With Christmas upon us, for me, it usually means that I have two or so weeks off over the festive season. Beyond catching up with family and friends, I’m hoping that I’ll get a few days spare to start a few bits and bobs on the car. Generally, the car is running well without any present issues or concerns other than the weather is pants and the car is

filthy; I’m sure we all find ourselves in a similar position… Role on spring…

Having done a bit of digging on the net, as John (CupraMVR) is using, I decided to buy a set of Pulstar Pulse Plugs - BE1-I-Series Iridium. They were going cheap on eBay, so I thought why not. As a point for reference, the BE1-I is the correct fitment for VAG engines.

I’ll probably fit them in the spring once the roads improve; this is when I’ll hopefully (finally) get it mapped so, along with everything else, it should feel a little more lively than its’ standard map.

So the plans for the next couple of weeks are to finally finish off the engine bay. Now that the induction set-up is configured and working well, I’d like to turn my attention to the plastics. The S3 Strut Brace was powder-coated last summer along with all the nuts and bolts having being replaced with SS ones. The hoses are all done and all that needs to be polished, has been.

As you will perhaps know, I sprayed my covers at the beginning of last year and generally, the finish has held up well to the harsh temperatures within the bay.

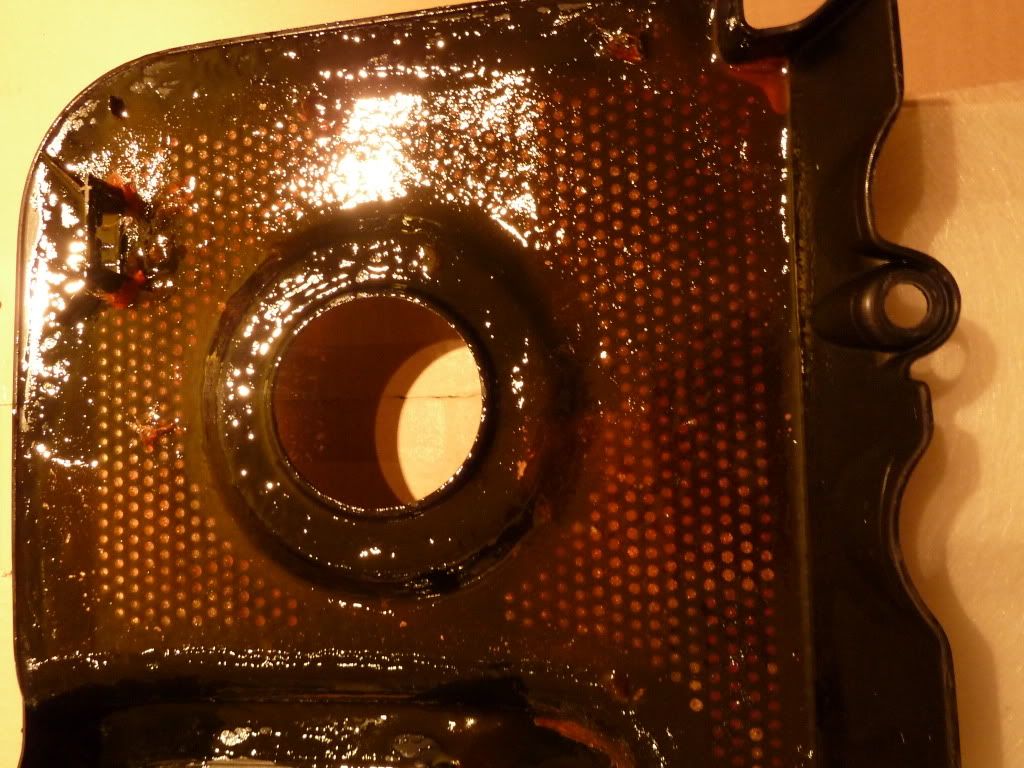

Here's a pic.

However, I’ve never really liked the pimple holes in the main engine cover and the inlet manifold cover. A previous attempt using standard filler did not work due to the heat causing cracks (trial and error…). After becoming a bit wiser, I’m going to use fibre glass and resin to form a backing and fill system. Today, this has been achieved.

I probably won’t be able to start sanding until I break up for Christmas a week on Tuesday, but once smoothed, I’ll use a primer before applying matt black (U-Pol Professional).

For the finish, the lacquer has lasted reasonably well but is starting to look a bit tired. Having done a bit of reading, although I’ve not seen this done, I’ve purchased a 1kg pack of Carbon Fibre High Temperature Epoxy Resin from

www.carbonmods.com and this will be used as the final layer. It is reported that it cures to a perfectly clear finish, is durable and can cope with temps up to 140 deg. Speaking to Darren (D.K.) briefly, he says that it’s user-friendly and gives a good finish, so I’m keeping my fingers crossed.

The same process will be used for the Inlet Manifold cover. As they are cheap, I’ve bought a new cover from Tristan at Seat (as sponsored on SCN). I’ve also ordered a new gasket for the Throttle body to Inlet Manifold as I would like to fit a Throttle body that I’d bought off a mate a while back (improved butterfly piece for flow and is finished nicely in matt black) – drunken purchase so we’ll see…

The battery cover will also receive the same finish.

I’ve also bought some Perspex to try and replicate the S3 engine coolant and windscreen washer cover, with the hope that it will fit without leaving a curved gap at the front as on the S3 cover. I like to have a go at things but this may well be one of my (many) less successful projects. The plan is to use heat to create the bends and indents, and with paint, I hope it’ll look fairly OEM.

A write up of those stages with pictures will follow.

Thanks for reading.

James

Like it!!!

Like it!!!