Welcome to my guide for replacing the rear pads on a 2017 Leon with an electric parking brake. The job itself is rather simple and straight forward, that being said you must be competent with working on the brake system of your car before you attempt this.

DO NOT PROCEED IF YOU ARE NOT COMPETENT, FAILURE OF THE BRAKING SYSTEM CAN POTENTIALLY KILL.

The following tools and software will be needed to perform this job.

Tools:

7mm Allen bit

Ratchet

Jack & Axle stands

17mm Deep Socket (for wheel nuts)

Locking wheel nut key/remover

Flat bladed screwdrivers

Wire brush

Battery Charger (Optional)

Software:

VCDS or other diagnostic tool with the ability to perform EPB servicing

Materials

Brake pads

Copper/Brake Grease (Optional) - Ceratec brake grease recommended by forum members.

Torque figures:

Carrier Bolts: 90Nm + 90°

Sliding Pins: 35Nm

Wheel Bolts: 120Nm

Step 1

To begin with ensure the car is on a flat, level service and chock the front wheels. You will be disabling the parking brake and raising the rear of the car so it will only be on the front wheels which are not braked, therefore it must be secured to prevent it from rolling. An easy method of chocking is using some bricks in front of the wheels.

Once this has been done, loosen the wheels bolts on both of the rear wheels. Do not remove them.

After this, open the bonnet and remove the cap from the brake fluid reservoir.

Step 2

For this step you are supposed to hook up the car to a battery charger to maintain charge. I did not do this, however you may encounter issues if you do not or if your battery is near end of life. The choice is yours, you have been warned.

With the wheel bolts loosened, turn on the ignition and connect to the car with VCDS. Next, manually disengage the parking brake via the switch, then engage and again disengage.

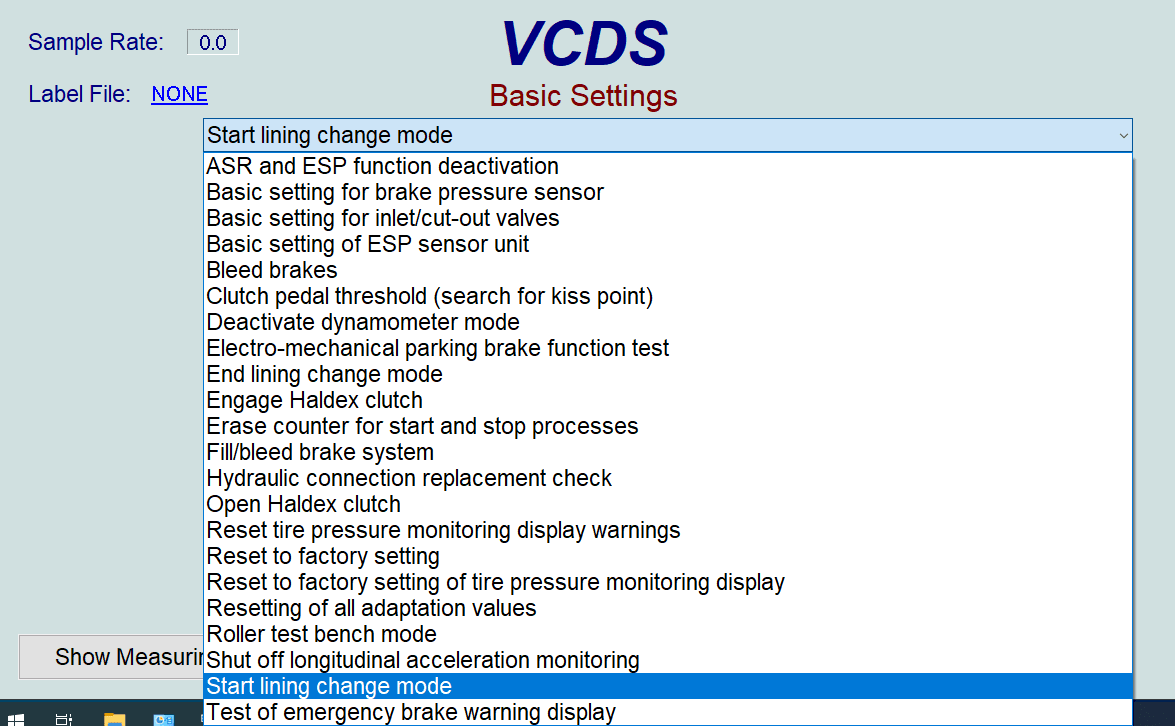

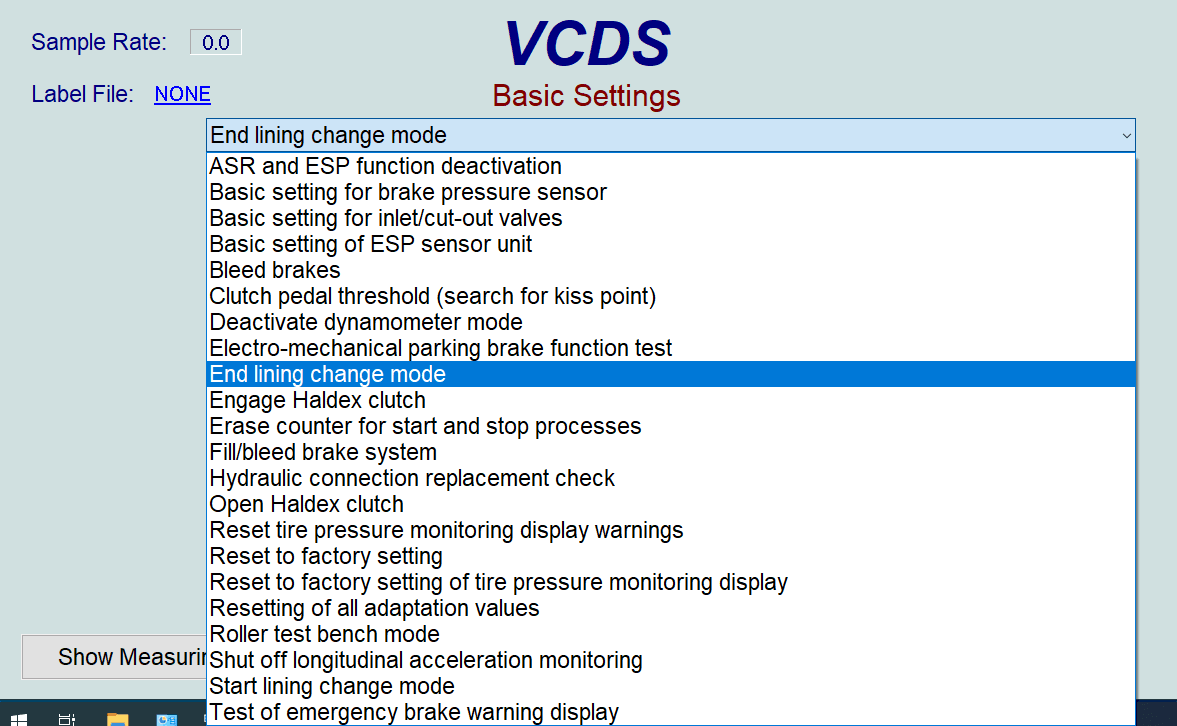

For this particular model of car, the procedure is accessed through the ABS module, on VCDS select 03 - ABS, then select Basic Settings on the right. Click on the drop down menu and select 'Start lining change mode' as seen below:

Once selected click Go!. You will now hear the motors winding themselves in for approx.. 20 or so seconds and VCDS should change to say 'Running'. Once the action is complete the motors will stop and VCDS should change to 'Not Running'. Then click Stop. Next click Done, Go Back and then close the controller menu. If none of the above happens, turn off the ignition, restart VCDS and try the process again.

Once complete, turn off the ignition and leave the charger connected if one is present.

You car may have option 53 - Parking Brake. If this is the case then please follow the instructions on this page:

wiki.ross-tech.com

wiki.ross-tech.com

If you are not using VCDS:

Carista procedure can be found here:

blog.caristaapp.com

blog.caristaapp.com

OBD Eleven - the process should be as follows - Select 53 - Parking Brake - Basic Setting - Channel 7 to release, then Channel 6 to reset after pad replacement. After goto channel 10 and perform a function test.

If anyone who uses the above could confirm to me if this works as expected, I would be most thankful.

Step 3

With the motors retracked, jack the rear of the car in a suitable place. On models with a solid rear beam (Models with 150BHP and below as standard) there is a good point to jack just in front of the rear wheels as seen below:

Once jacked, place an axle stand under the sill and lower the car to ensure safe elevation

Step 4

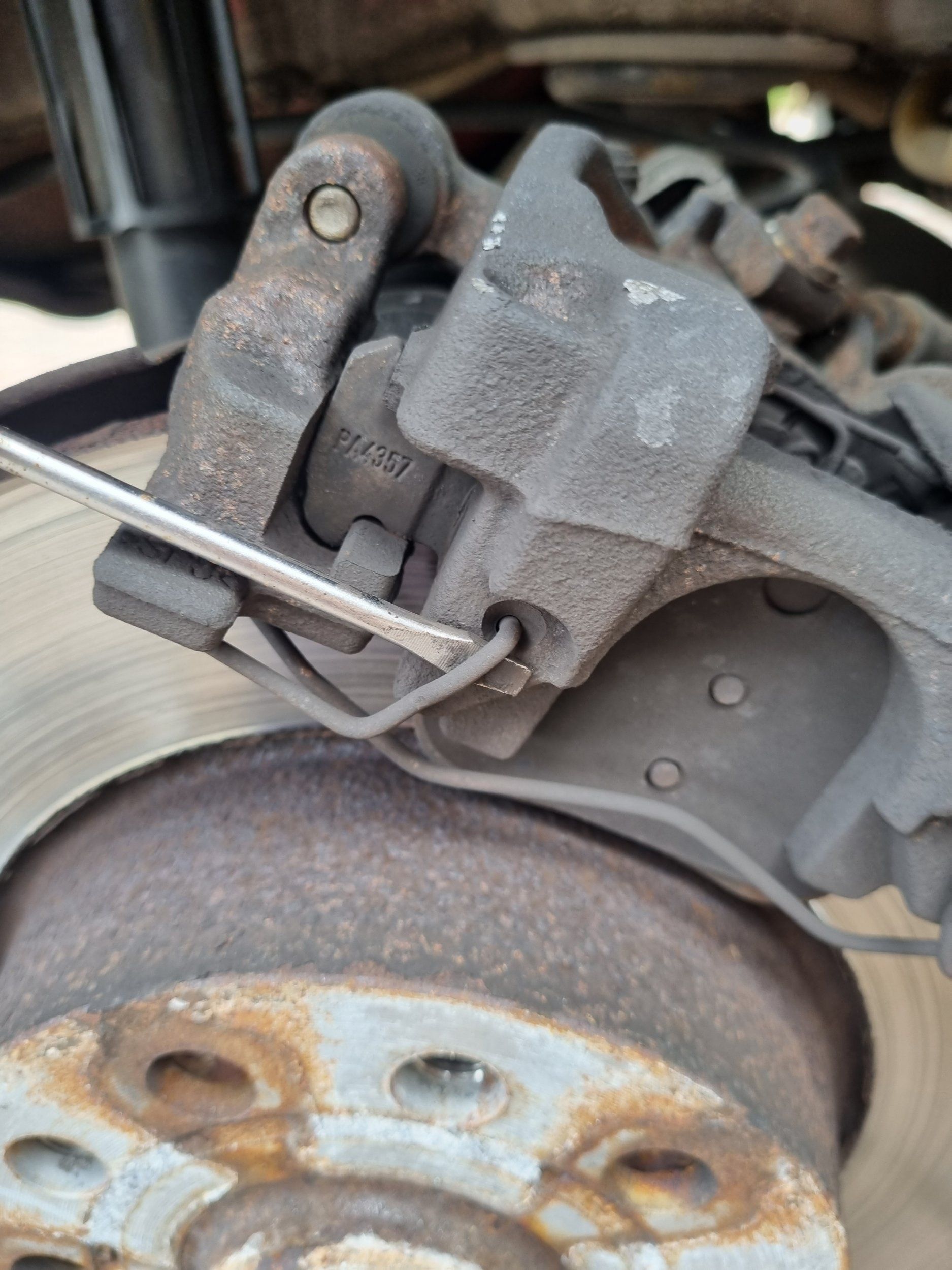

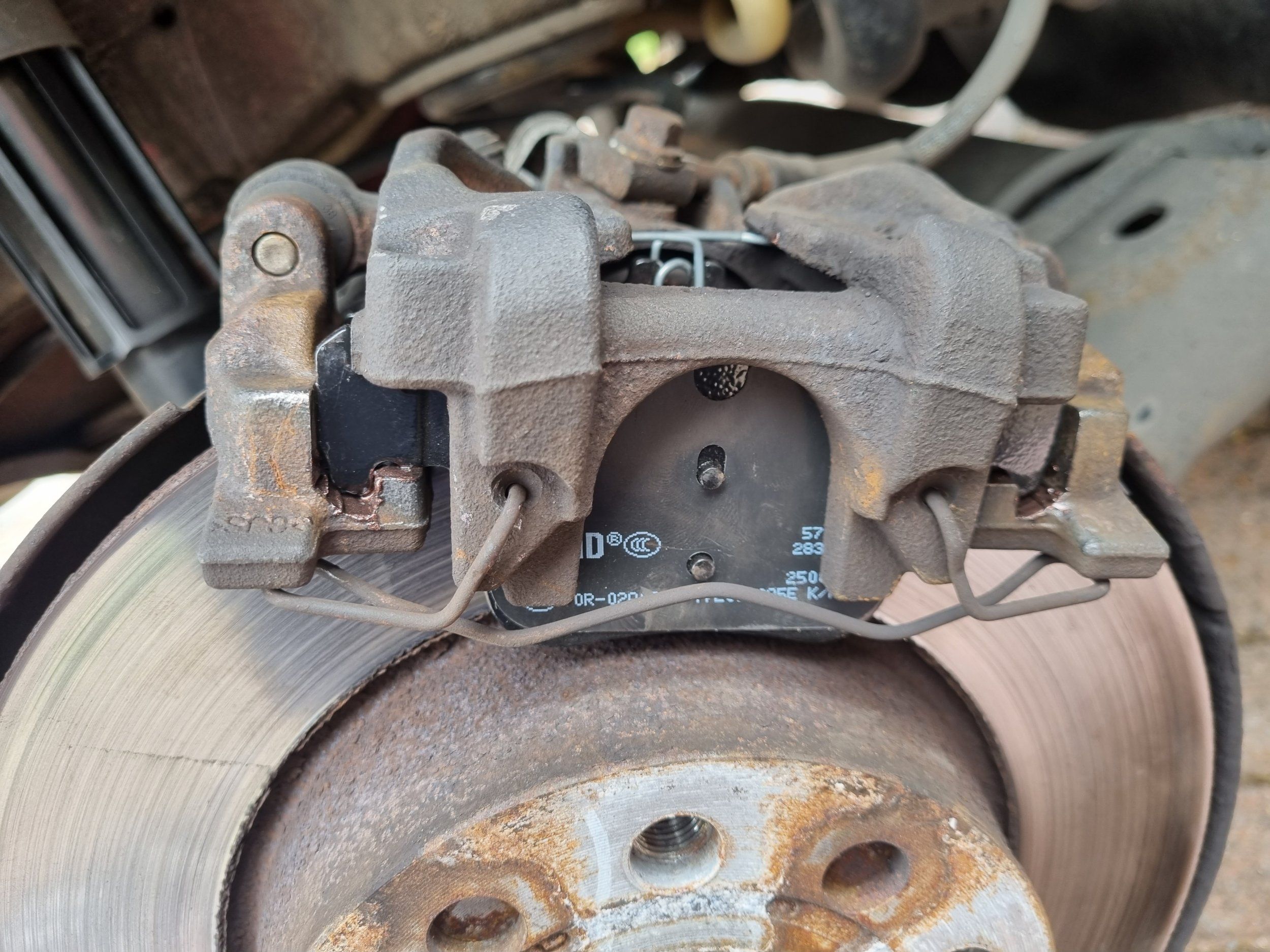

Once raised, remove the bolts from the wheel and take the wheel off. If it is stiff, give the side a hard kick and the wheel should pop off the hub. With the wheel removed, start by removing the retaining clip on the caliper. Simply use a flat bladed screwdriver to pry it off:

With the clip removed, insert the screwdriver in between the edge of the outer pad and the edge of the caliper, and lever the handle towards you. This pushes the piston back into the caliper and allows easy removal. Doing this saves a step later by pushing the piston back in. If you prefer, you can ignore this and reset the piston later with the appropriate tool:

Piston fully retracked and gap between pad and caliper:

Step 5

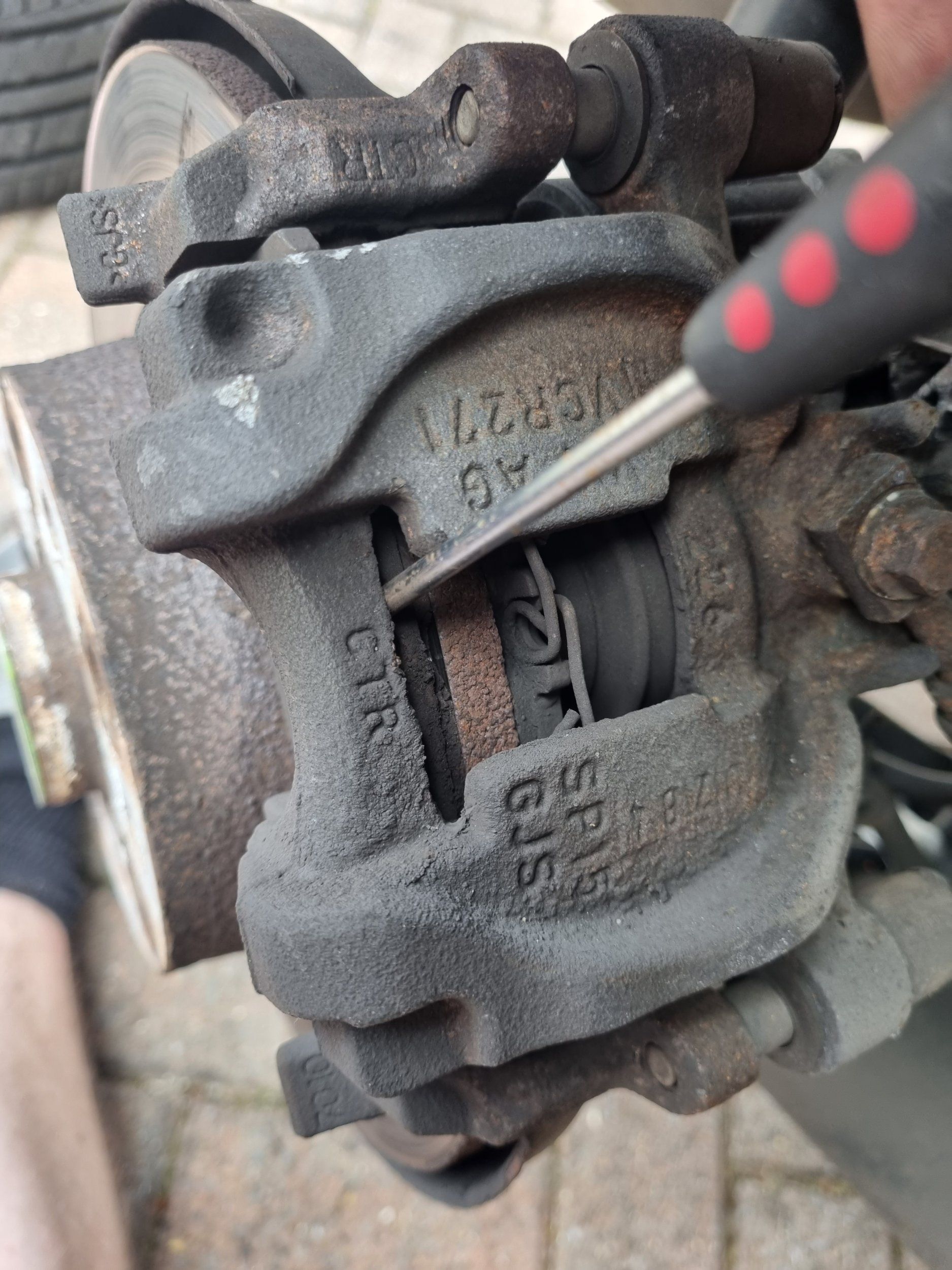

With the caliper loosened and piston pushed back in, remove the protective caps from the housing around the sliding pins at the back of the caliper and then remove the pins using a 7mm allen bit:

Removing the pins:

Lift the brake flexi to gain access to the forward-most pin:

Step 6

With the sliding pins removed, the caliper will lift clear of the carrier allowing the old pads to be removed. With the pads removed, you can now clean up the channels that the pads slide along with a wire brush. I used a wire brush on a drill to achieve this. Be sure to clean the sliding channels on both sides of the disc.

You can also inspect the disc at this point to ensure it is suitable for further use. You need to check for the present of cracks, pitting, uneven wear or other obvious defects. There may be a slight lip around the circumference of the disc. This is acceptable so long as it isn't excessive. An excessive lip (1.5mm+ in width) would indicate the disc has been worn down a lot and may be near/at the end of it's life. In this situation I would recommend replacing the disc.

My discs appear to be in good shape:

If you are also replacing discs, now is the time to remove the carrier and replace the disc. This is not covered in this guide, however everything you need to do after replacement is the same as below. The torque setting for carrier bolts is 90Nm + 90°.

Before:

After:

Step 7

Before installing the new pads, ensure they are correct by comparing them to the old pads:

This next part is optional. I am aware there is debate about the use of grease on brakes when replacing pads. I personally do use copper grease. If you are going to use grease, you only need a very small amount. Sit the new pad into the sliders and make note of the areas where the clips on the edges touch the sliding channels. Then remove the pad and apply a thin amount of grease to that area. I also apply some to the surface of the piston and the surface of the opposite side to the piston - the 2 prongs that go around the rear of the outer pad. Take care not to get any elsewhere or on the braking surfaces of the pads or disc.

Whether or not you have applied grease, you can now fit the pads into the carrier. One pad should have a silver metal clip on top. This pad goes behind the disc. Ensure the pads are inserted correctly with the braking surface facing towards the disc.

Pads installed:

Step 8

With the pads installed you can now replace the caliper. If you did not push the piston back in earlier, then you will need to do this now. Position the caliper over the top of the pads and align the holes for the sliding pins. Ensure the silver metal tabs on the top of the rear pad are flat and rest against the caliper as it is placed on top as seen here:

Before installing the pins, you can clean them up with a wire brush to enable smoother operation. The picture below shows a cleaned pin next to a uncleaned pin:

Insert the pins and tighten them into the caliper with the 7mm allen bit. Ensure you do not cross thread them. You may wish to lightly grease the pins before installing them. Torque the bolt to 35Nm. Remember to replace the protective cap into the housing.

Step 9

With the caliper secured, you can now replace the metal retaining clip:

Step 10

Replace the wheel and install the bolts hand tight. Lower the car and torque the bolts to 120Nm. You may need to chock the rear wheels to do this as the car will roll.

Repeat from step 3 to step 10 for the other side of the car.

Once complete, REPLACE THE BRAKE RESERVOIR CAP.

Step 11

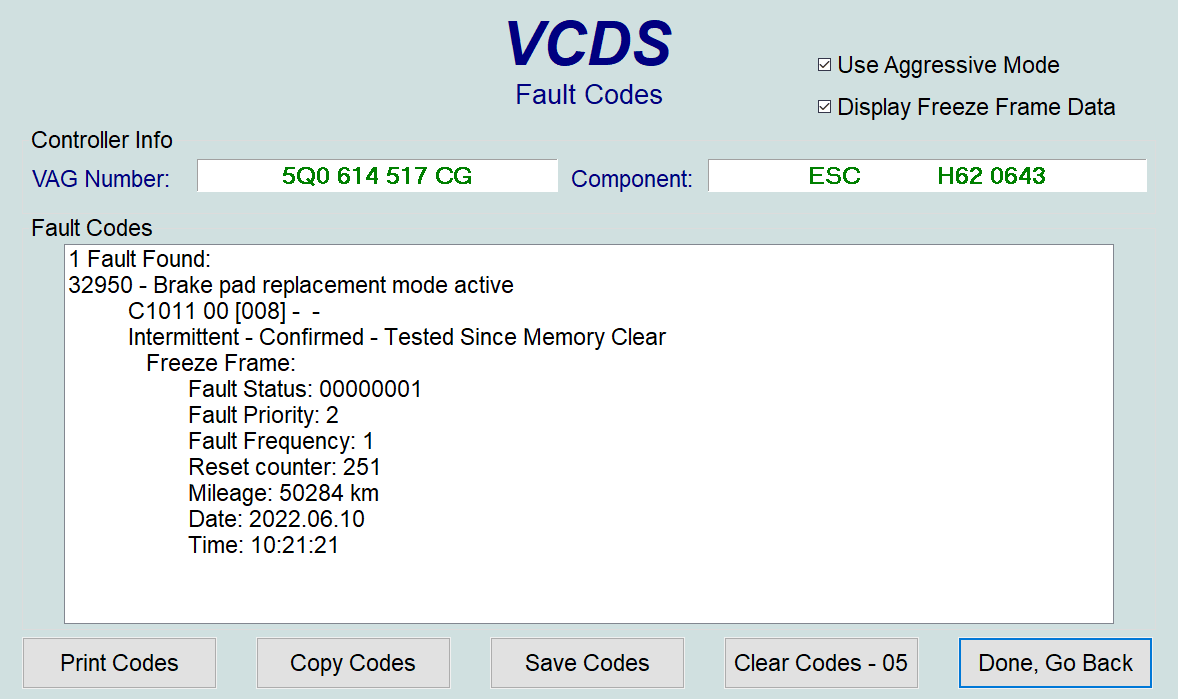

With both sides completed as above, you can now turn the ignition back on and go back to the ABS module menu and select the Basic Settings - 04 menu. From the drop down list select 'End lining change mode' and click Go!. You will again hear the motors winding out. Once they have stopped and the screen says 'Not Running' click Stop and the Go Back. You can now clear any DTC's generated from the procedure in the Fault Code section.

End screen:

DTC created from the process:

Turn off the ignition and then turn it back on. Cycle the parking brake on and off a few times and press the brake pedal. With all of the above complete, you should now be finished. I recommend taking the car for a small drive and testing out the brakes to ensure correct operation. I would also suggest parking on a slight incline and applying the parking brake to ensure it is operating as expected.

You are now complete.

Any questions or suggestions for the guide please feel free to comment.

Lozzy.

DO NOT PROCEED IF YOU ARE NOT COMPETENT, FAILURE OF THE BRAKING SYSTEM CAN POTENTIALLY KILL.

The following tools and software will be needed to perform this job.

Tools:

7mm Allen bit

Ratchet

Jack & Axle stands

17mm Deep Socket (for wheel nuts)

Locking wheel nut key/remover

Flat bladed screwdrivers

Wire brush

Battery Charger (Optional)

Software:

VCDS or other diagnostic tool with the ability to perform EPB servicing

Materials

Brake pads

Copper/Brake Grease (Optional) - Ceratec brake grease recommended by forum members.

Torque figures:

Carrier Bolts: 90Nm + 90°

Sliding Pins: 35Nm

Wheel Bolts: 120Nm

Step 1

To begin with ensure the car is on a flat, level service and chock the front wheels. You will be disabling the parking brake and raising the rear of the car so it will only be on the front wheels which are not braked, therefore it must be secured to prevent it from rolling. An easy method of chocking is using some bricks in front of the wheels.

Once this has been done, loosen the wheels bolts on both of the rear wheels. Do not remove them.

After this, open the bonnet and remove the cap from the brake fluid reservoir.

Step 2

For this step you are supposed to hook up the car to a battery charger to maintain charge. I did not do this, however you may encounter issues if you do not or if your battery is near end of life. The choice is yours, you have been warned.

With the wheel bolts loosened, turn on the ignition and connect to the car with VCDS. Next, manually disengage the parking brake via the switch, then engage and again disengage.

For this particular model of car, the procedure is accessed through the ABS module, on VCDS select 03 - ABS, then select Basic Settings on the right. Click on the drop down menu and select 'Start lining change mode' as seen below:

Once selected click Go!. You will now hear the motors winding themselves in for approx.. 20 or so seconds and VCDS should change to say 'Running'. Once the action is complete the motors will stop and VCDS should change to 'Not Running'. Then click Stop. Next click Done, Go Back and then close the controller menu. If none of the above happens, turn off the ignition, restart VCDS and try the process again.

Once complete, turn off the ignition and leave the charger connected if one is present.

You car may have option 53 - Parking Brake. If this is the case then please follow the instructions on this page:

Working on the Electro-Mechanical Parking Brake (EPB) - Ross-Tech Wiki

If you are not using VCDS:

Carista procedure can be found here:

Changing rear brake pads or discs on VW & Audi models with an electronic parking brake (EPB)

Most new Audi and VW models (and some SEAT and Skoda, too!) have an electronic parking brake (EPB). This adds a lot of convenience for the…

blog.caristaapp.com

blog.caristaapp.com

OBD Eleven - the process should be as follows - Select 53 - Parking Brake - Basic Setting - Channel 7 to release, then Channel 6 to reset after pad replacement. After goto channel 10 and perform a function test.

If anyone who uses the above could confirm to me if this works as expected, I would be most thankful.

Step 3

With the motors retracked, jack the rear of the car in a suitable place. On models with a solid rear beam (Models with 150BHP and below as standard) there is a good point to jack just in front of the rear wheels as seen below:

Once jacked, place an axle stand under the sill and lower the car to ensure safe elevation

Step 4

Once raised, remove the bolts from the wheel and take the wheel off. If it is stiff, give the side a hard kick and the wheel should pop off the hub. With the wheel removed, start by removing the retaining clip on the caliper. Simply use a flat bladed screwdriver to pry it off:

With the clip removed, insert the screwdriver in between the edge of the outer pad and the edge of the caliper, and lever the handle towards you. This pushes the piston back into the caliper and allows easy removal. Doing this saves a step later by pushing the piston back in. If you prefer, you can ignore this and reset the piston later with the appropriate tool:

Piston fully retracked and gap between pad and caliper:

Step 5

With the caliper loosened and piston pushed back in, remove the protective caps from the housing around the sliding pins at the back of the caliper and then remove the pins using a 7mm allen bit:

Removing the pins:

Lift the brake flexi to gain access to the forward-most pin:

Step 6

With the sliding pins removed, the caliper will lift clear of the carrier allowing the old pads to be removed. With the pads removed, you can now clean up the channels that the pads slide along with a wire brush. I used a wire brush on a drill to achieve this. Be sure to clean the sliding channels on both sides of the disc.

You can also inspect the disc at this point to ensure it is suitable for further use. You need to check for the present of cracks, pitting, uneven wear or other obvious defects. There may be a slight lip around the circumference of the disc. This is acceptable so long as it isn't excessive. An excessive lip (1.5mm+ in width) would indicate the disc has been worn down a lot and may be near/at the end of it's life. In this situation I would recommend replacing the disc.

My discs appear to be in good shape:

If you are also replacing discs, now is the time to remove the carrier and replace the disc. This is not covered in this guide, however everything you need to do after replacement is the same as below. The torque setting for carrier bolts is 90Nm + 90°.

Before:

After:

Step 7

Before installing the new pads, ensure they are correct by comparing them to the old pads:

This next part is optional. I am aware there is debate about the use of grease on brakes when replacing pads. I personally do use copper grease. If you are going to use grease, you only need a very small amount. Sit the new pad into the sliders and make note of the areas where the clips on the edges touch the sliding channels. Then remove the pad and apply a thin amount of grease to that area. I also apply some to the surface of the piston and the surface of the opposite side to the piston - the 2 prongs that go around the rear of the outer pad. Take care not to get any elsewhere or on the braking surfaces of the pads or disc.

Whether or not you have applied grease, you can now fit the pads into the carrier. One pad should have a silver metal clip on top. This pad goes behind the disc. Ensure the pads are inserted correctly with the braking surface facing towards the disc.

Pads installed:

Step 8

With the pads installed you can now replace the caliper. If you did not push the piston back in earlier, then you will need to do this now. Position the caliper over the top of the pads and align the holes for the sliding pins. Ensure the silver metal tabs on the top of the rear pad are flat and rest against the caliper as it is placed on top as seen here:

Before installing the pins, you can clean them up with a wire brush to enable smoother operation. The picture below shows a cleaned pin next to a uncleaned pin:

Insert the pins and tighten them into the caliper with the 7mm allen bit. Ensure you do not cross thread them. You may wish to lightly grease the pins before installing them. Torque the bolt to 35Nm. Remember to replace the protective cap into the housing.

Step 9

With the caliper secured, you can now replace the metal retaining clip:

Step 10

Replace the wheel and install the bolts hand tight. Lower the car and torque the bolts to 120Nm. You may need to chock the rear wheels to do this as the car will roll.

Repeat from step 3 to step 10 for the other side of the car.

Once complete, REPLACE THE BRAKE RESERVOIR CAP.

Step 11

With both sides completed as above, you can now turn the ignition back on and go back to the ABS module menu and select the Basic Settings - 04 menu. From the drop down list select 'End lining change mode' and click Go!. You will again hear the motors winding out. Once they have stopped and the screen says 'Not Running' click Stop and the Go Back. You can now clear any DTC's generated from the procedure in the Fault Code section.

End screen:

DTC created from the process:

Turn off the ignition and then turn it back on. Cycle the parking brake on and off a few times and press the brake pedal. With all of the above complete, you should now be finished. I recommend taking the car for a small drive and testing out the brakes to ensure correct operation. I would also suggest parking on a slight incline and applying the parking brake to ensure it is operating as expected.

You are now complete.

Any questions or suggestions for the guide please feel free to comment.

Lozzy.