More of the little jobs done this weekend..

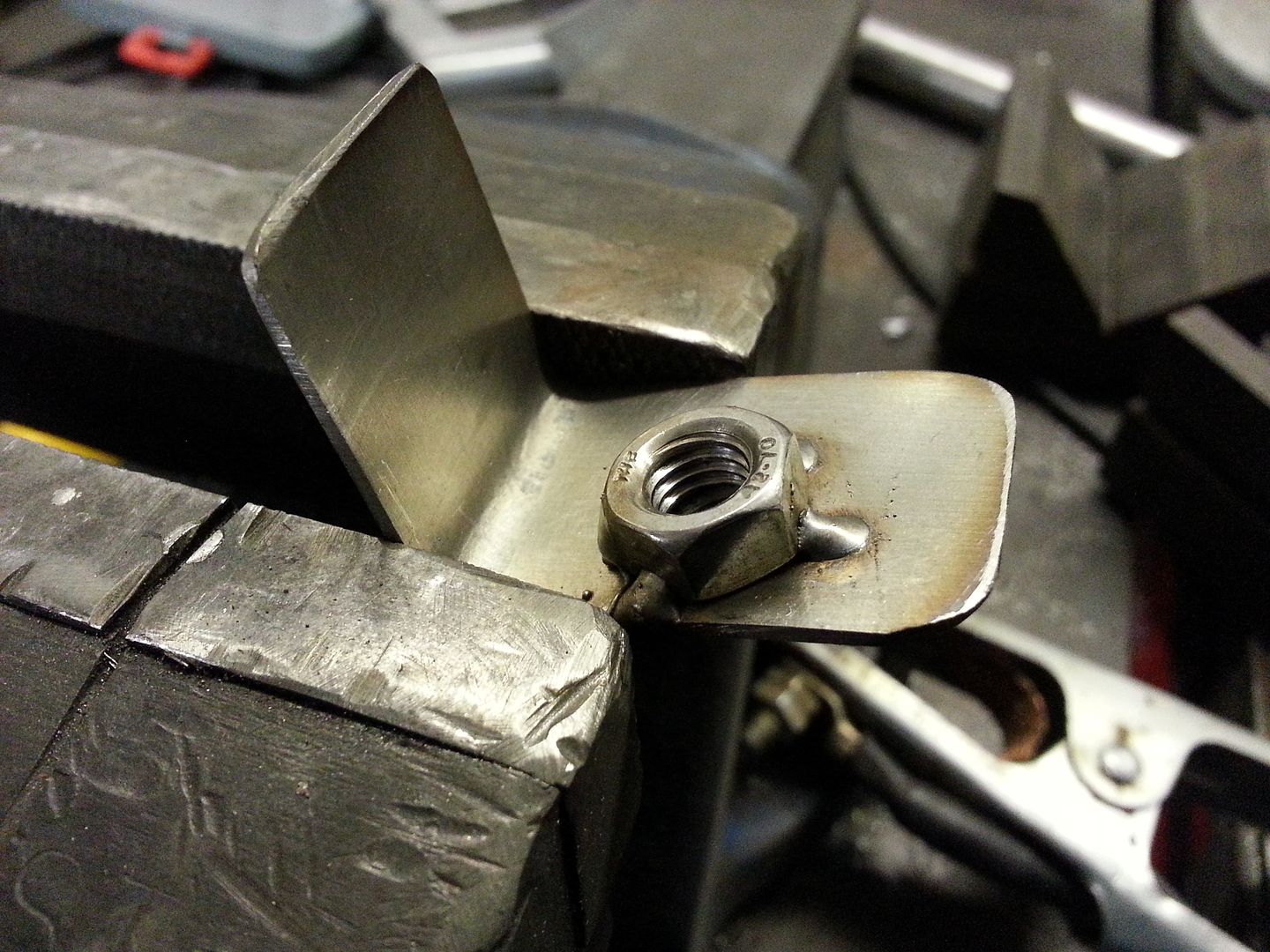

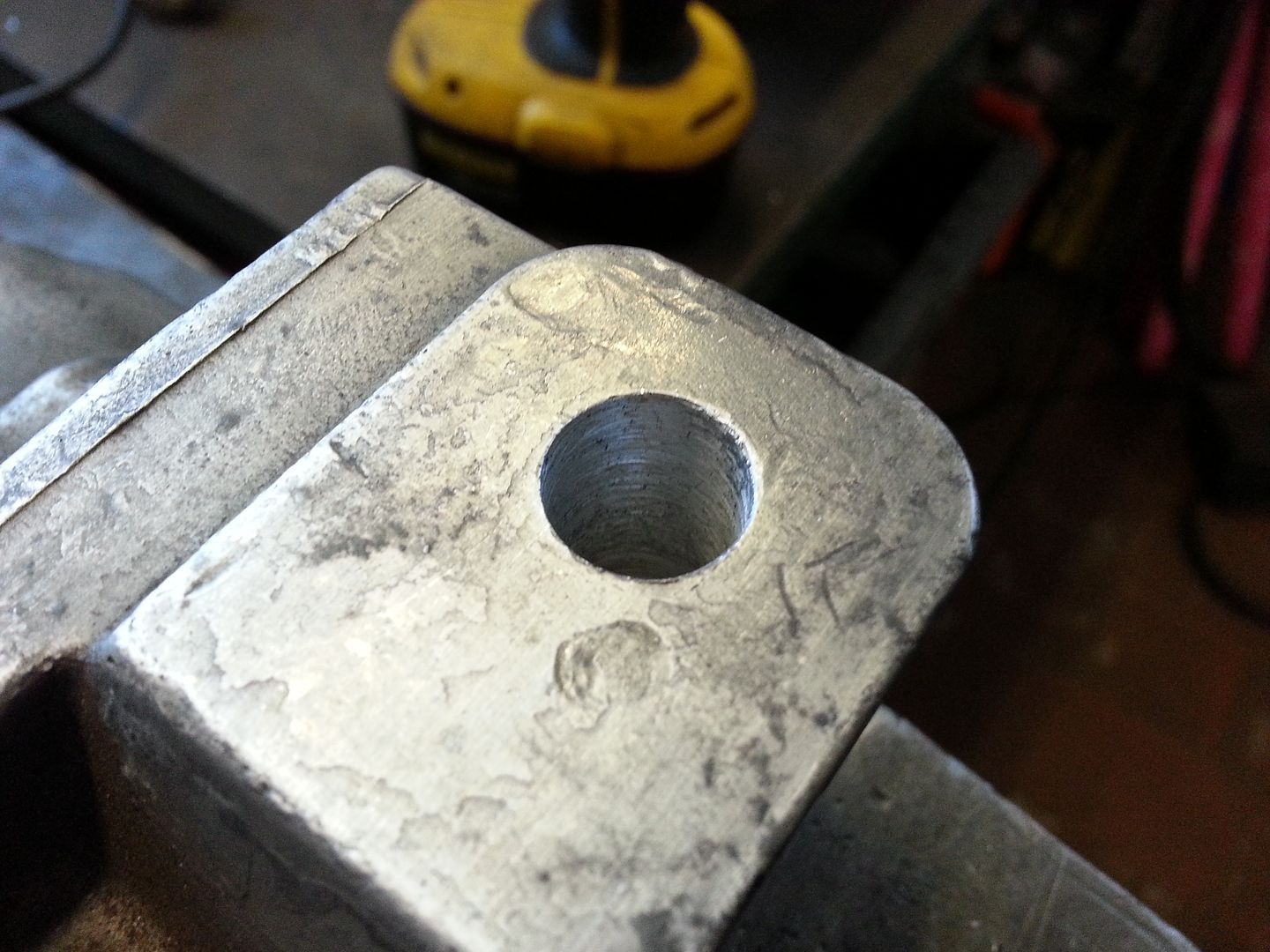

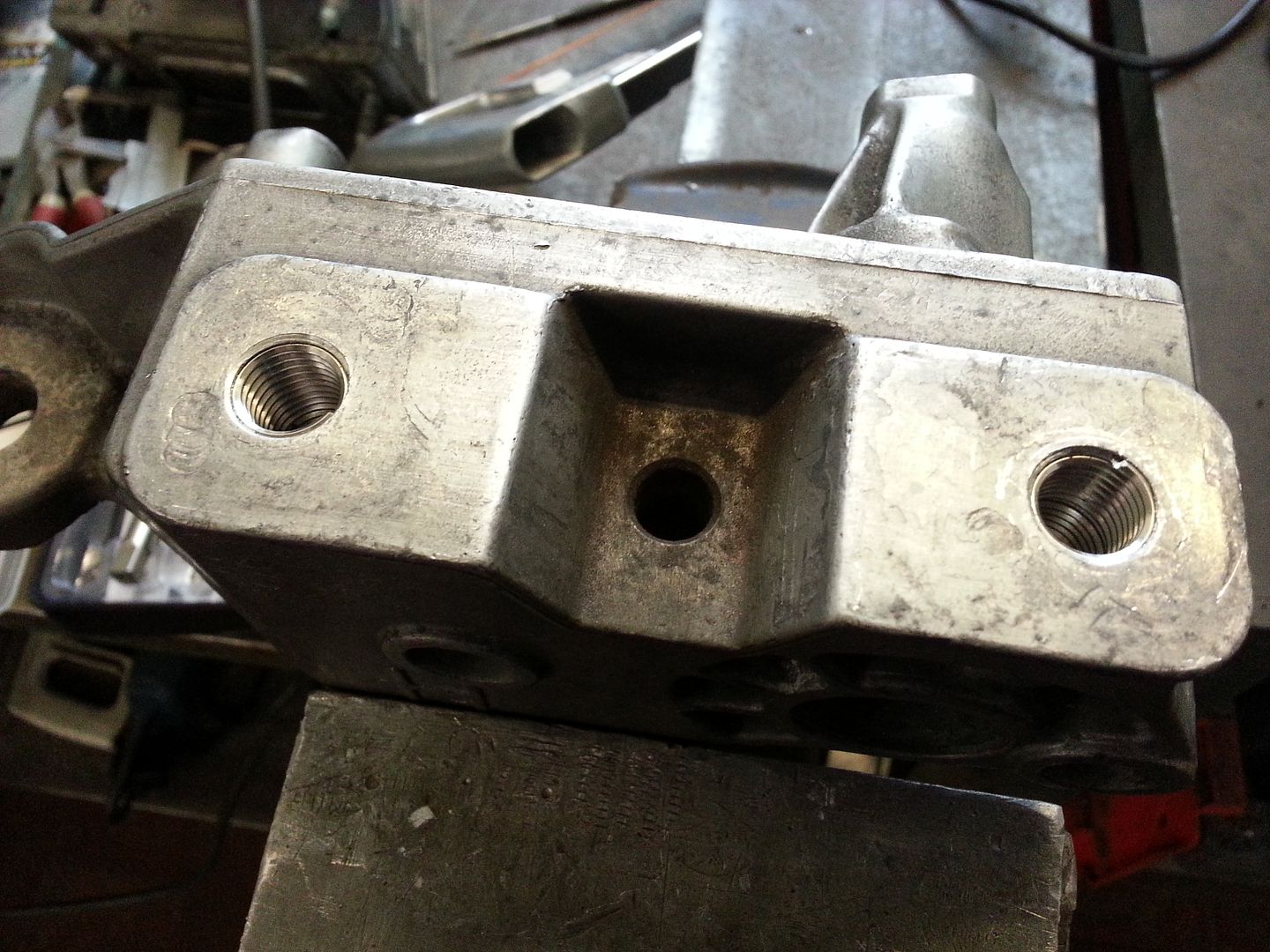

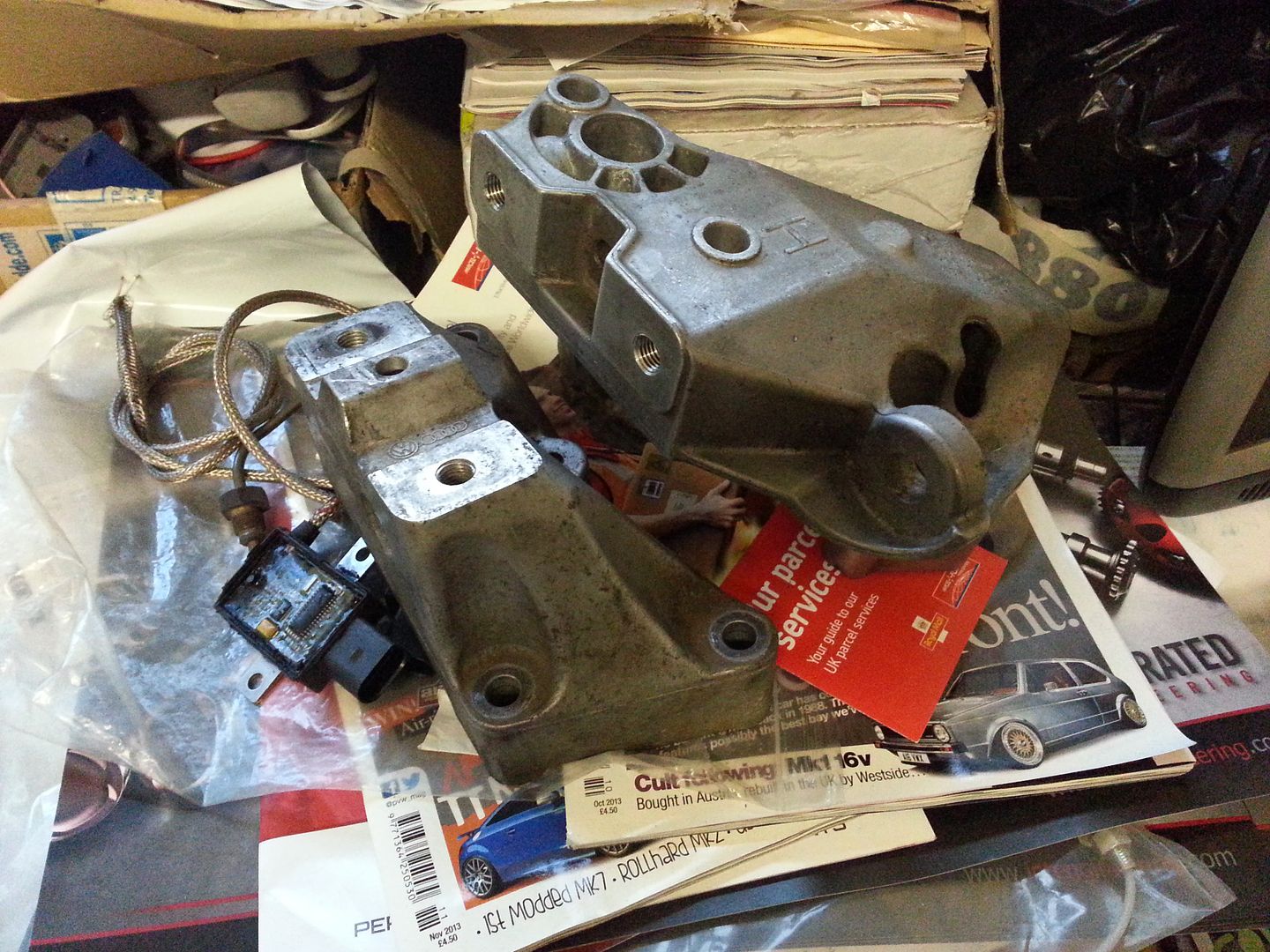

The threads in the engine mount (the crappy one that gets in the way of cam belt changes) were pretty much non existent... in fairness its been off a few times and the threads don't seem to last more than a couple of belt changes before showing signs of failing...

So bought a helicoil kit and set about sorting it...

Drilled out the holes

Tapped then with the supplied tap...

...and screwed in a couple of helicoils (they were 16.5mmm deep so used two for better thread contact on bolt)

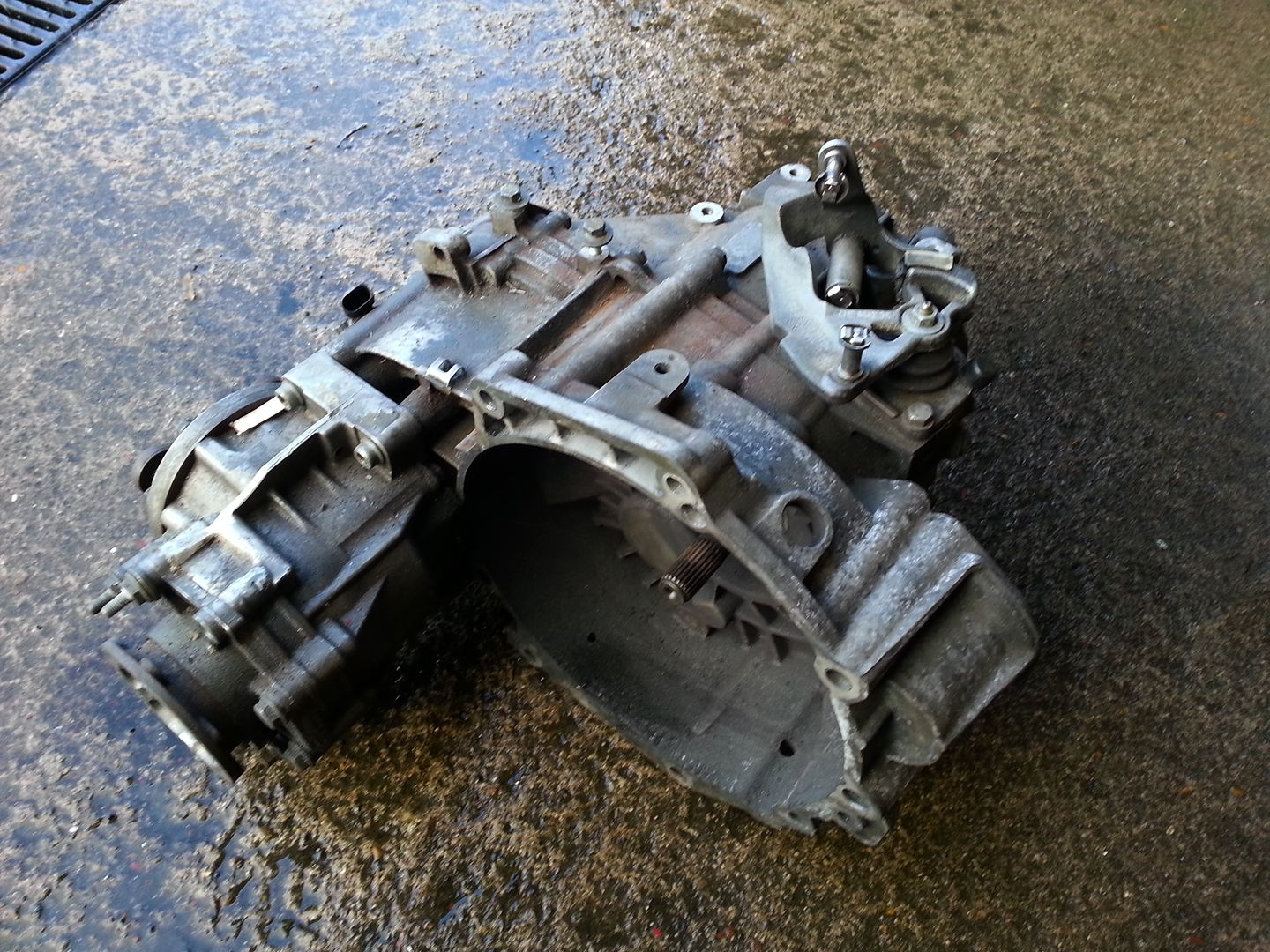

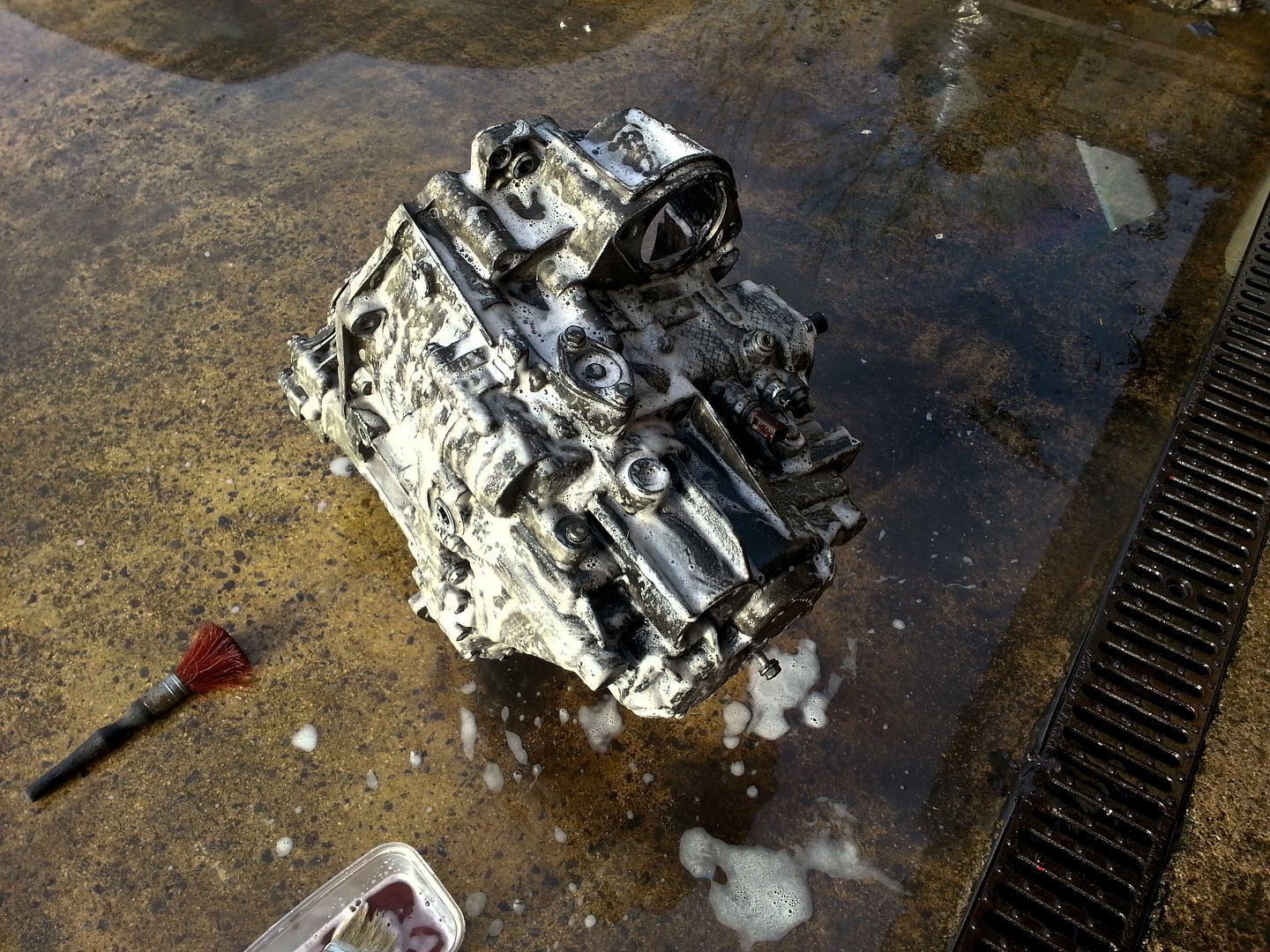

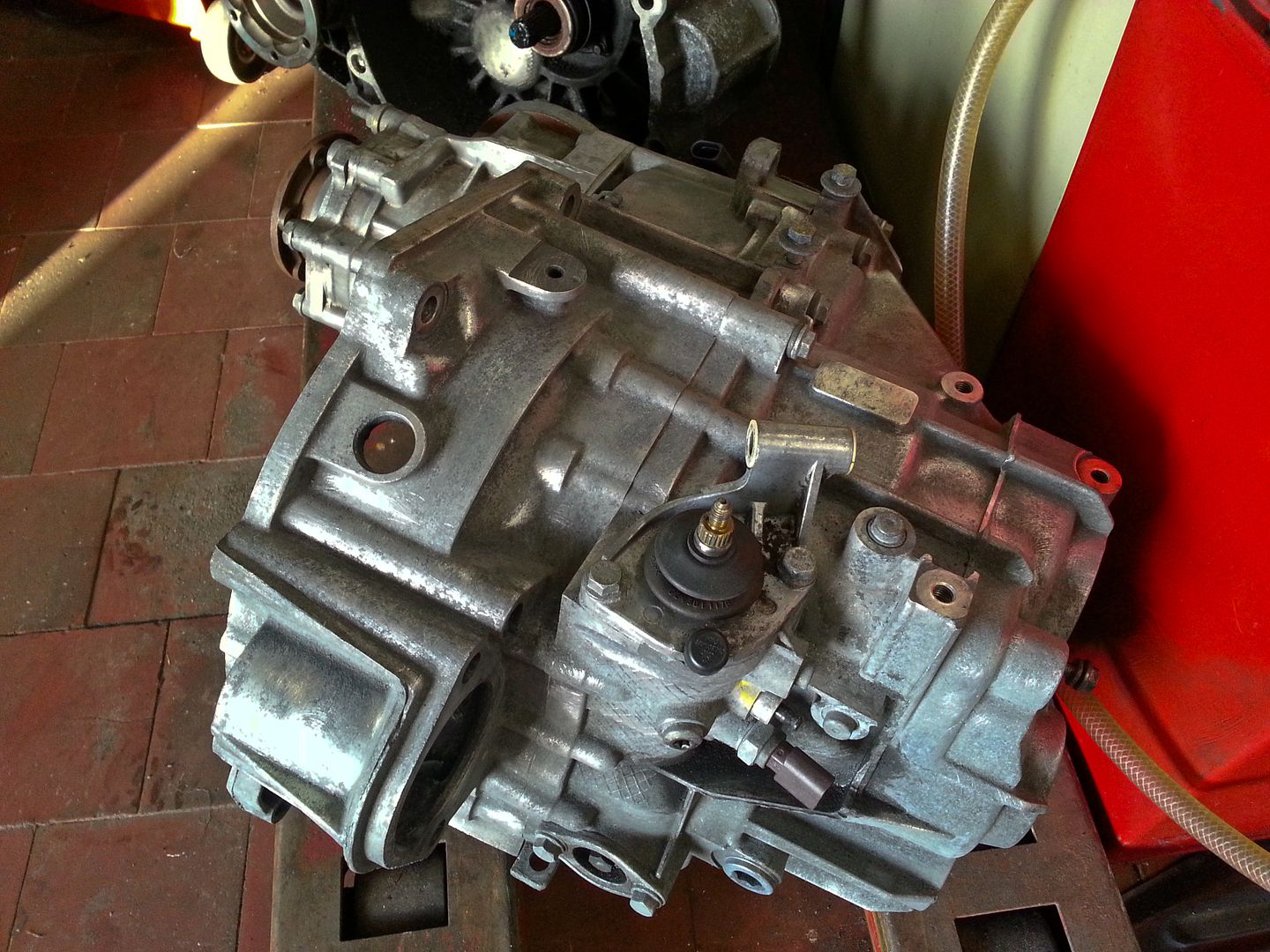

Next I removed my gearbox from the the build engine for cleaning...

Gave it a good going over with a water based detergent, stiff brush and a scotch brite pad then power washed it...

Finished off with a wire brush... not 'clean' but paintable at least...

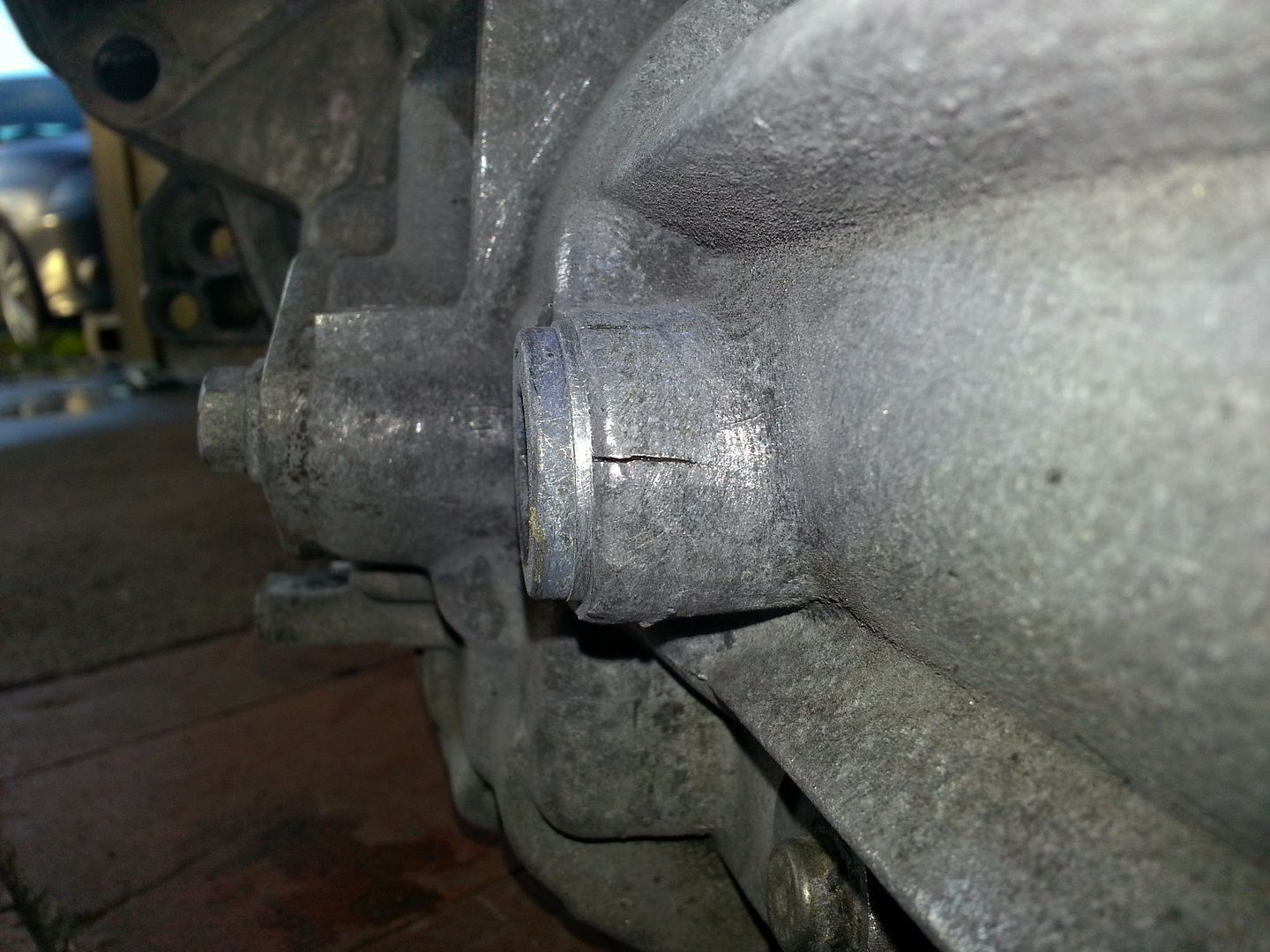

Unfortunately I spotted a small issue... there were a couple of small cracks on the oil filler boss

I think this could be due to the filler plugs being metal rather than the later ones which are plastic and there has been some sort of reaction or expansion that has caused this damage to occur... just as well I am planning on rebuilding another box then really... I have a low mileage (40k) 02m FWD box from a Leon that I will use the internals of to build a quatty box...

Bill has a broken 02M quatty box (selector fork and a dodgy syncro)... Hoping this might be available as a donor for the build...

That won't be for a little while yet though as I want the car up and running first...

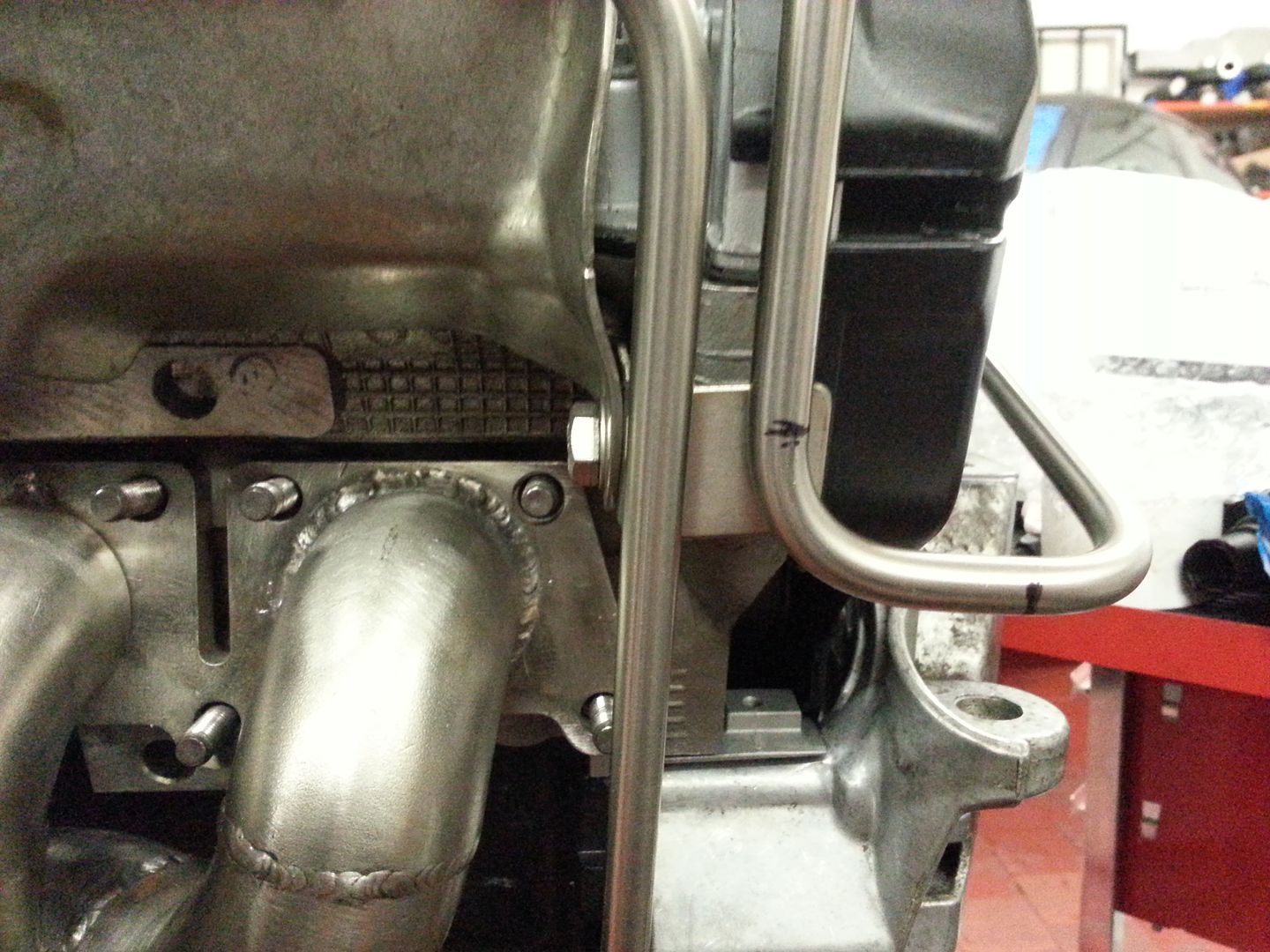

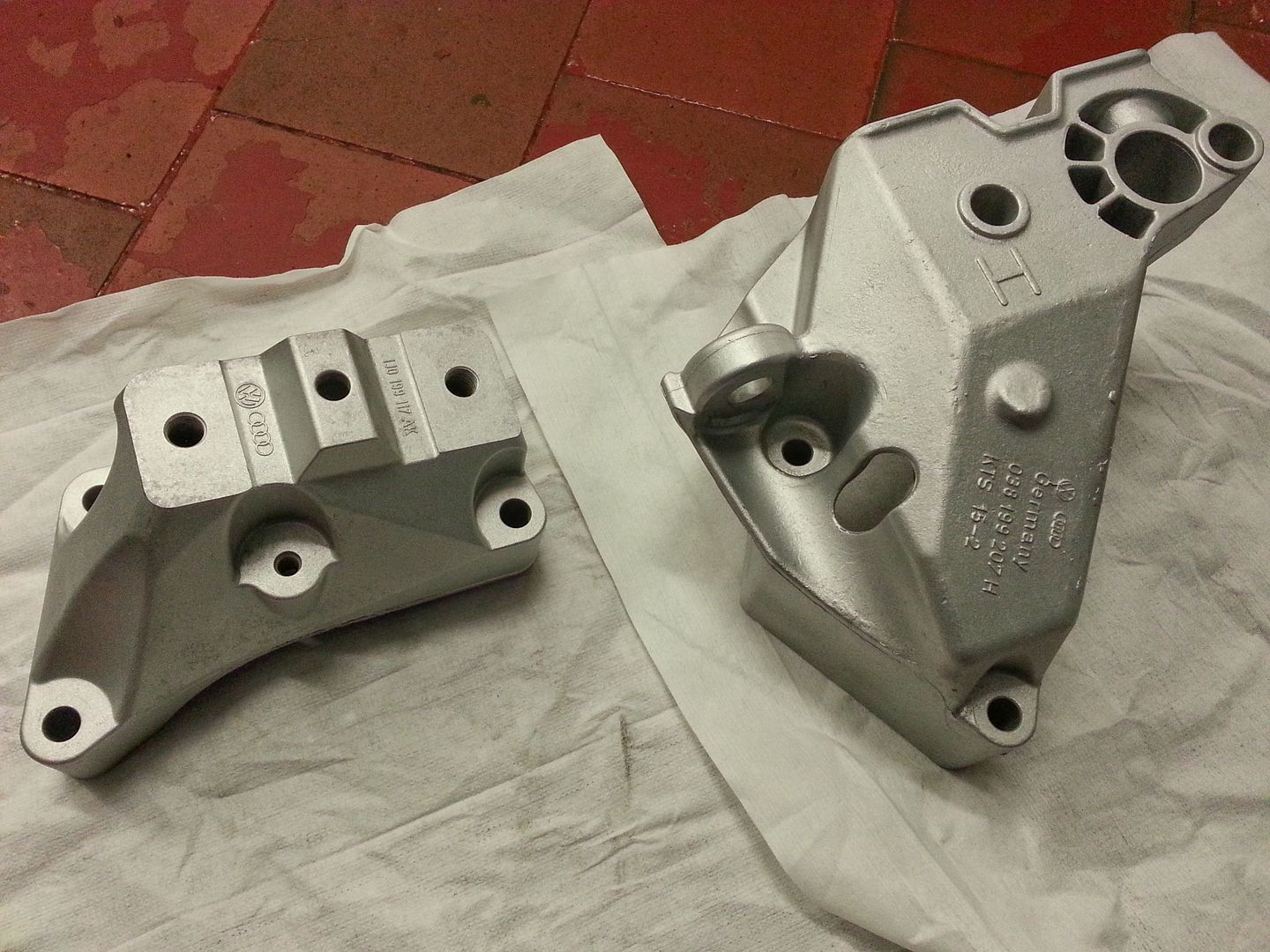

I also decided to replace all the engine mount bolts as they are supposed to be a one use affair but I am still on the originals so all things considered they are being retired...

Mounts waiting to be blasted for painting

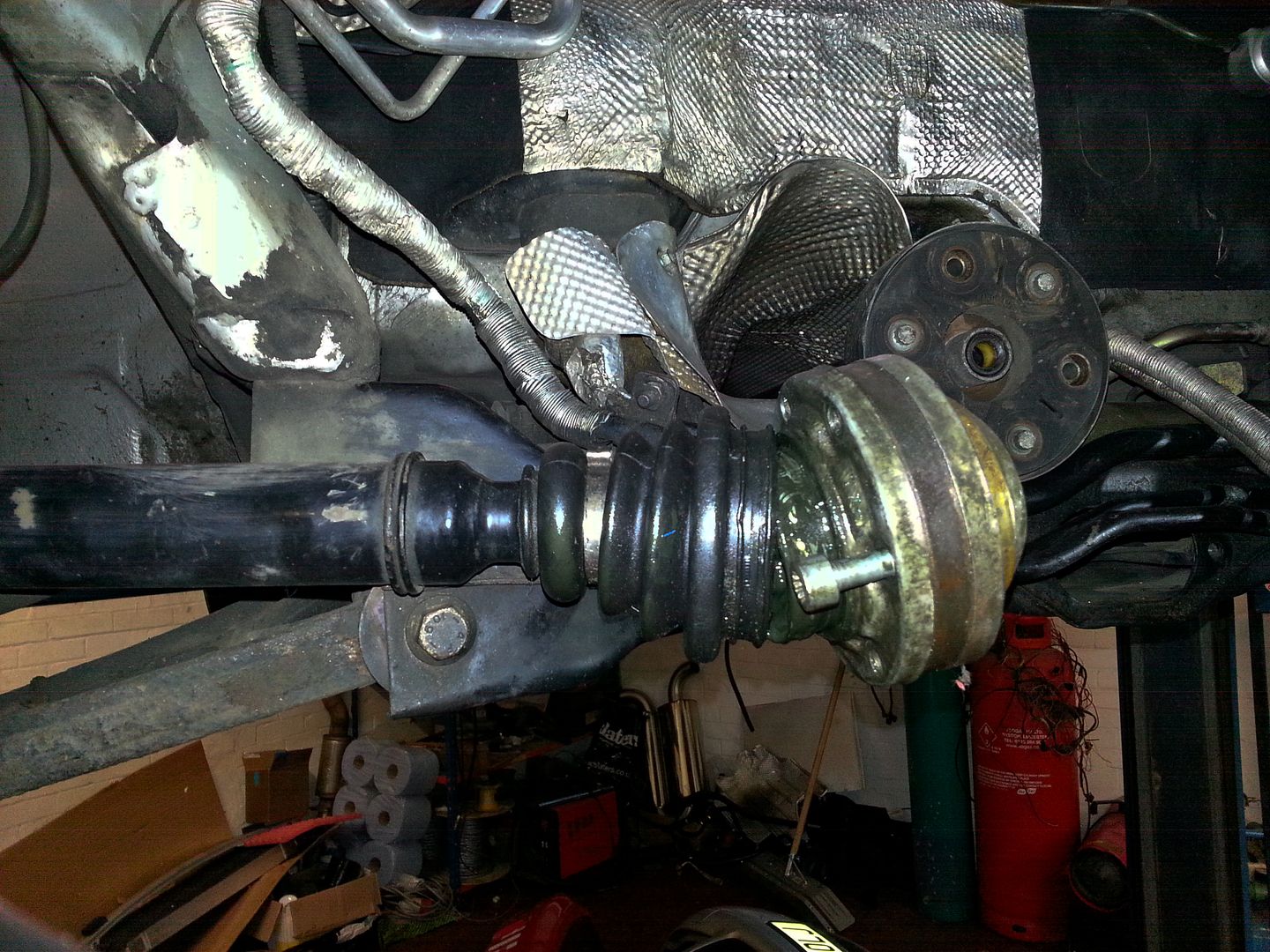

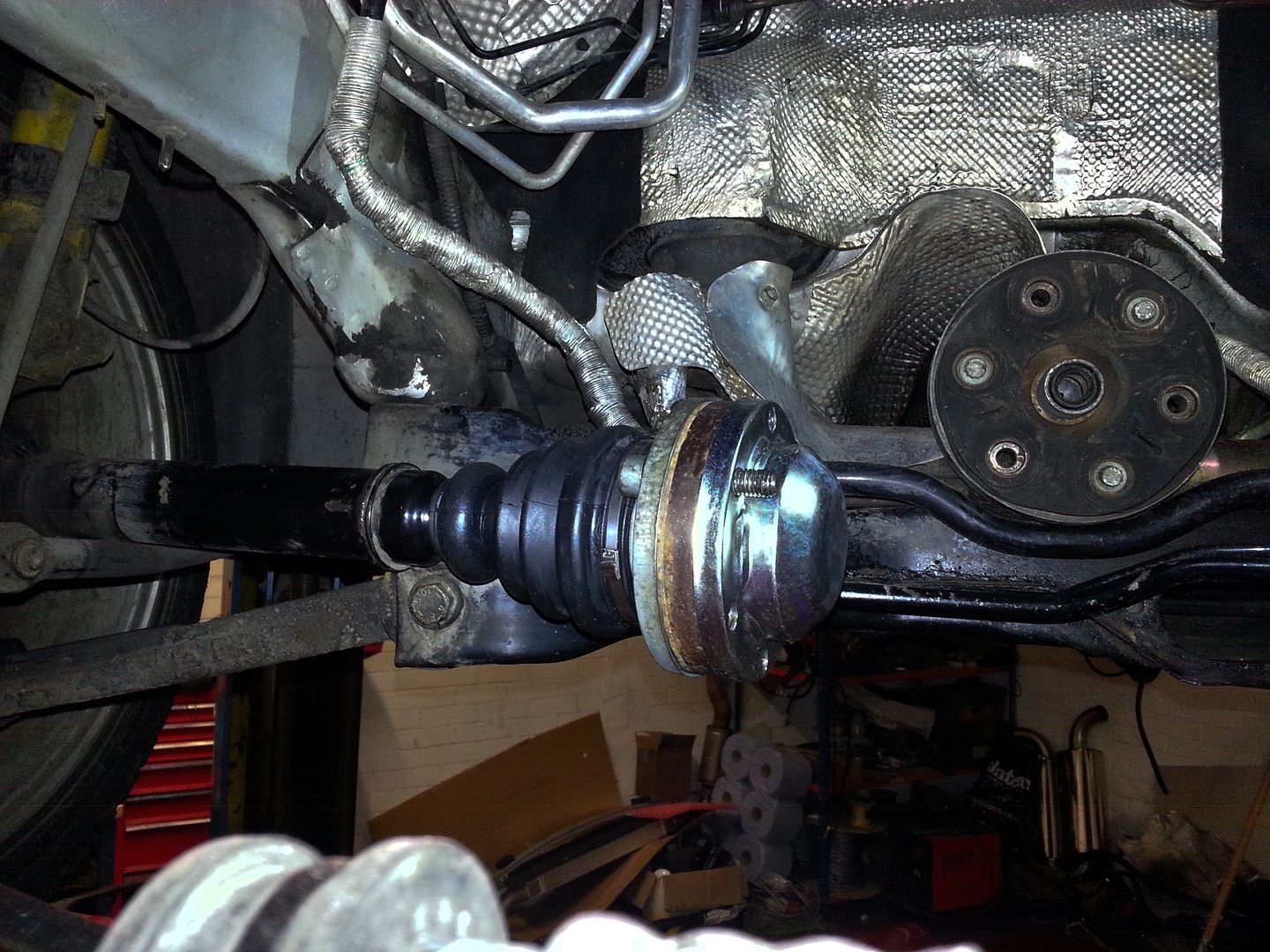

Last job of the day is to change the inboard CV boot... I didn't remove the shaft tis time as to be fair I wasn't struggling for access...

Cleaned the joint of grease (that stuff gets everywhere!!!) and refitted with new grease and the new boot...

Greased up the back of the joint and fitted the new cap...

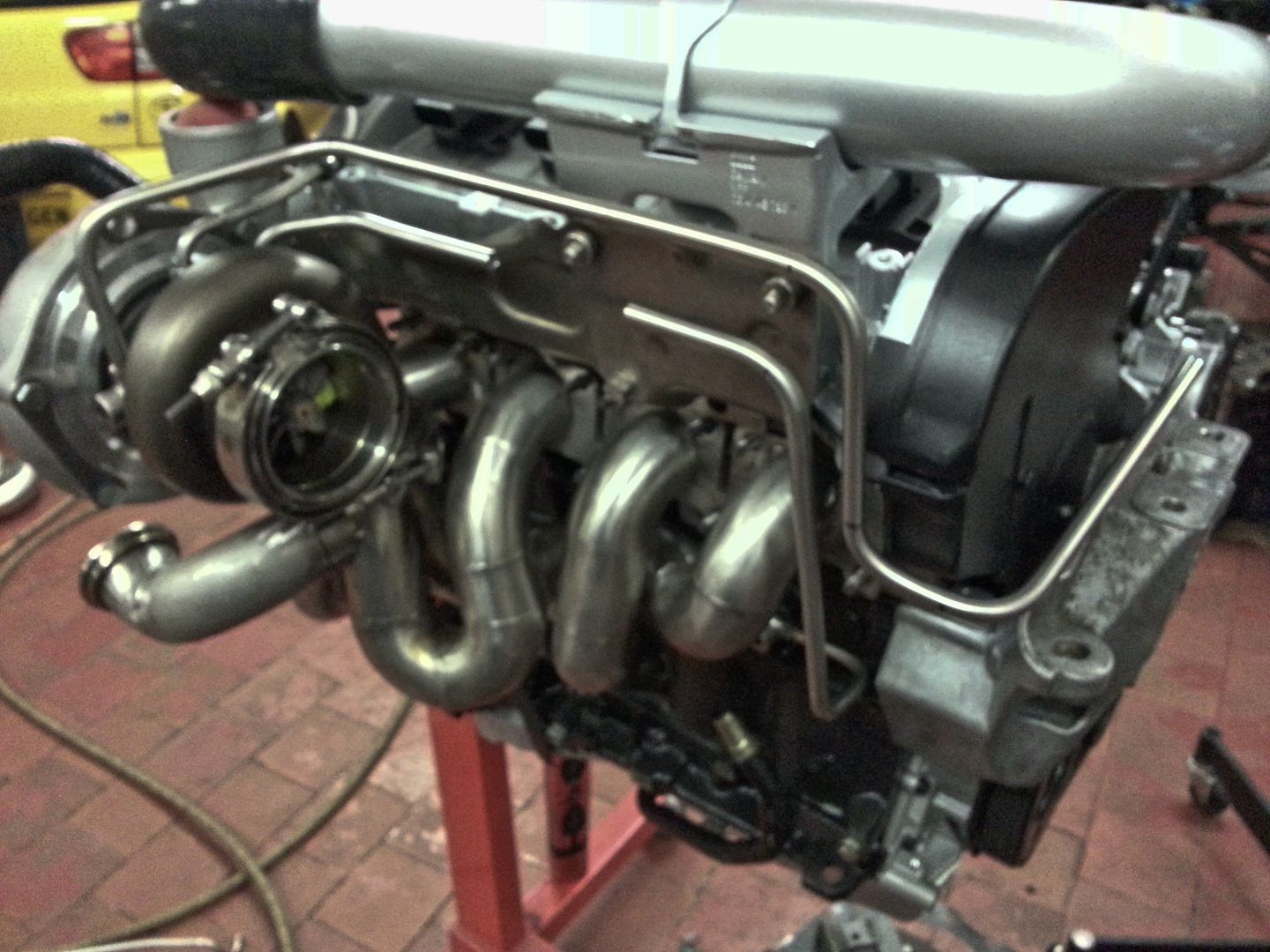

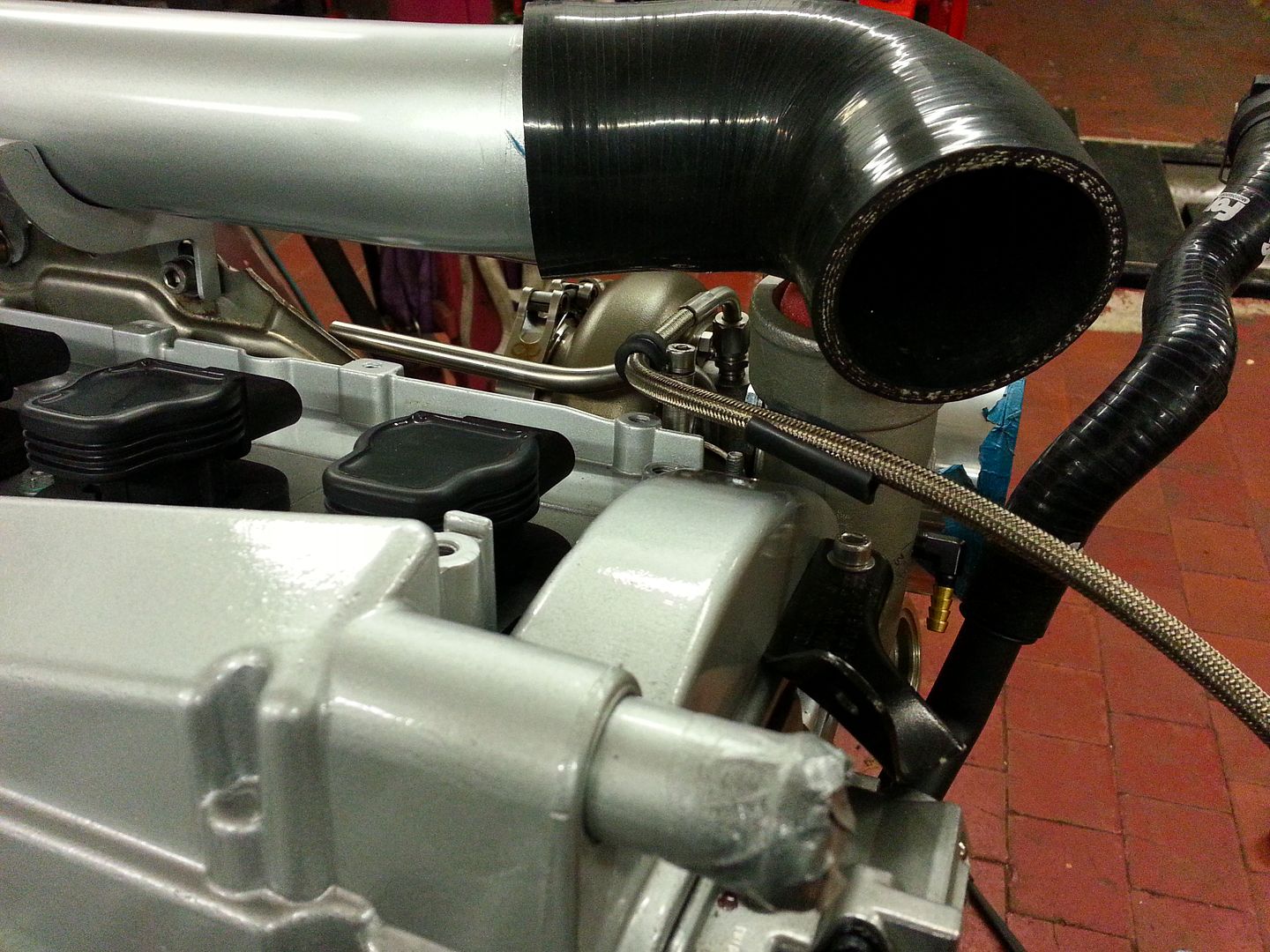

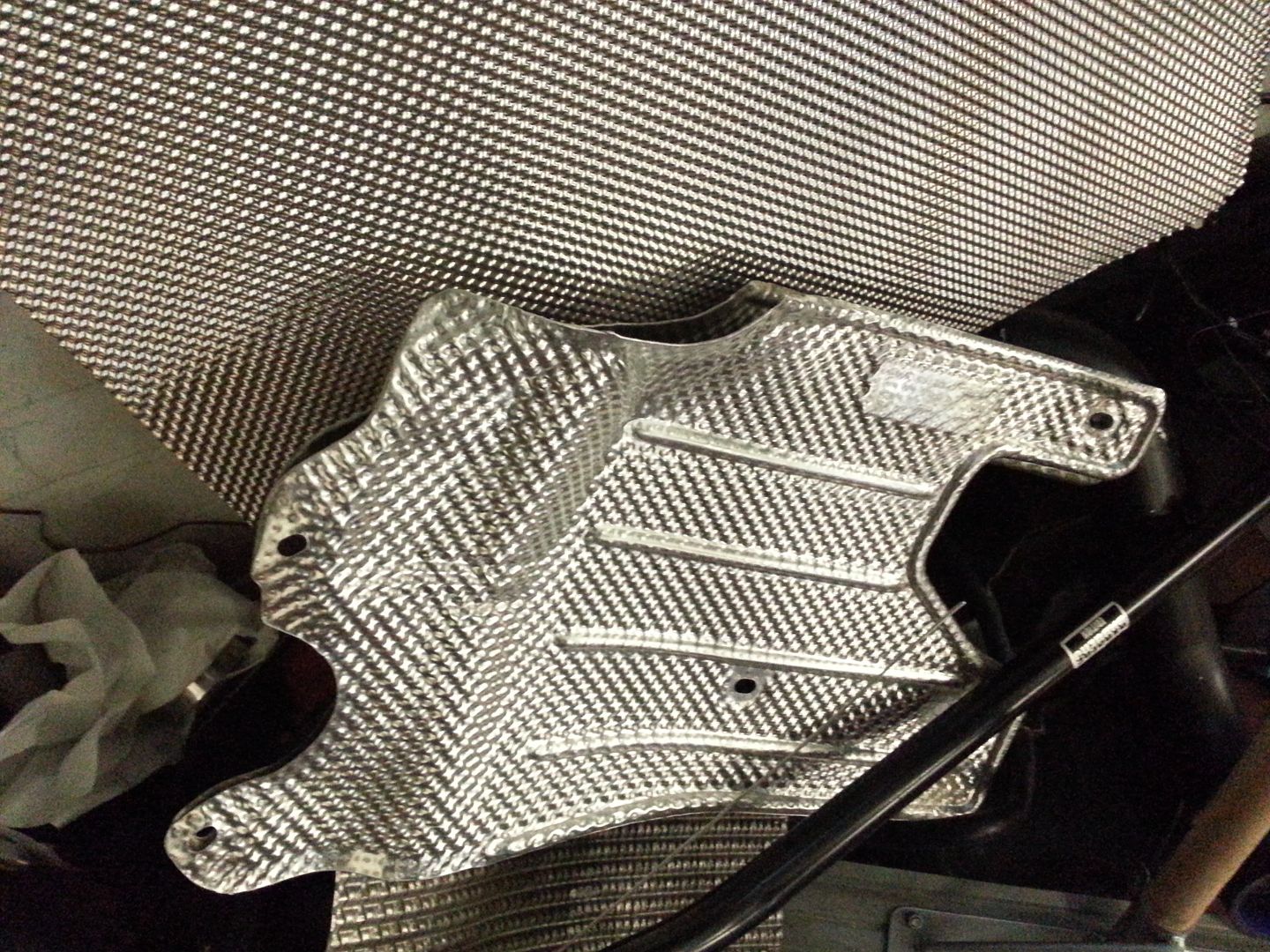

So thats it for now... a few more little jobs and a bit more fabrication left to do... still waiting on a few parts... manifold is having the last bits welded up so should be back soon then I can see if I have any money left to ceramic coat it lol... have ordered a replacement OE heat shield which I am hoping will arrive soon as it was on back order...

Might get a bit of paint on the box tomorrow morning as I have other stuff to do in the afternoon... Tuesday I am off to pick up the wheels from the powder coaters... hopefully they will have come out ok but tbh the damage on one rim might not be easy to sort..

No matter... I am keeping an eye out for another set of RSTT's with a mind to get them perfect..

<tuffty/>