-

Welcome to our new sponsor Lecatona, a brand dedicated to enhancing performance for VAG group sports cars, including SEAT, Audi, Volkswagen and Škoda. Specializing in High Pressure Fuel Pump (HPFP) upgrades.

-

The forums will be offline for maintenance on Friday 15th November at 10pm for up to an hour. Thank you for your patience.

Dan's GTX3582r, 2.0 20v, project '600'

- Thread starter Dan1720v

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some spot on work going on there.

Looks like it will be hard work to keep full control on the tarmac but good fun i should think.

Looks like it will be hard work to keep full control on the tarmac but good fun i should think.

Bit more of an update.

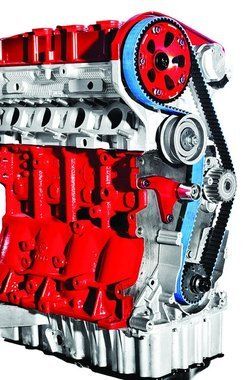

Car is back from having a full 3" exhaust fitted. And the cams have turned up from Badger5. Only waiting on the solid lifters and then the engine can be assembled.

Cylinder head is being done by a local machine shop, having all new supertech guides done, very light skim and a dip.

Car is back from having a full 3" exhaust fitted. And the cams have turned up from Badger5. Only waiting on the solid lifters and then the engine can be assembled.

Cylinder head is being done by a local machine shop, having all new supertech guides done, very light skim and a dip.

Updates..

Should update this really, bottom end built, head back from having the solid lifters Lash caps machined. Sump arrived from forge. Just waiting on the manual tensioner and ARP camshaft bolt from Integrated engineering, and a new cam chain tensioner.

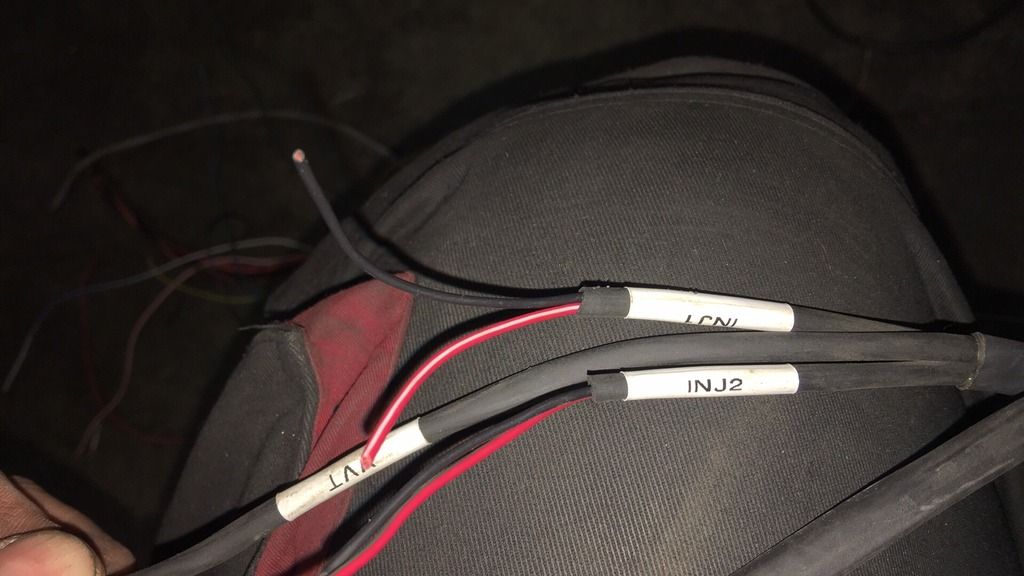

Box of electrical bits turned up from simtek, stuff like heat shrink, plugs, and a Neptune connector to do a bulkhead break point.

Currently debating ripping out the loom and rewiring the whole car from scratch with a modular fuse box.

It'll be track days over the next few next few months/next year. Shake it down in 2wd form, then 4wd it over winter next year. Then compete.

Just had a message from Bill saying my manual tensioner has arrived along with the ARP cam bolt. Water pump and Cambelt arrived this week from TPS, Just waiting on the cam chain tensioner now!

Just had a message from Bill saying my manual tensioner has arrived along with the ARP cam bolt. Water pump and Cambelt arrived this week from TPS, Just waiting on the cam chain tensioner now!

Well @Stopherson came up a few weeks back to Give me a hand and to get his MOT done. So we cracked on with the cup.

No pictures taken, but the subframe got welded up a bit more substantially this time, so no cracking! Then we set about getting the new engine in. And these are the only 2 pics for the day lol.

I've bought a pipe bender and some pipe to attempt hard piping the intercooler, but it just seems to want to kink no matter what I do tried the usually compacting with sand but it didn't work.

tried the usually compacting with sand but it didn't work.

Gear Cables are off at speedy cables to be made longer, other than that it's wiring and fluid systems and we're Ready to go![/QUOTE]

No pictures taken, but the subframe got welded up a bit more substantially this time, so no cracking! Then we set about getting the new engine in. And these are the only 2 pics for the day lol.

I've bought a pipe bender and some pipe to attempt hard piping the intercooler, but it just seems to want to kink no matter what I do

Gear Cables are off at speedy cables to be made longer, other than that it's wiring and fluid systems and we're Ready to go![/QUOTE]

Nice update.

Looks like you have found a great spot for the air filter as well especially if your having some sort of air catch or vent but even still its a good spot.

Hopefully your have a little more luck with the pipe bending soon.

I assume your going for alloy pipe which i guess would explain the kinking.

do you not have access to a tig welder that way you can buy the shapes and weld them together with the odd silicone join for flex. Im sure with a build like this you have already thought about this though.

Looks like you have found a great spot for the air filter as well especially if your having some sort of air catch or vent but even still its a good spot.

Hopefully your have a little more luck with the pipe bending soon.

I assume your going for alloy pipe which i guess would explain the kinking.

do you not have access to a tig welder that way you can buy the shapes and weld them together with the odd silicone join for flex. Im sure with a build like this you have already thought about this though.

Yeh I have, I can't tig myself, so was trying to cheat lol.

The scuttle is actually the place the group N and Group A rally cars took their air intake from so I'd expect it to have decent enough flow. Time will tell!

The scuttle is actually the place the group N and Group A rally cars took their air intake from so I'd expect it to have decent enough flow. Time will tell!

Bit more done.

Centre console, in pictures it does look very high, but I can't seem to get an angle that actually portrays where it is. It's a bit higher than I planned, but sadly handbrake functionality denoted it was this high. It's inlu actually about an inch higher than the centre of the wheel.

Brake and clutch reservoirs fit nicely inside.

Switch panel (not finished, needs the sides welding on but we ran out of time today)

I've also sorted a panel for the swirl pot and fuel pump, and a checker plate floor pan to cover the master cylinders.

Centre console, in pictures it does look very high, but I can't seem to get an angle that actually portrays where it is. It's a bit higher than I planned, but sadly handbrake functionality denoted it was this high. It's inlu actually about an inch higher than the centre of the wheel.

Brake and clutch reservoirs fit nicely inside.

Switch panel (not finished, needs the sides welding on but we ran out of time today)

I've also sorted a panel for the swirl pot and fuel pump, and a checker plate floor pan to cover the master cylinders.

Nah it's actually nowhere near that high, it's only 1" over the steering wheel centre. Does give a really nice feel for shifting.

Nice update, function over form i guess with the height & i bet it will feel nice when shifting.

Nah it's actually nowhere near that high, it's only 1" over the steering wheel centre. Does give a really nice feel for shifting.

That doesnt sound as bad then i guess its the picture making it look really high.

Nice and convenient from the steering wheel and shifter and as your be shifting so much your need them close together.

Mega update I guess!!

It'll be very brief as I haven't got many pics.

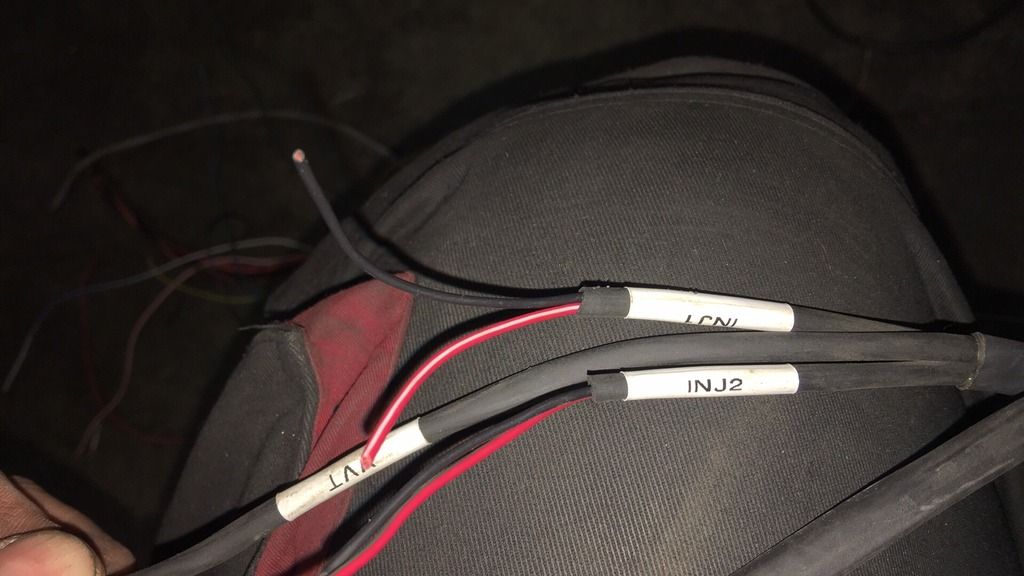

Engine was in, then I set about wiring:

Then did the interior loom (no pics) but did set it up so I can have mains only (just as a 'I'm coming' setting on track after having a few near misses with people underestimating my approach speed.

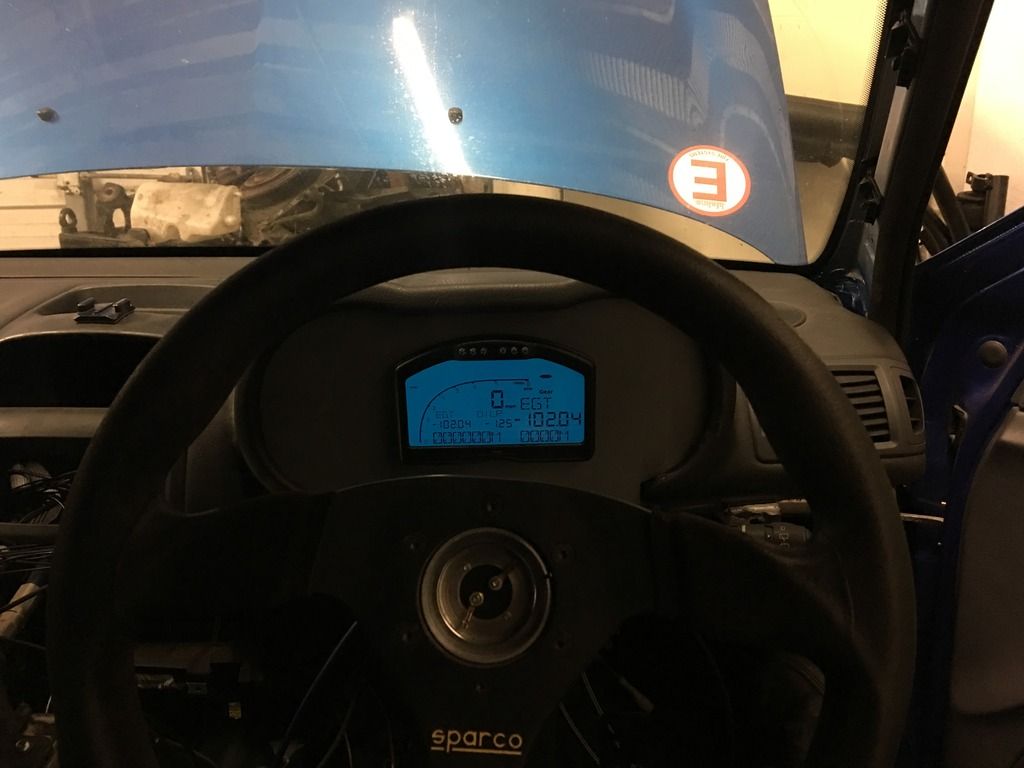

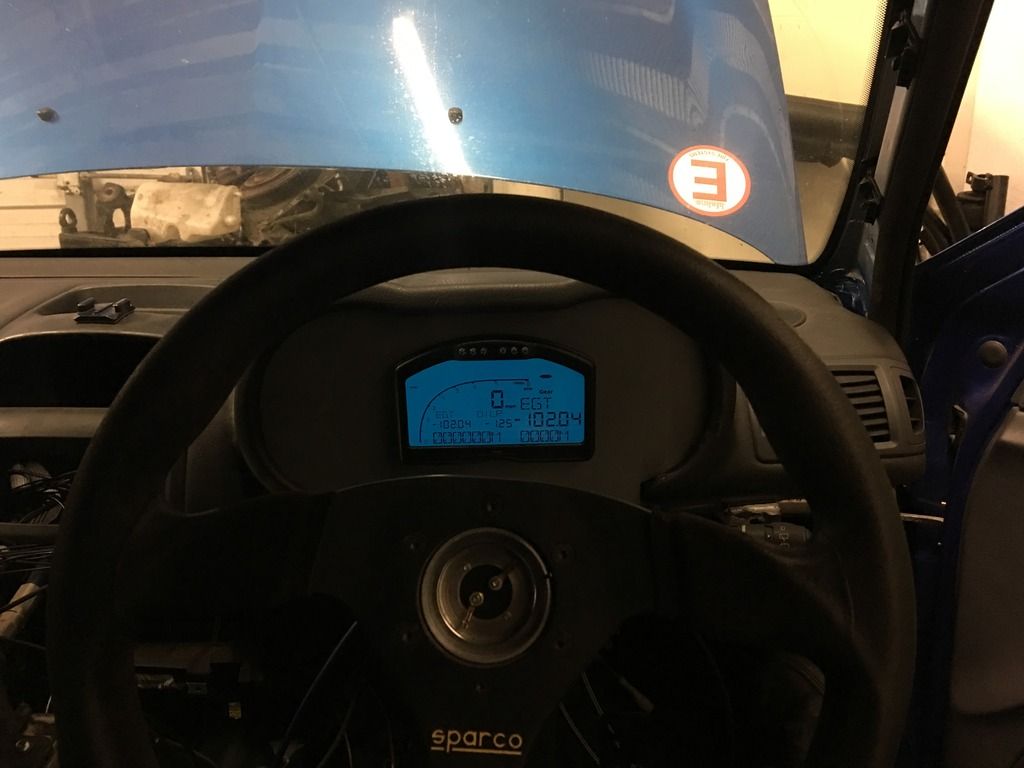

DASH2 wired up and functional.

Total weight.

Then it was onto running in and mapping. Unfortunately this didn't go to plan.

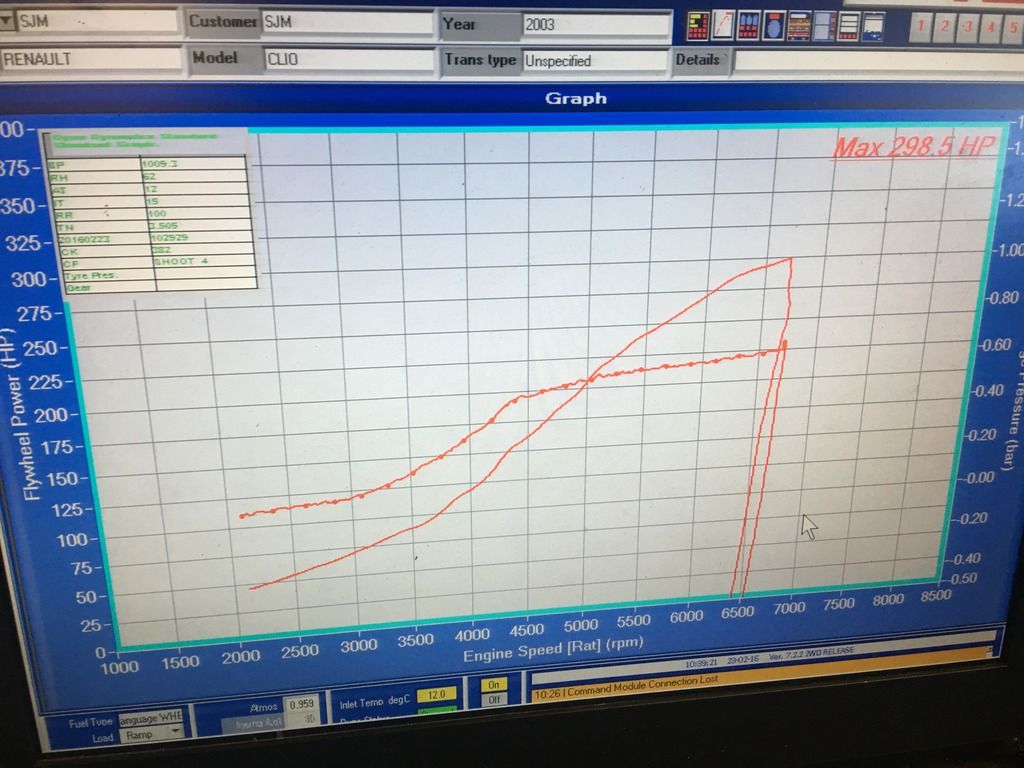

After running in and an oil change I started doing the low end mapping. This all went well. Decided to try a couple of gate pressure runs. First pull with a footballer map (rich and retarded) did 249 at 0.6bar peak. Tweaked the fuel table and started another in which I noticed a rattle on the way up so immediately killed the ignition and got out to investigate.

With the Fuchs Titan race pro being red, the dyno cell looked like a murder scene. Nice spray mark right up the wall. And about 3L on the floor. ****. Set about investigation as to what had failed. Then noticed the oil filter had pulled off on 1 side. (This would explain the lack of oil pressure lights!) as it was still pumping but not enough pressure to sustain clearance from 3krpm. But why had this happened? Well, turns out the local Audi specialists parts lady had given me the wrong part. It was too small to notice the thread was different (M18 against 3/4unf.) - about 1mm difference, which would explain why I didn't notice it. So in urgency I popped over to the local factors and found the cheapest m18 oil filter I could. Just so I could start it and see if the motor had survived. It had thank god. But I called it a day to pull the sump off and inspect, rather safe than sorry! Upon inspection all the shells were scrap. However the crank was unharmed.

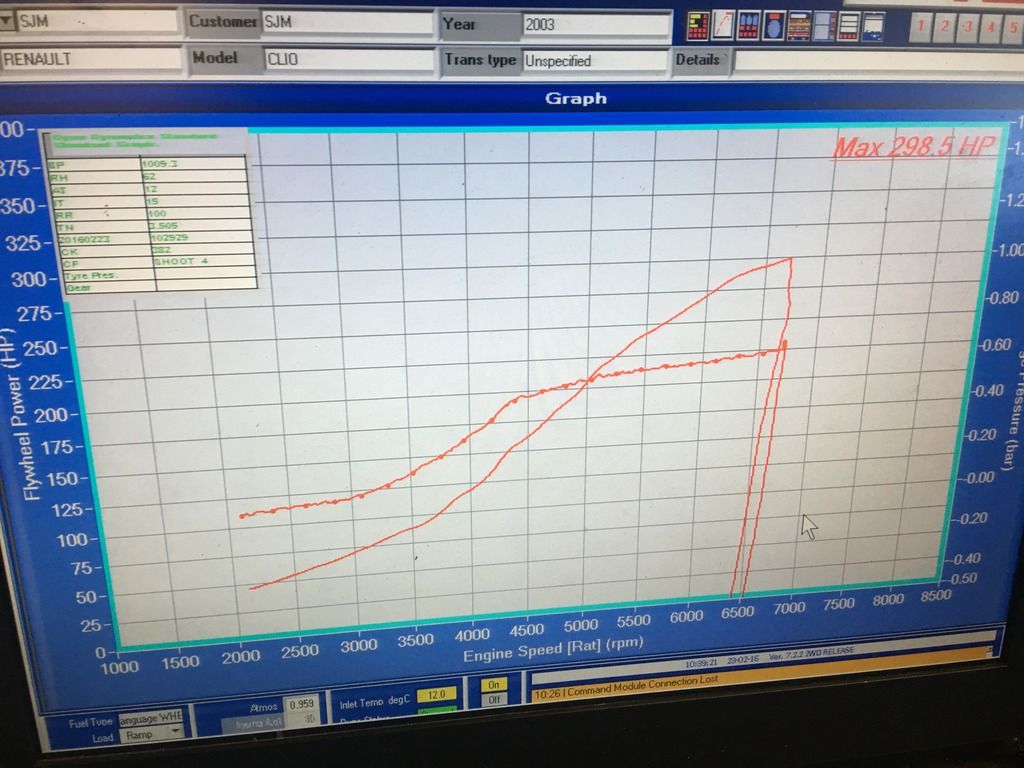

Then managed to get a set of mains and big ends of King racing bearings from TSR. Fitted them and have done about 50 road miles with it. All seemed well so booked the dyno again. Took it up to the dyno and started doing the mapping again. Did a base run that came out at 246, then added 3 degrees of timing, 269, then another 3 and got 304. Cleared the screen and went to get another run. This time 298. But noticed a rattle. Argh!!! This time it was box related. Pulled the end cap off the box to be greeted by a snapped circlip. Well atleast it was an easy fix. Hopefully!! Circlip a due tomorrow AM.

Here's a pic of the power graph. Happy with that at 0.6bar!

It'll be very brief as I haven't got many pics.

Engine was in, then I set about wiring:

Then did the interior loom (no pics) but did set it up so I can have mains only (just as a 'I'm coming' setting on track after having a few near misses with people underestimating my approach speed.

DASH2 wired up and functional.

Total weight.

Then it was onto running in and mapping. Unfortunately this didn't go to plan.

After running in and an oil change I started doing the low end mapping. This all went well. Decided to try a couple of gate pressure runs. First pull with a footballer map (rich and retarded) did 249 at 0.6bar peak. Tweaked the fuel table and started another in which I noticed a rattle on the way up so immediately killed the ignition and got out to investigate.

With the Fuchs Titan race pro being red, the dyno cell looked like a murder scene. Nice spray mark right up the wall. And about 3L on the floor. ****. Set about investigation as to what had failed. Then noticed the oil filter had pulled off on 1 side. (This would explain the lack of oil pressure lights!) as it was still pumping but not enough pressure to sustain clearance from 3krpm. But why had this happened? Well, turns out the local Audi specialists parts lady had given me the wrong part. It was too small to notice the thread was different (M18 against 3/4unf.) - about 1mm difference, which would explain why I didn't notice it. So in urgency I popped over to the local factors and found the cheapest m18 oil filter I could. Just so I could start it and see if the motor had survived. It had thank god. But I called it a day to pull the sump off and inspect, rather safe than sorry! Upon inspection all the shells were scrap. However the crank was unharmed.

Then managed to get a set of mains and big ends of King racing bearings from TSR. Fitted them and have done about 50 road miles with it. All seemed well so booked the dyno again. Took it up to the dyno and started doing the mapping again. Did a base run that came out at 246, then added 3 degrees of timing, 269, then another 3 and got 304. Cleared the screen and went to get another run. This time 298. But noticed a rattle. Argh!!! This time it was box related. Pulled the end cap off the box to be greeted by a snapped circlip. Well atleast it was an easy fix. Hopefully!! Circlip a due tomorrow AM.

Here's a pic of the power graph. Happy with that at 0.6bar!

Running 1 bar of boost now, still on a 'footballer' map (mappers term - rich and retarded) so plenty of power to come yet.

Had an outing at Combe, where the aux belt failed causing a drop in voltage to the coils which caused a misfire and brought me in.

On board;

http://youtu.be/fV-S54YL5Ek

Fly by

Had an outing at Combe, where the aux belt failed causing a drop in voltage to the coils which caused a misfire and brought me in.

On board;

http://youtu.be/fV-S54YL5Ek

Fly by