A quick review of lasts week's details - lots of pics

Monday

A trip out of Rochdale today, and a drive north to Lancaster.

Here's the car on my 9am arrival:

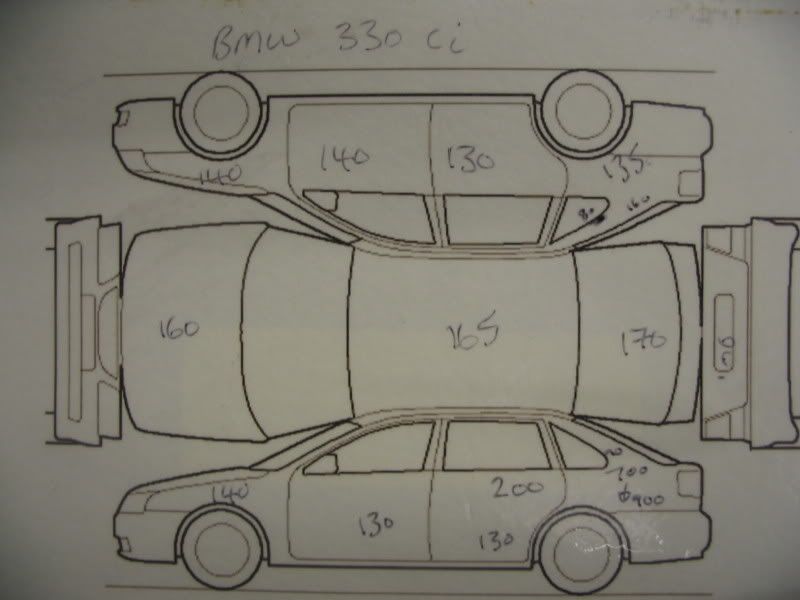

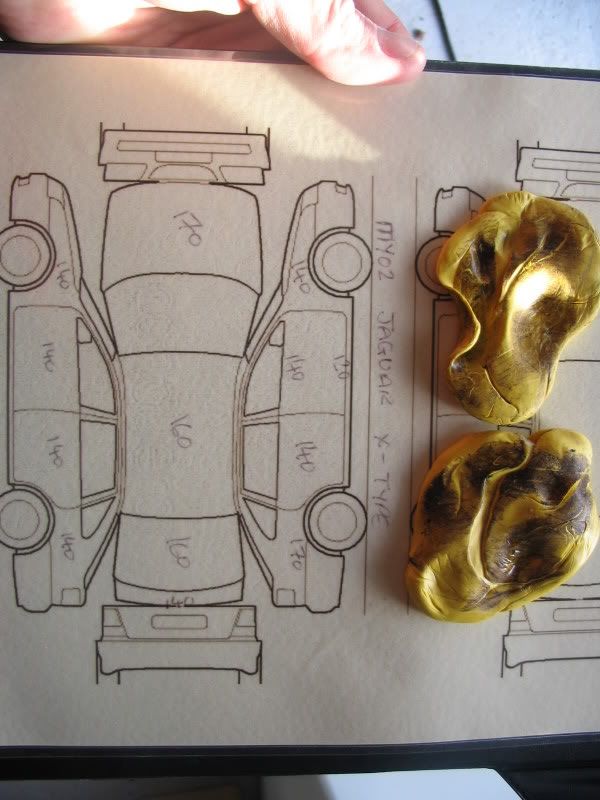

First job was the Dp foam, left to sit for a couple of mins, and rinsed off, then as it was still pretty bad, DP'd it again, and used the one buscket rinse. The alloys and araches saw some APC to help me out with getting then clean. Rinsed again, and then used the DP foam as lub to clay using DP clay. DP clay is pretty aggresive, so wanted lots of lub so as to not get any marring. Once all done, and rinsed, again!, dried with Cobra guzzler, taped with 3m and PDG readings taken.

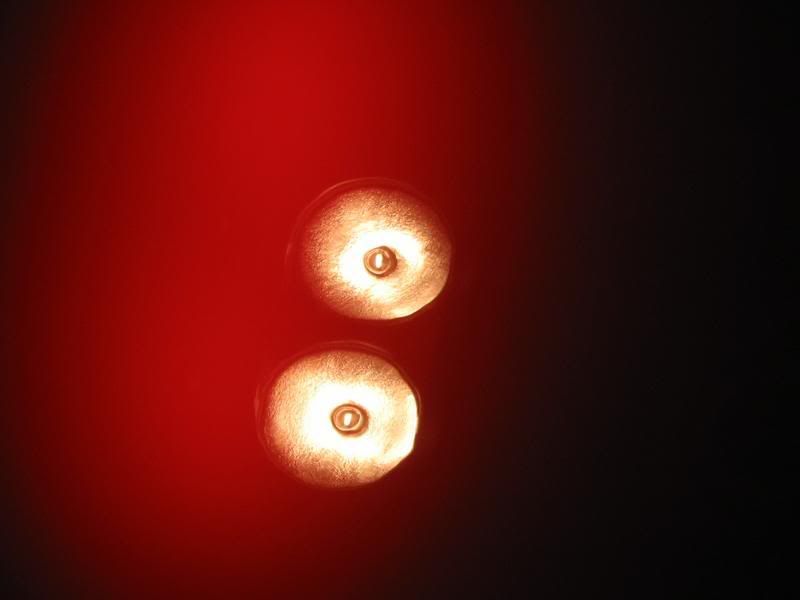

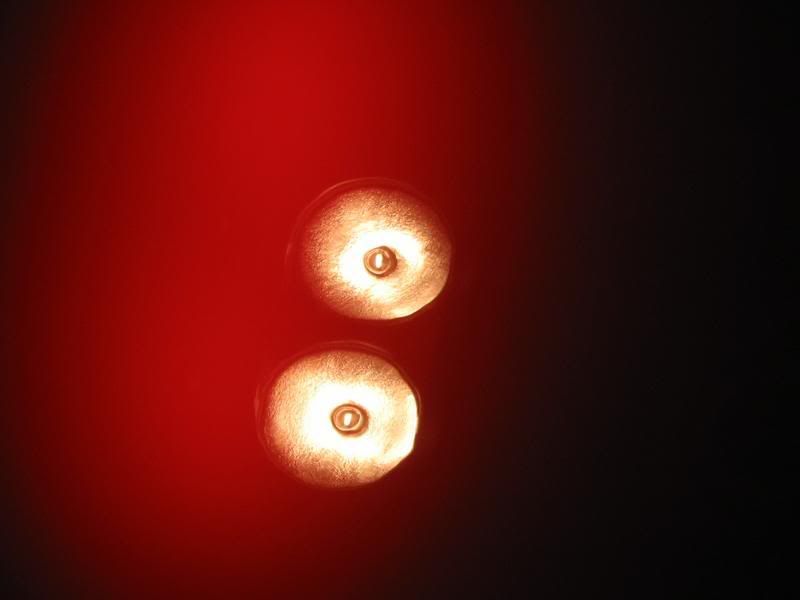

Next up, the halogens and the swirls and scratching.

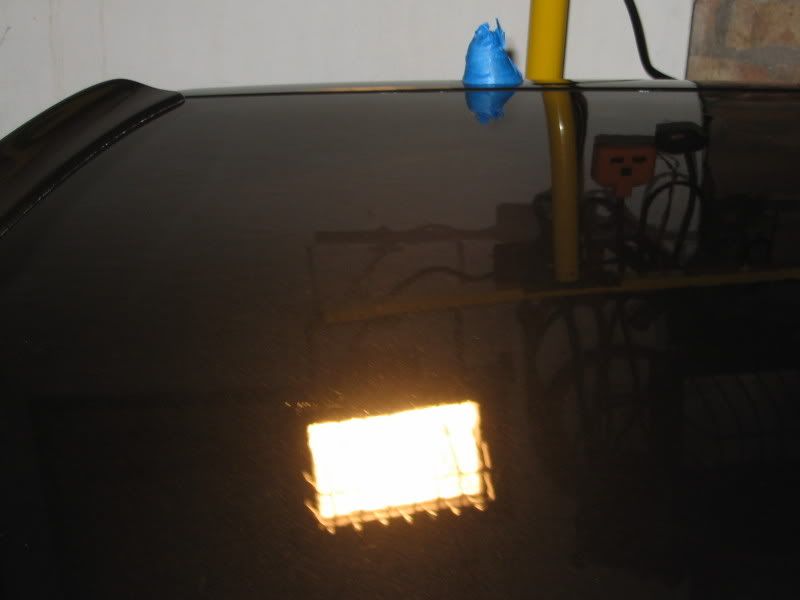

Here is the swirling shot:

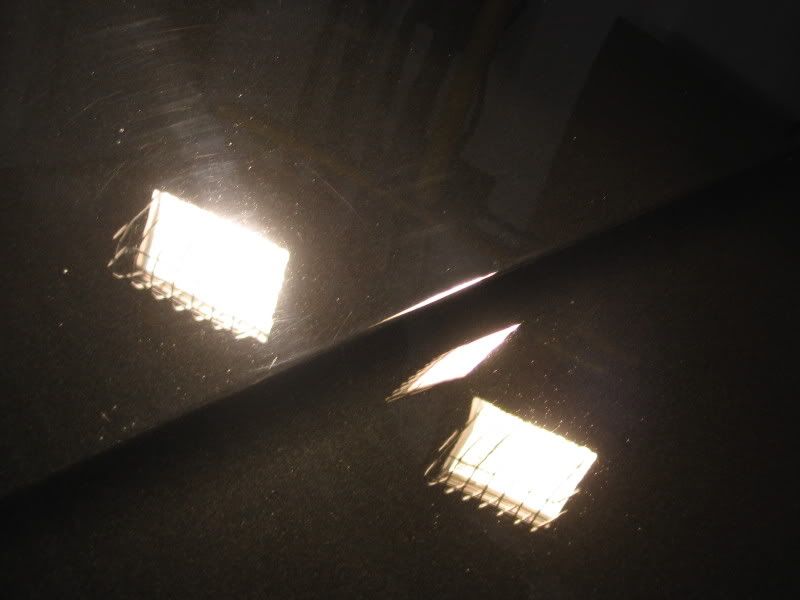

and now in close for the scratches:

No messing around, out with the Metabo, a wolfgang polishing pad and the Pinnacle SR. Worked at 700rpm, swirls gone. Scatching however still very evident. What followed was a good hour or so of me playing with technique,pad and product combos trying to find the lightest combo to retify and resolve. In the end I stuck with the Polishing pad, and used Pinnacle Advanced Swirl Remover at 1500 rpm. This was then followed with another Polishing pad and Pinnacle Advanced Finishing Polish at 1100rpm.

Next, using the PC, a finishing pad and Clearkote red Moose Glaze, applied at speed 2 to allow a nice light glazing. This was then topped with DP Max Wax. Alloys sealed with Megs #20, glass cleaned with Stoners Invisble Glass, and Tyres with Armor All gel.

Monday

A trip out of Rochdale today, and a drive north to Lancaster.

Here's the car on my 9am arrival:

First job was the Dp foam, left to sit for a couple of mins, and rinsed off, then as it was still pretty bad, DP'd it again, and used the one buscket rinse. The alloys and araches saw some APC to help me out with getting then clean. Rinsed again, and then used the DP foam as lub to clay using DP clay. DP clay is pretty aggresive, so wanted lots of lub so as to not get any marring. Once all done, and rinsed, again!, dried with Cobra guzzler, taped with 3m and PDG readings taken.

Next up, the halogens and the swirls and scratching.

Here is the swirling shot:

and now in close for the scratches:

No messing around, out with the Metabo, a wolfgang polishing pad and the Pinnacle SR. Worked at 700rpm, swirls gone. Scatching however still very evident. What followed was a good hour or so of me playing with technique,pad and product combos trying to find the lightest combo to retify and resolve. In the end I stuck with the Polishing pad, and used Pinnacle Advanced Swirl Remover at 1500 rpm. This was then followed with another Polishing pad and Pinnacle Advanced Finishing Polish at 1100rpm.

Next, using the PC, a finishing pad and Clearkote red Moose Glaze, applied at speed 2 to allow a nice light glazing. This was then topped with DP Max Wax. Alloys sealed with Megs #20, glass cleaned with Stoners Invisble Glass, and Tyres with Armor All gel.

Last edited: