No probs my friend... I think the code is posted elsewhere in SCN but as they said it was ok to do so, I did... every little helps

<tuffty/>

<tuffty/>

Last edited:

Hi Paul,

Will be keeping on eye on how this turbo spools - nice test bed to see if it's going to be suitable for my golf up there

Gary

And you have, well done.WILL have the rods in this weekend if it kills me

<tuffty/>

And you have, well done.

well done mate,i bet the old hamstrings are a bit tight this evening

looking good not bad for a weekend

when my mate did his BT on his s3 his ko4 turbo and manifold were cracked on inspection other than that he never heard it blowing and it never missed a beat

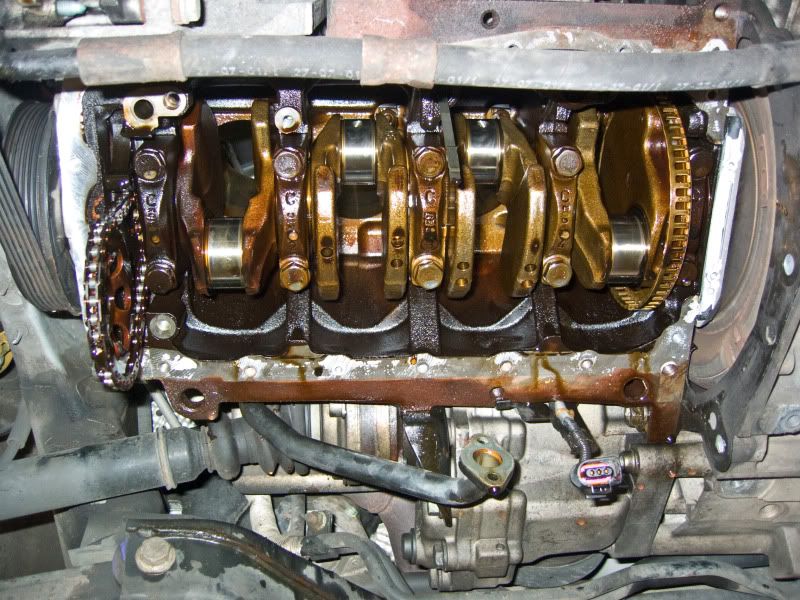

Thanks mate, was determined to get them in... the state of the parts I took off (no thanks to Audi Variable Servicing!!) slowed me a tad but the pistons cleaned up nice and went together well.

My shoulders and neck have been hit the most... getting used to using a ramp now... gonna come hard when I return to axle stands outside the house ;P

Thanks, only built one engine before this and that was nearly 20 years ago (2ltr pinto for a Mk2 Escort)... this is a bit different with the amount of stuff you have to remove to get anywhere and its still in the car.

The mani looks like it has a crack but like your mates, mine never blew and ran as sweet as a nut... rest of the turbo looks ok, I have given the shaft it a quick twiddle and there is no excessive play (not that it burnt oil anyway) and taken some pics but not really looked at them any furtheras yet.

Hopefully it will all be good for selling on.

<tuffty/>

Didn't spend ages working on the car tonight, removed oil and water pipes plus EGT sensor, fitted the charge pipe brackets and charge pipe to Bills other engine ready for the various pipes to be fabricated.

Managed to get the cat off but the DP is proving to be a bit of a pig... Seems I have 2 choices, drop the subframe or cut the DP in half... found this article that goes on about both methods...

http://forums.fourtitude.com/zerothread?id=2783203&page=5

Will have a chat with Bill tomorrow

<tuffty/>

I've removed the same downpipe from a lcr with no problems. Cut off the fixing leg thats inserted into the rubber mount, slide the downpipe off the turbo studs and pull the downpipe up and out. no need to cut it up or drop the subframe unless you want too.

Sure, Bill has a honing tool that fits in a drill...

http://www.lasertools.co.uk/item.aspx?item=640

<tuffty/>

How do you keep the crap off the crank etc?