Cost aside, what would be the best possible [and maybe most straight forward] AWD/4WD set up that could be fitted to a Seat Leon [track] car?

Am aware some have fitted parts from S3 but understand haldex may not be best system and it tends to under steer similar to a FWD only due to it's more FWD than RWD bias?

Would a permanent and equal front/rear drive system be the best and possible to achieve?

Also is there an any actual difference between what people call a AWD or 4WD system?

Hi Rob, i did loads of research before converting mine and the best you'll get is a 50/50 torque split..... this is by fitting any of the vw 4wd / awd traverse systems.

Impreza's / EVO's use adjustable centre diffs and are designed in such a way that the supplied torque is delivered to the centre diff then shared out to which ever axle so they can vary the power to the rear wheels (this allows them to run higher levels to the rear (i think my mates STi can run 70/30 bias to the rear - we don't have a centre diff design for our transversally mounted engines.... ours simply take drive from the front diff crown wheel and put it through a simple bevel box to change it through 90 degrees.

Audi quattro's (longitudinally mounted ones - not s3 or TT) use a similar design to the impreza's etc where you could make them bias to rwd..... they use Torsen diffs.

To get this done right you need to really mount the gearbox behind the front wheels... i think thats why the system isn't used on our transverse applications.

Due to the front engined design of the car and even with a 50/50 split, the car will inherently try and understeer a bit - but in a different way and at much higher speed than a fwd version of the same car.

Basically if you want 4wd your stuck with the haldex system or a massive project to fit an engine longitudinally and the power train. Or look into retrofitting Evo running gear.

Your probably already aware of how the Haldex system works, but in case you don't ----

So as we already know the propshaft is being driven by the transfer box which is turn being drive by the gearbox.....

In a OEM haldex equipped car the Haldex ecu uses information supplied to it via the can-bus system..... sensors include - abs sensors, throttle position, steering angle, acceleration etc etc...

Now the haldex ecu will decide when to lock the diff based on it's current information it's getting.

If the ecu wants to lock the diff it moves a small stepper motor which in turn moves a hydraulic proportioning valve.

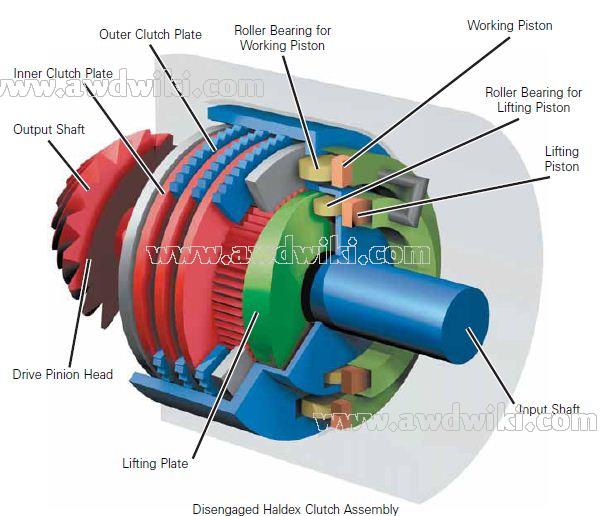

The haldex system is quite simply put - a electro-hydraulic clutch.....

On the first generation Haldex systems they rely on wheel slip to lock - this isn't just a electronic requirement of the abs sensors but also a mechanical requirement.... the haldex clutch is made up of clutch plates that need to be forced together to enable drive to the rear wheels. The way they are forced together is by oil pressure - this oil pressure is first produced by the slipping action between the input and output shafts of the clutch assembly.

Over view of the clutch assembly -

Here is a simplified view of how the oil pump works -

Pics & further reading from -

http://www.awdwiki.com/en/haldex/

Modifying the Haldex system -

There are performance haldex controllers (blue controllers etc) that can change the behaviour of the clutch system - these still use all the oem signals etc but the can lock sooner or stay lock under braking etc for added stability / engine breaking.

The only

problem with these are the car has to have had a functioning haldex system already..... this could be an issue if you do the conversion.

There are also standalone haldex controllers that don't utilise the OEM sensors etc and are designed for people running conversions. You can normally turn the system on / off and use different settings for race / street / drag etc.

I think these are around £700

There is also a simple mechanical hydraulic valve that can be used which removes the haldex ecu and overs a varying level of bias up to 50/50.

They can also be supplied with a switch so you can release the drive when using the handbrake / reversing / or to save fuel.

These are around £300.

I have been looking into this quite a bit myself and i intend on stripping my haldex down and designing a part to replace the clutch plates with a solid permanent drive.... so bin all the gismo's and have 50% to the ear all the time.

This of course would make dyno'ing the car difficult etc.

As for which models to use for the conversion.... any mk4 golf 4 motion / r32.. or audi A3 quattro or S3.... just not the Audi TT as the propshaft is too short and the boot floor is totally different.