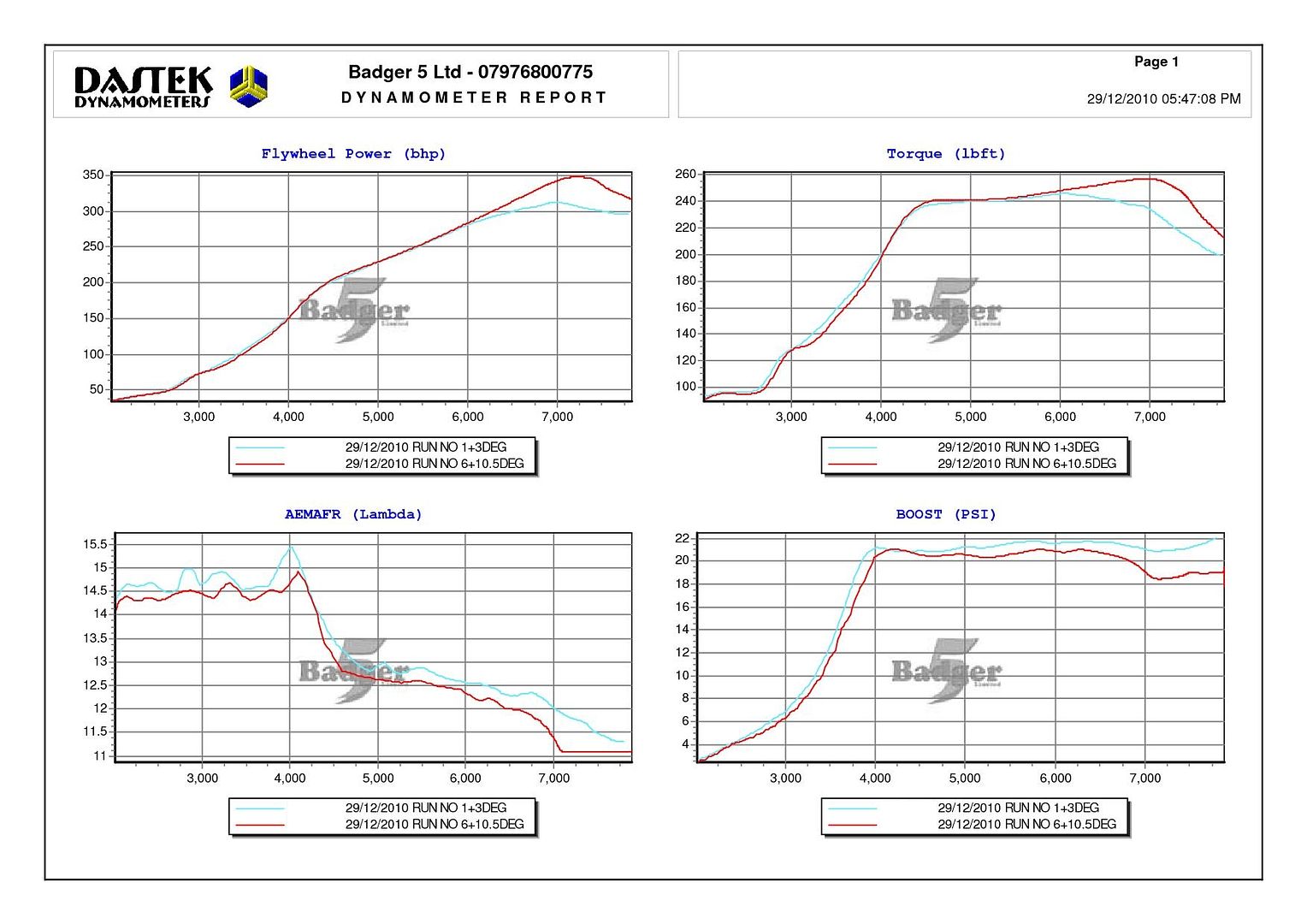

Did a couple of runs on actuator pressure... pretty evident I am getting bad boost creep as the internal gate is now far to restrictive for all the extra flow the charge system and head now provide... its a 1 bar actuator but with preload starts opening about 0.8 bar... boost then creeps up to over 24psi at over 7k rpm... this will be manageable once the mapping is sorted as this will be around the boost I will end up running but not the best thing that could happen... Basically it means I have to have the head off again and either port the crap out of the internal gate (as Bill did to Welly's) or go external gate as my manifold supports this... I am of course going external gate as I want to do it right, first time...

I did a couple of runs logging timing pull etc (there was no timing pull at all) and AFR was far too rich killing any hope of power higher up the rev range... I didn't run the car today to see what power I had anyway but its pretty evident there is some work to do as the current map is way out...

Last run I did was to see what the N75 was up to.... I pulled out about 4k rpm as the boost hit 33psi!!!!... N75 is now unplugged

After the runs I pulled the graphs together including one from before I fitted the large port head etc...

The red lines are the current setup with actuator (and boost creep) pressure only... running my previous map etc... the teal coloured lines are from my previous setup with the unmodded FMIC and charge pipes + small port head.... the orange lines are from the aborted run with the N75 connected... I have included this as you can see the potential the engine now has once I throw some boost at it...

In the second pic you can see where the boost was heading before I aborted (orange line) and the boost creep (red line)... I didn't log boost on the runs before the large port but was running about 1.5bar at the time..

The interesting thing is I am potentially getting full boost (1.6bar) well under 4k rpm, which (from memory) is much earlier than before... also when you compare the power lines from before (teal) to now (red and orange) everything is happening much earlier in the rev range than before....

Thats about it for now... got a bit of work to do but she is showing potential for plenty of power

<tuffty/>