I noticed my secondary water pump was spinning slower that usual today so I WD40'd the electrical connector up, wiggled it about the revs of the pump went up when the connector was held one way, then it would slow down when pushed very slightly the other way. I got the multimeter out and had a very good 12v feed at the connector. I then decided to 'open up' the motor housing for the pump to investigate further:

I used a small screw driver to bend out the 6 lugs that hold the base on. See pic below:

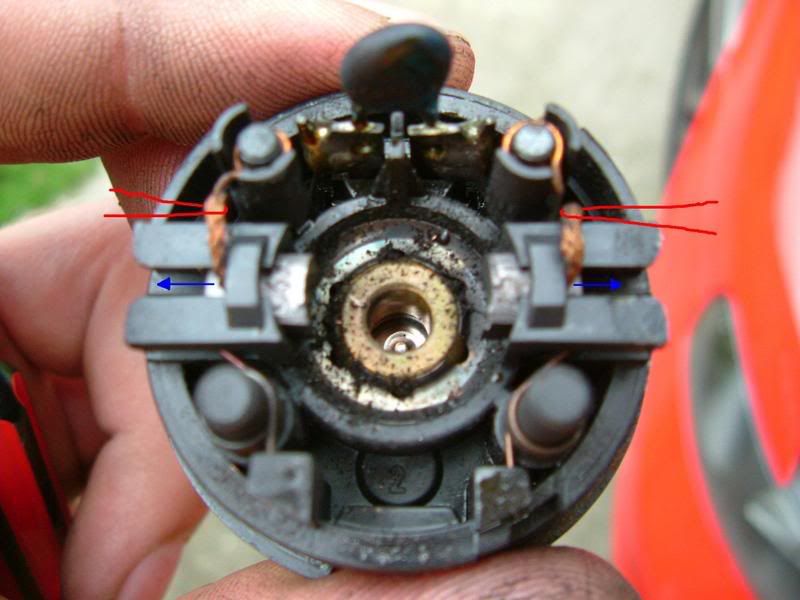

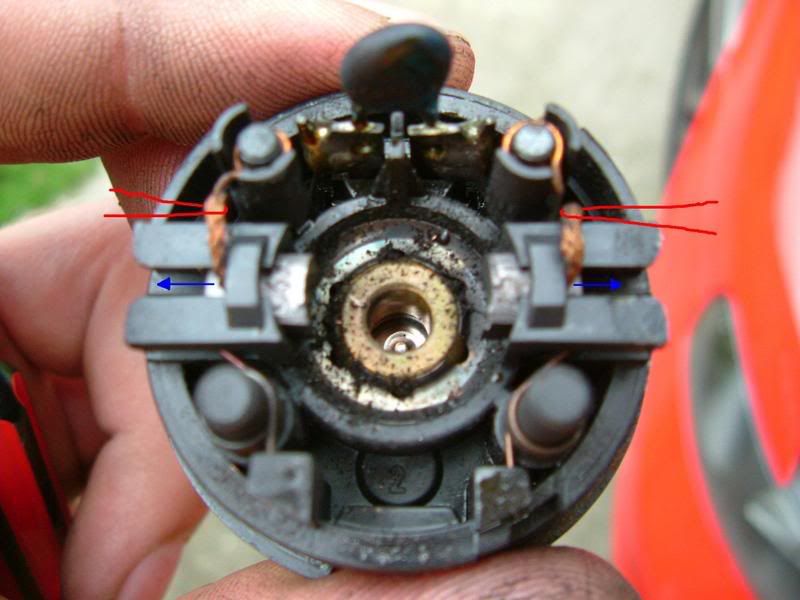

When I got the base off I saw all the dusty crust around the motor / brushes and inside the casing. See below:

I got the multimeter on the terminals on the inner side of the base to check voltage was getting into the motor, all was ok. So it was all the dust and dirt clogging up the motor. I sprayed a load of electrical contact cleaner in there, spun the motor with my fingers to work it around a bit then turned the pump upside down for the dirty residue to drain out. After cleaning the whole unit up inside I gave it a spraying of WD40. Now onto getting the base unit back on: I used a bit of cotton thread (marked in red) and wrapped it around the wires connected to the two brushes to pull them apart enough to get them onto the motors shaft:

Once you've got the base back on pull the thread out of the motor assembly and rebend the metal lugs of the casing back onto the plastic base. Once this was done my pump worked fine and the speed was fast and very consistent, just how it should be. This whole process took me less than 30 minutes. It really is a simple fix.

I used a small screw driver to bend out the 6 lugs that hold the base on. See pic below:

When I got the base off I saw all the dusty crust around the motor / brushes and inside the casing. See below:

I got the multimeter on the terminals on the inner side of the base to check voltage was getting into the motor, all was ok. So it was all the dust and dirt clogging up the motor. I sprayed a load of electrical contact cleaner in there, spun the motor with my fingers to work it around a bit then turned the pump upside down for the dirty residue to drain out. After cleaning the whole unit up inside I gave it a spraying of WD40. Now onto getting the base unit back on: I used a bit of cotton thread (marked in red) and wrapped it around the wires connected to the two brushes to pull them apart enough to get them onto the motors shaft:

Once you've got the base back on pull the thread out of the motor assembly and rebend the metal lugs of the casing back onto the plastic base. Once this was done my pump worked fine and the speed was fast and very consistent, just how it should be. This whole process took me less than 30 minutes. It really is a simple fix.

Last edited: